Disassembling the meter, Warning – Liquid Controls MS Meters User Manual

Page 21

21

Disassembling the Meter

(See Pages 31 & 32 for the Torque and Wrench & Socket Size Charts)

!

!

!

!

!

WARNING

All internal pressures must be relieved before disassembly of the meter, strainer, vapor eliminator,

any valves in the system, the pulse output device, or the front and rear covers. LINE PRESSURE

MUST BE 0.0 PSI. See “Meter Maintenance” on Page 15 for the procedures to relieve internal

pressure.

1.

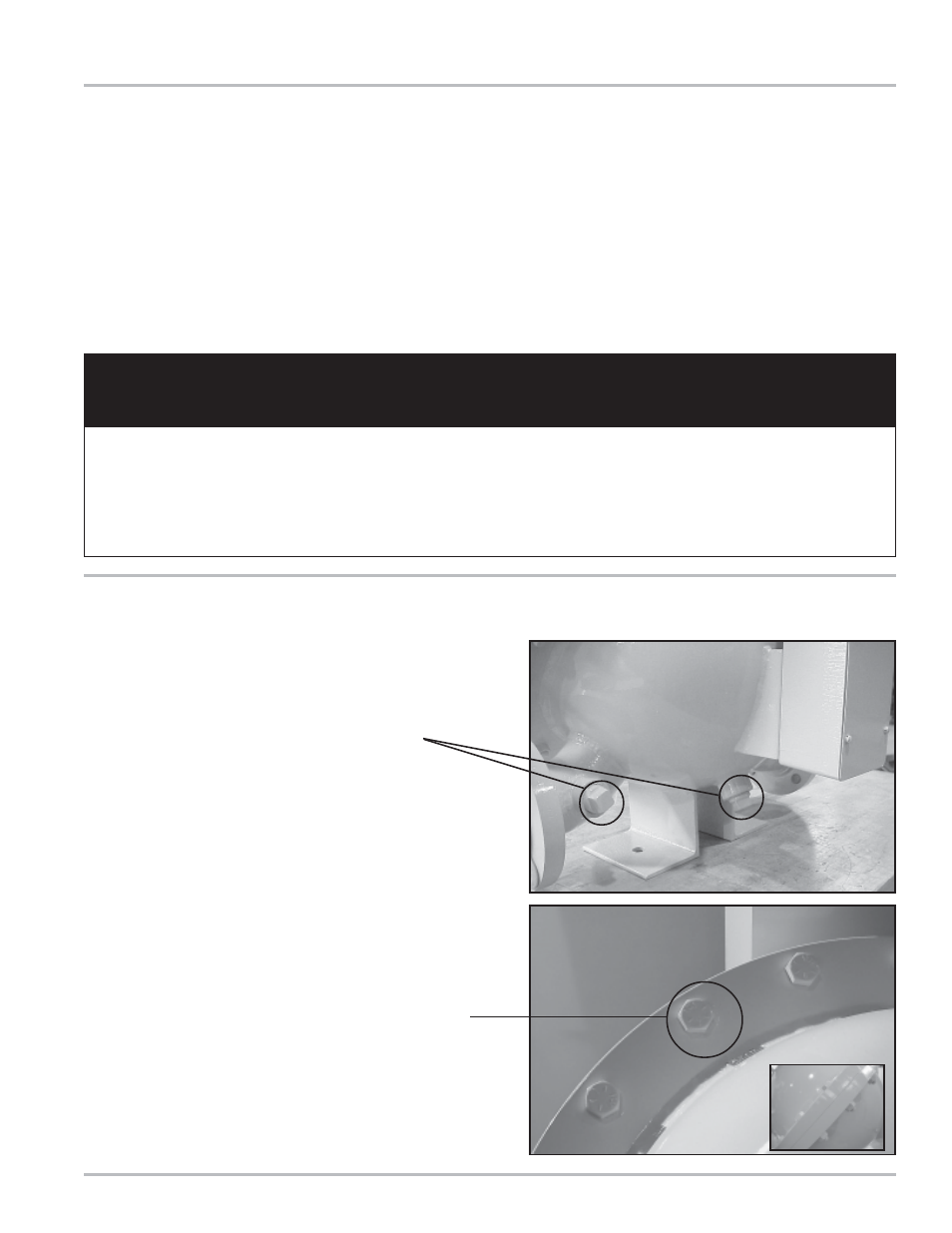

After the internal pressure has be relieved, open the

drain plugs located at the bottom of the weldment

assembly and discharge arm to drain all fluid from

the weldment assembly.

Draining Fluid from the Meter

2.

Once the system has been completely drained, the

weldment assembly may be opened by removing the

cover screws and bolts that are located around the

rim of the enclosure.

The number of bolts may vary between the different

meter sizes.

Opening the Weldment Assembly

Tools:

Torque Chart

Wrench & Socket Size Chart

Counter bracket wrench or socket

Drain plug wrench

Cover socket or open end/box end wrench

Standard screwdrivers (2)

Spare displacement rotor gear

Bearing plate wrench

Plastic or rubber mallet

Emery cloth

Wire brush