Robot waterbase applicator - maintenance, Fluid tube repair / replace, Fluid tube reassembly – Ransburg Evolver Water Applicator 78863-90, 78863-60 User Manual

Page 36

32

Robot Waterbase Applicator - Maintenance

Figure 12: Solvent Resistant O-Ring Kit

1. To remove and replace low voltage cable, refer

to Figure 18. Remove applicator from robot wrist.

(See Figure 7.)

2. Remove screw [1] from position shown. Insert

3/16" wrench to remove set screw [2]. The cable may

now be removed.

3. To re-install, pull the cable through the robot

arm. Install in the low voltage cable hole. Align the

timing marks as shown in Figure 19.

4. Tighten the set screw [2] until tight. Re-install

the screw into position shown.

Fluid Tube Repair / Replace

1. Remove the atomizer from the robot. (Refer to

Figure 7.)

8. Pull out the tube straight out of the fitting, being

carefull not to break the ferrules.

9. Carefully slide the ferrules and nuts off the old

fluid lines for re-use.

10. Cut the existing tube a minimum of 2 ft. back from

the end where the barbed fittings were located.

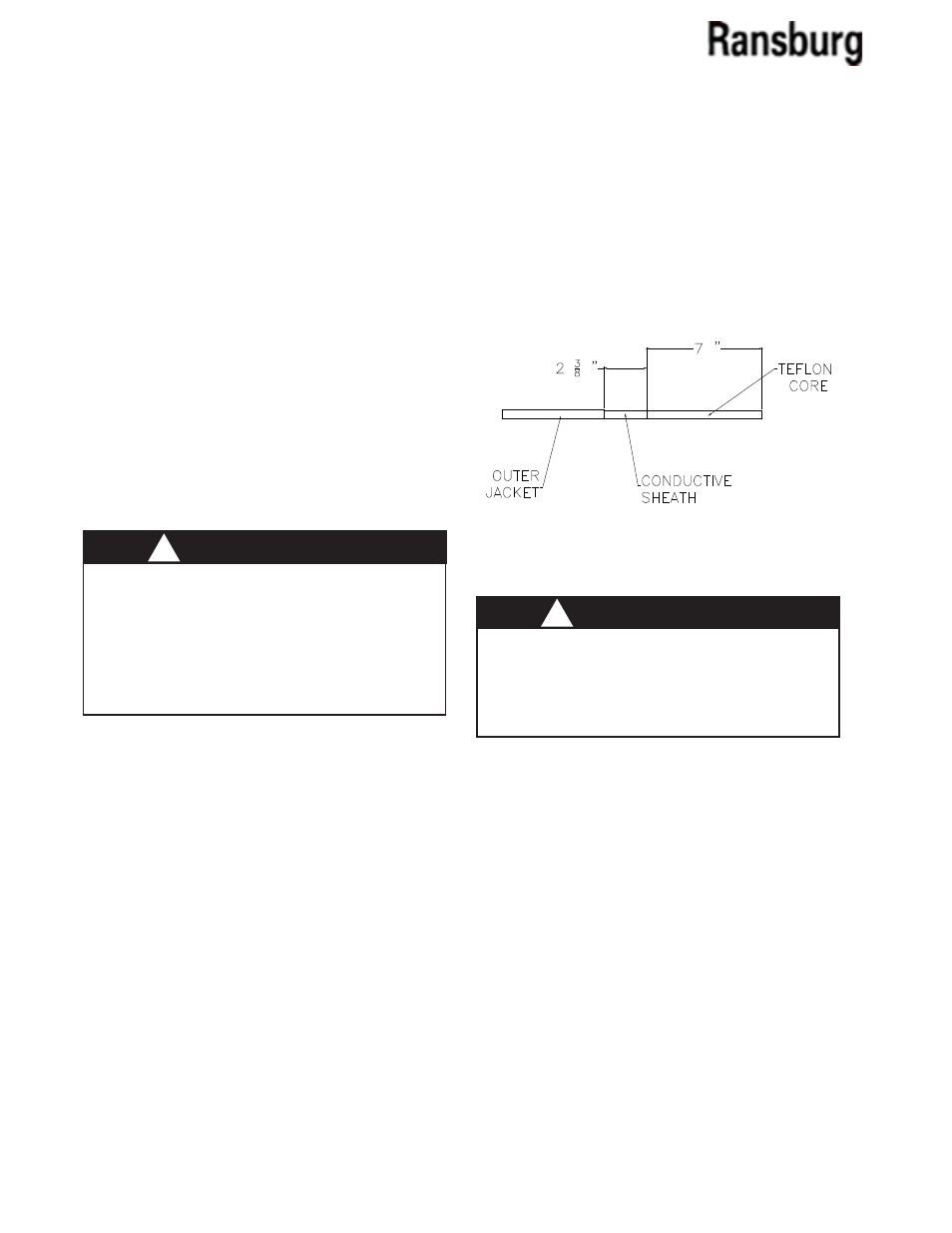

11. Cut away the jacket and coductive sheath ac-

cording to Figure 19.

>

If the inner of the fluid line is nicked in any

way, you must start over at Step 10. Any nicks

will cause premature failure or high voltage pin

holing after installation.

W A R N I N G

!

>

Depressurize, clean, and blow all fluid lines

dry.

>

Insure voltage is turned OFF.

>

Insure robot is locked-out.

W A R N I N G

!

2. Remove (6) screws that retain the tubing

bundle to the robot wrist.

3. Disconnect all cable and tubing connections.

4. Clamp the robot plate in a soft jawed vice to prevent

any scratching or defacing of the plate.

5. Remove all pilot lines around the fluid dump

line.

6. Remove the nut from the paint and dump line

fittings.

7. Cut off the end of the tube where the barbed

fittings are located and discard the barbed fittings

Figure 19: Fluid Hose Cutback Diagram

Fluid Tube Reassembly

12. Apply a thin film of SSL-11 petroleum jelly on the

conductive sheath to aid installlation of ferrule.

13. Slide nut over the tube. Carefully, slide the fer-

rule over the conductive sheath, leaving no raised

edges. Insure the outer jacket of the tube bottoms

out inside the ferrule.

14. Apply anti sieze to the fitting threads. Slide the

tube inside the fitting, until the ferrule shoulders

against the back of the fitting. Carefully slide the nut

over the ferrule and tighten.

AA-03-01.1