1 instructions for continued airworthiness (ica), 2 airworthiness limitations – Electronics International CGR-30P User Manual

Page 50

6.1 Instructions for Continued Airworthiness (ICA):

The Instructions for Continued Airworthiness (ICA) are located in the Electronics International document

06211301 "CGR-30P Instructions for Continued Airworthiness". If you need an additional copy of the CGR-

30P ICA please visit: www.Buy-Ei.com or call (541) 318-6060.

6.2 Airworthiness Limitations:

The Airworthiness Limitations section is FAA approved and specifies maintenance required under CFR 43.16 and

91.403 of the Code of Federal Aviation Regulations unless an alternative program has been FAA approved.

Operational:

The conditions and tests required for TSO approval of the CGR-30 are minimum performance stan-

dards. It is the responsibility of those installing this system either on or within a specific type or class

of aircraft to determine that the aircraft installation conditions are within the TSO standards. TSO

articles must have separate approval for installation in an aircraft. The CGR-30 may be installed only

if performed under 14 CFR part 43 or the applicable airworthiness requirements. There are no further

specific operating limitations of this system.

Installation:

The CGR-30 system is to be installed in accordance with the current CGR-30 Installation Instructions,

AC 43.13 and any other appropriate FAA approved practices or guidelines. These instructions along

with FAA approved material insure the system will meet the requirements of the applicable TSOs

once installed in an aircraft. There are no further specific installation limitations of this system.

6.3 Installing a D-sub Pin onto a TC or Tin Copper Wire:

D-sub pins are used in D-sub connectors found on the EDC and the CGR. Most of these pins have already been

installed on the appropriate wires and inserted into the proper connector. To install a D-sub pin requires a D-sub

crimp tool. Most electronic stores carry a reasonably priced D-sub crimp tool. This tool will work for installing D-

sub pins onto tin copper wire but it may not make good crimps on 24 ga. thermocouple wire. A pull test can be

performed to test the crimp. A ratcheting crimp tool from Tyco (P/N: 91503-1) will crimp both TC and Tin Cop-

per Wire. All crimps must pass a 3 to 4 pound pull test to be considered reliable. To install a D-sub pin onto a 20

ga. Tin Copper Wire, perform the following steps:

A. Strip the insulation back 1/8.” Be careful not to knick the wire.

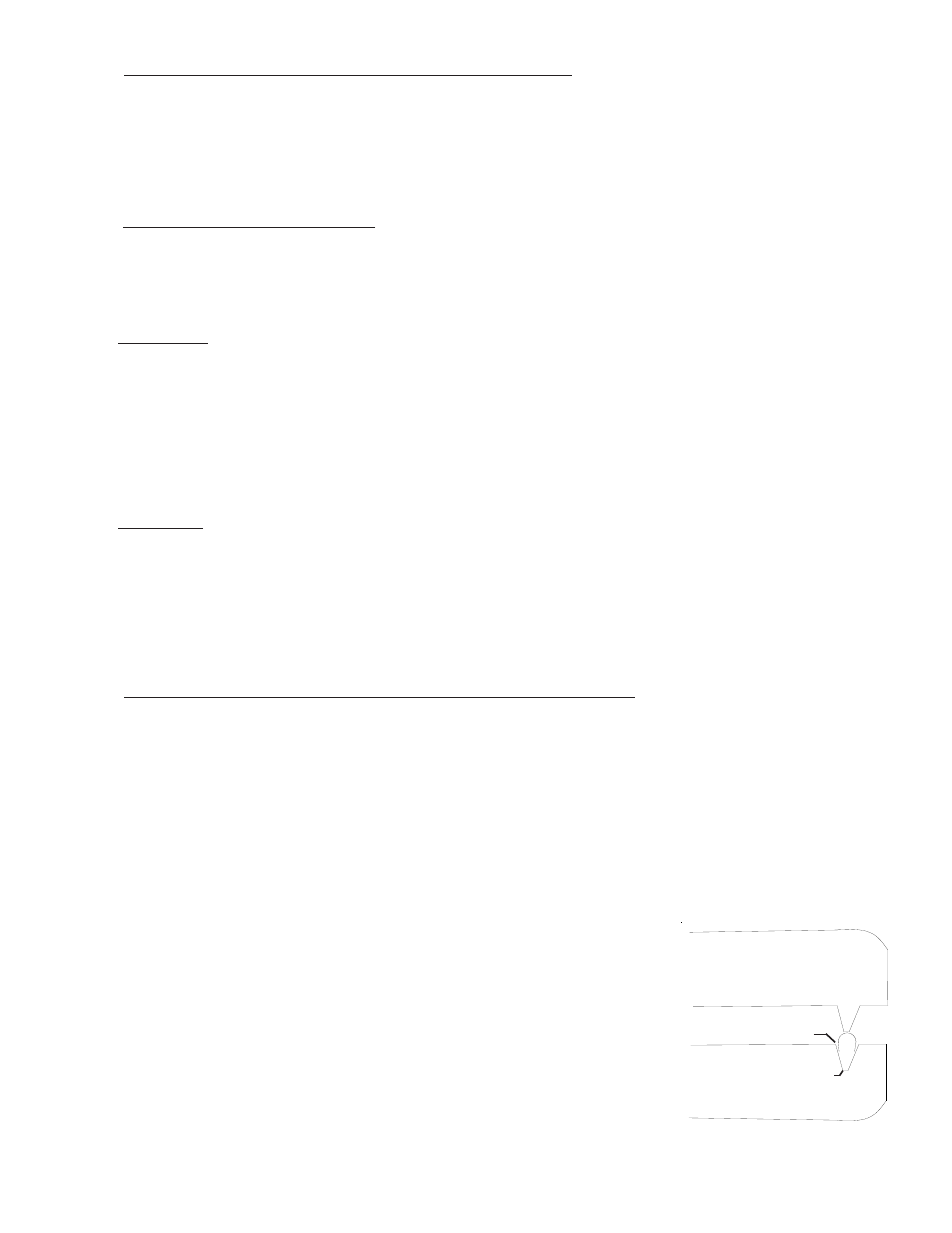

B. Insert the pin into the 24 ga. D-sub Pin Crimper. The crimpers have

two cavities; the smaller one is used to crimp the bare wire and the

slightly larger one is used to crimp around the insulation. Check that

the pin is inserted into the crimpers properly. Also, the ears on the pin

must be facing into the center of the crimp tool cavity to produce a

good crimp. If the pin rotates even a little during crimping, the

connection will be unreliable.

4 1

Crimp Cavity

Pin Ears face Down

End View

of

the D-sub Pin in the Crimp Tool