Electronics International CGR-30P User Manual

Page 51

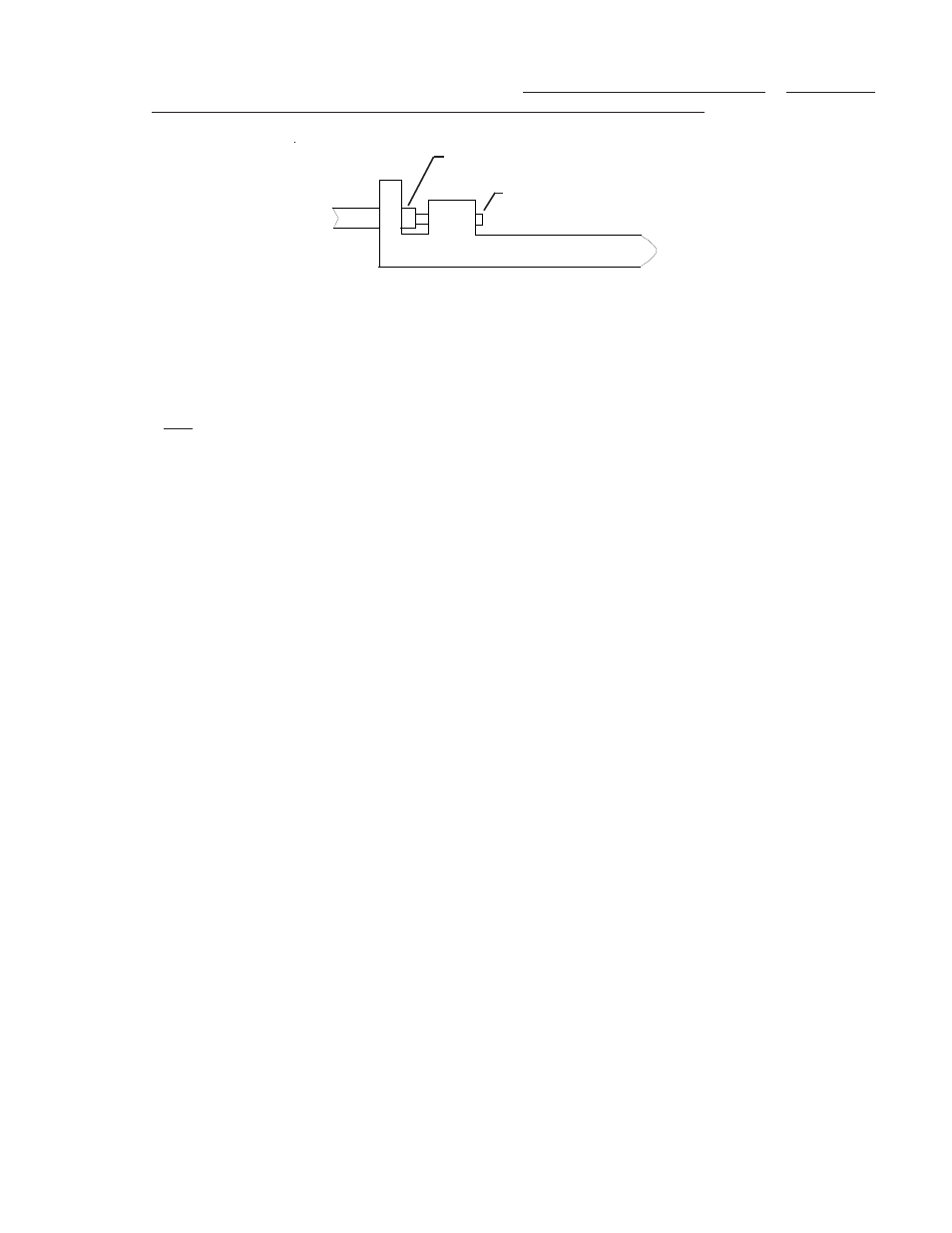

C. Insert the wire into the pin. Check that the insulation is in the strain relief crimp area but not in the bare

wire crimp area. Crimp the pin onto the wire. A good crimp is very important

A good crimp is very important

A good crimp is very important

A good crimp is very important

A good crimp is very important.

.

.

.

. Poor crimps

Poor crimps

Poor crimps

Poor crimps

Poor crimps

will cause jumpy readings and are the biggest source of problems

will cause jumpy readings and are the biggest source of problems

will cause jumpy readings and are the biggest source of problems

will cause jumpy readings and are the biggest source of problems

will cause jumpy readings and are the biggest source of problems.....

4 2

Insulation

E.I. D-sub Pin

Bare Wire

D. Pull Test: Pull (approximately 3 to 4 pounds) on the wire near the connector with one hand while

holding the connector with the other hand. If the wire pulls out of the connector, you must start over

using a new connector.

E. A well soldered connection at the crimp can be reliable. Soldering a TC wire requires a lot of heat to

produce a good solder connection. Also, when soldering a TC wire each wire should be scraped with

a knife to expose fresh metal just before crimping and applying solder. Fluxing the TC wire can also

help. Do not use acid core solder or acid flux.