Robot waterbase applicator - maintenance, Polar and non-polar solvents, Applicator disassembly – Ransburg Evolver Water Applicator 78863-90, 78863-60 User Manual

Page 23: Head removal/repair

19

Robot Waterbase Applicator - Maintenance

Amyl Acetate

Methyl Amyl Acetate

Toluene

Xylene

High Flash Naptha

Mineral Spirits

Non-Conductive (Non-Polar)

POLAR AND NON-POLAR SOLVENTS

Moderately Conductive

Extremely Conductive (Polar)

Methyl

Isobutyl Ketone

Ethyl Acetate

Methyl Ethyl Ketone

Butyl Carbitol

Methanol

Carbitol

Diacetone

Butyl Alcohol

Acetone

Butyl Cellosolve

>

An electrical discharge or spark may create an

electrical and/or fire hazard during maintenance.

Do not clean or service the spray gun with the

power supply On. Verify that the power supply

has been turned OFF to ground.

>

Unexpected robot movement can be hazard-

ous. Do not adjust or repair the spray gun when

the robot is operating or waiting to start. The

robot must be taken out of service.

>

Follow all Lockout/Tagout procedures prior

to entering to service the applicator, OSHA 29

CFR 1910.147.

W A R N I N G

!

It is always best if the gun is covered with a non-con-

ductive gun cover. This cover speeds up the cleaning

process of the exterior of the applicator. The covers

should be replaced as required. As the gun covers

fill with overspray material, they must be replaced

because they become a path to ground, lowering kV

ouput and increasing current draw.

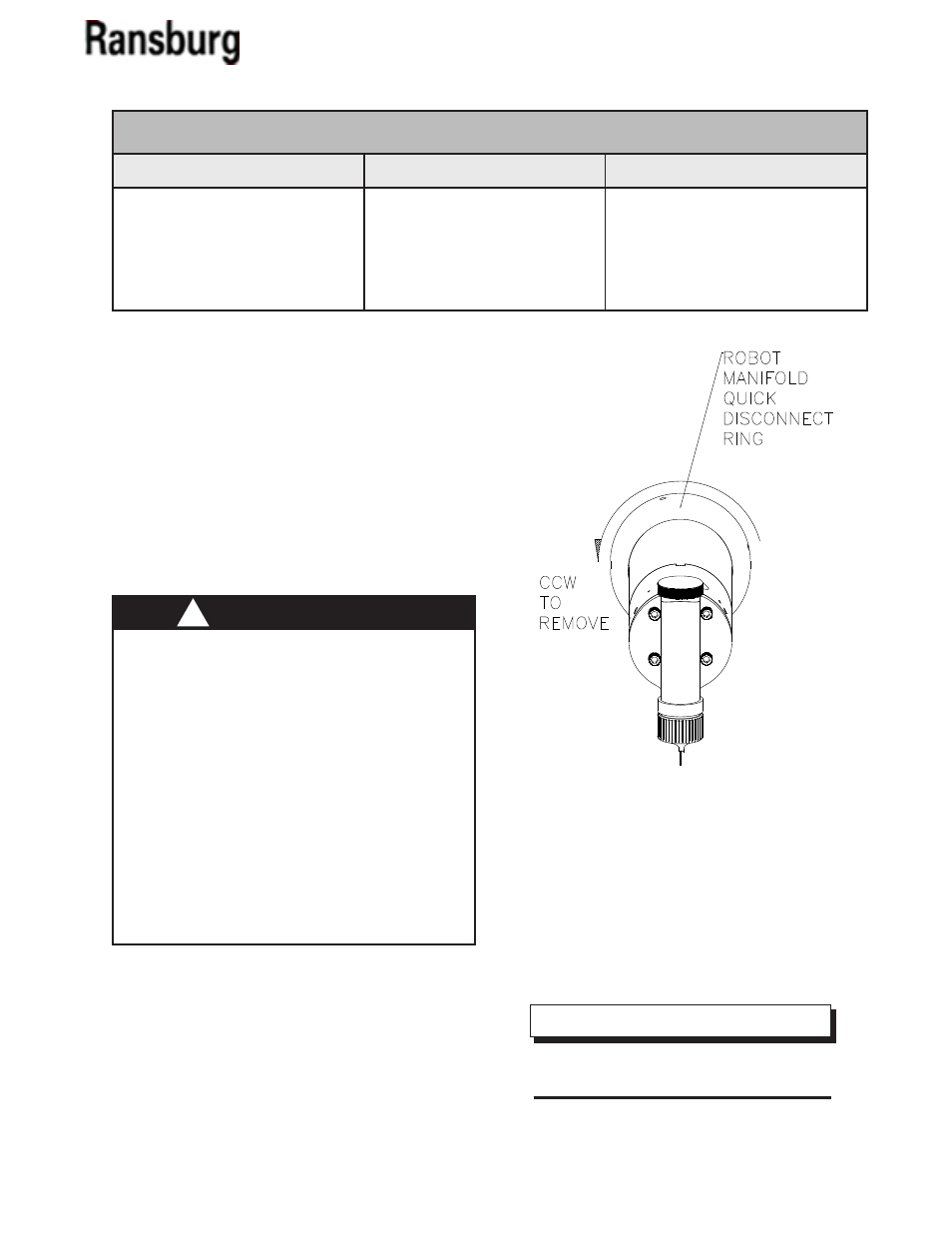

Applicator Disassembly

Figure 7: Removal of Applicator

2. Take applicator to a clean area outside the spray

area, preferably to a designated maintenance area.

3. Remove head retaining screws [4] as shown in

Figure 8 using a 1/4" wrench. This removes the head

from the manifold.

Head Removal/Repair

1. Relieve all pressures, flush out paint lines, and

blow all lines dry. Remove gun from robot by turning

the retaining ring counter clockwise from the robot

mount plate (See Figure 7.)

>

Be sure to contain all o-rings between

the head and manifold.

NOTE

AA-03-01.1