System design considerations – Liquid Controls MS Meters User Manual

Page 7

7

Strainer/Air

Eliminator

Supply Side

Isolation Valve

MS Series Meter

Outlet Side

Isolation Valve

Pulse Output

Device (POD)

System Design Considerations

Flowmeters must be installed properly if accuracy and

repeatability of measurements are to be sustained over

long periods of time. The system in which the meters

are to be used must have provisions for controlling flow,

transitional, and no flow conditions. Pressure, both

hydrostatic and hydrodynamic, must be an integral part

of the variables controlled in the flowing system. Systems

in which meters are to be installed must be designed to

eliminate transient pressure conditions, eliminate

thermally induced pressure increases, and to exclude

air or vapor.

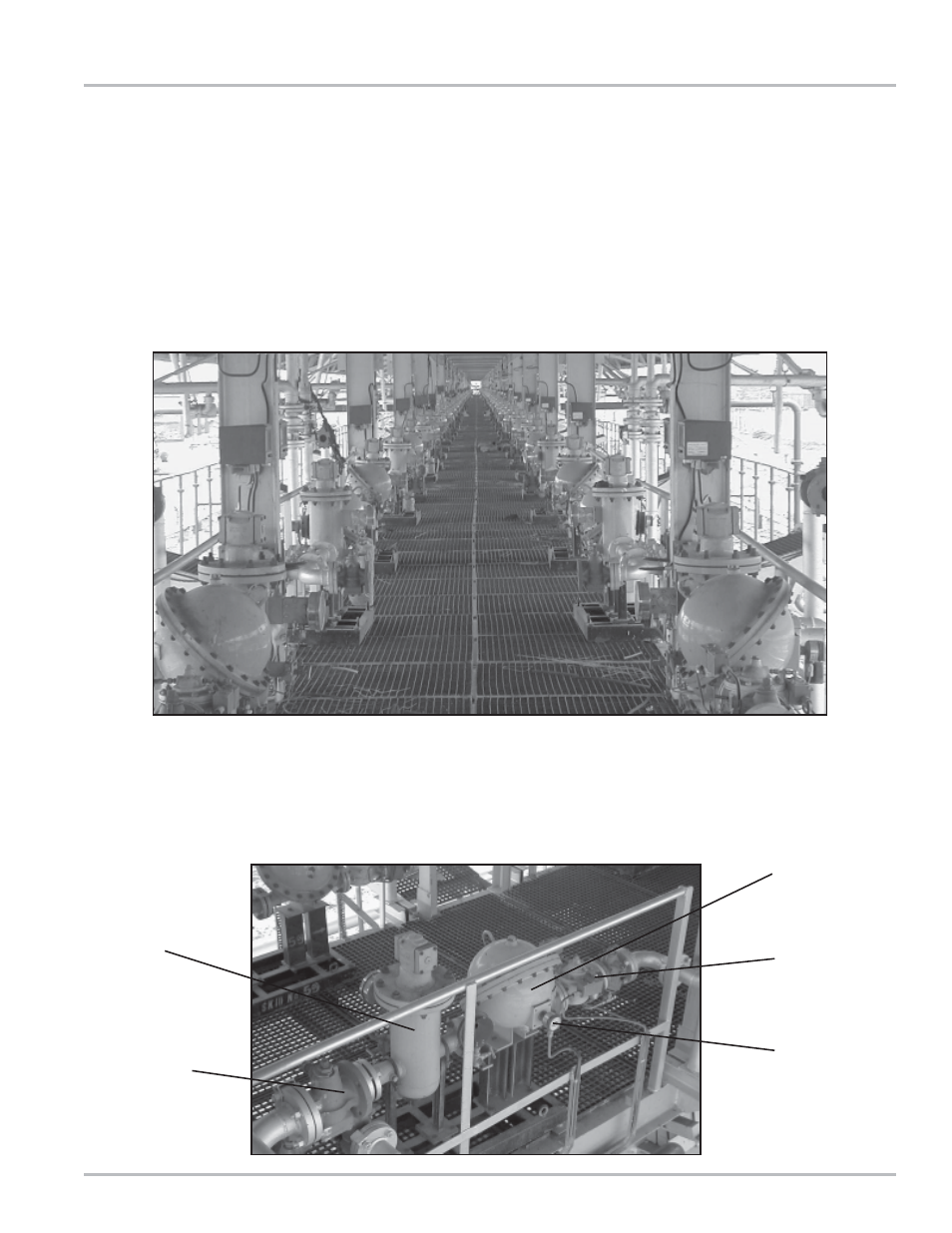

The next photograph shows a typical gantry position.

From left to right, there is a supply line attached to an

isolation valve, a second isolation valve and piping

leading vertically to the loading arm. The meter is

equipped with a dual channel, quadrature pulse

The complete system must be kept full of product at all

times. The photograph below is a typical fuel delivery

gantry designed for loading rail tank wagons. This

particular gantry has provisions for loading 152 rail tank

wagons at one time. Four different fuels are supplied to

the gantry through 16 inch pipe lines which are

approximately ½ mile long. The pumps are centrifugal

type and are located between 100 and 300 yards from

the storage tanks.

transmitter connected directly to a batch controller. The

batch controller provides preset batch capability, flow rate

control, and slow flow start and stop. There is one batch

controller for each metering position.