Wrench and socket size chart, Bolt tightening sequence – Liquid Controls MS Meters User Manual

Page 31

31

Dust

Cover

Screws

Counter

Bracket

Screws

Bearing

Plate

Screws

Rotor

Gear

Screws

Element

Mounting

Bolts

Drain

Plug

Cover

Vent

Plug

Weldment

Cover

MS-7

MSB-7

slotted

screwdriver

1/4" Allen

wrench

7/16" wrench/

socket

3/8" wrench/

socket

1/4" Allen

wrench

13/16" 4-point

socket

9/16 4-point

socket

3/4" wrench/

socket

MSA-7

MSAA-7

slotted

screwdriver

1/4" Allen

wrench

7/16" wrench/

socket

3/8" wrench/

socket

1/4" Allen

wrench

13/16" 4-point

socket

9/16 4-point

socket

9/16" wrench/

socket

MSC-7

slotted

screwdriver

1/4" Allen

wrench

7/16" wrench/

socket

3/8" wrench/

socket

1/4" Allen

wrench

13/16" 4-point

socket

9/16 4-point

socket

15/16" wrench/

socket

MS-15

MSA-15

MSAA-15

slotted

screwdriver

1/4" Allen

wrench

7/16" wrench/

socket

3/16" Allen

wrench

1/4" Allen

wrench

13/16" 4-point

socket

13/16" 4-point

socket

9/16" wrench/

socket

MSB-15

MSC-15

slotted

screwdriver

1/4" Allen

wrench

7/16" wrench/

socket

3/16" Allen

wrench

1/4" Allen

wrench

13/16" 4-point

socket

13/16" 4-point

socket

1-5/16" wrench/

socket

MS-30

MSA-30

MSAA-30

MS-40

slotted

screwdriver

1/4" Allen

wrench

7/16" wrench/

socket

3/16" Allen

wrench

9/16" wrench/

socket

13/16" 4-point

socket

13/16" 4-point

socket

3/4" wrench/

socket

MSB-30

MSC-30

slotted

screwdriver

1/4" Allen

wrench

7/16" wrench/

socket

3/16" Allen

wrench

9/16" wrench/

socket

13/16" 4-point

socket

13/16" 4-point

socket

1-5/8 wrench/

socket

MS-75

MSA-75

MSAA-75

MSB-75

MSC-75

slotted

screwdriver

1/4" Allen

wrench

1/2" wrench/

socket

9/16" wrench/

socket

15/16" wrench/

socket

13/16" 4-point

socket

13/16" 4-point

socket

15/16" wrench/

socket

MS-120

MSA-120

MSAA-120

slotted

screwdriver

1/4" Allen

wrench

1/2" wrench/

socket

9/16" wrench/

socket

15/16" wrench/

socket

13/16" 4-point

socket

13/16" 4-point

socket

1-1/8" wrench/

socket

WRENCH/SOCKET USED

Meter Element

Weldment Assembly

Meter

Model

Wrench and Socket Size Chart

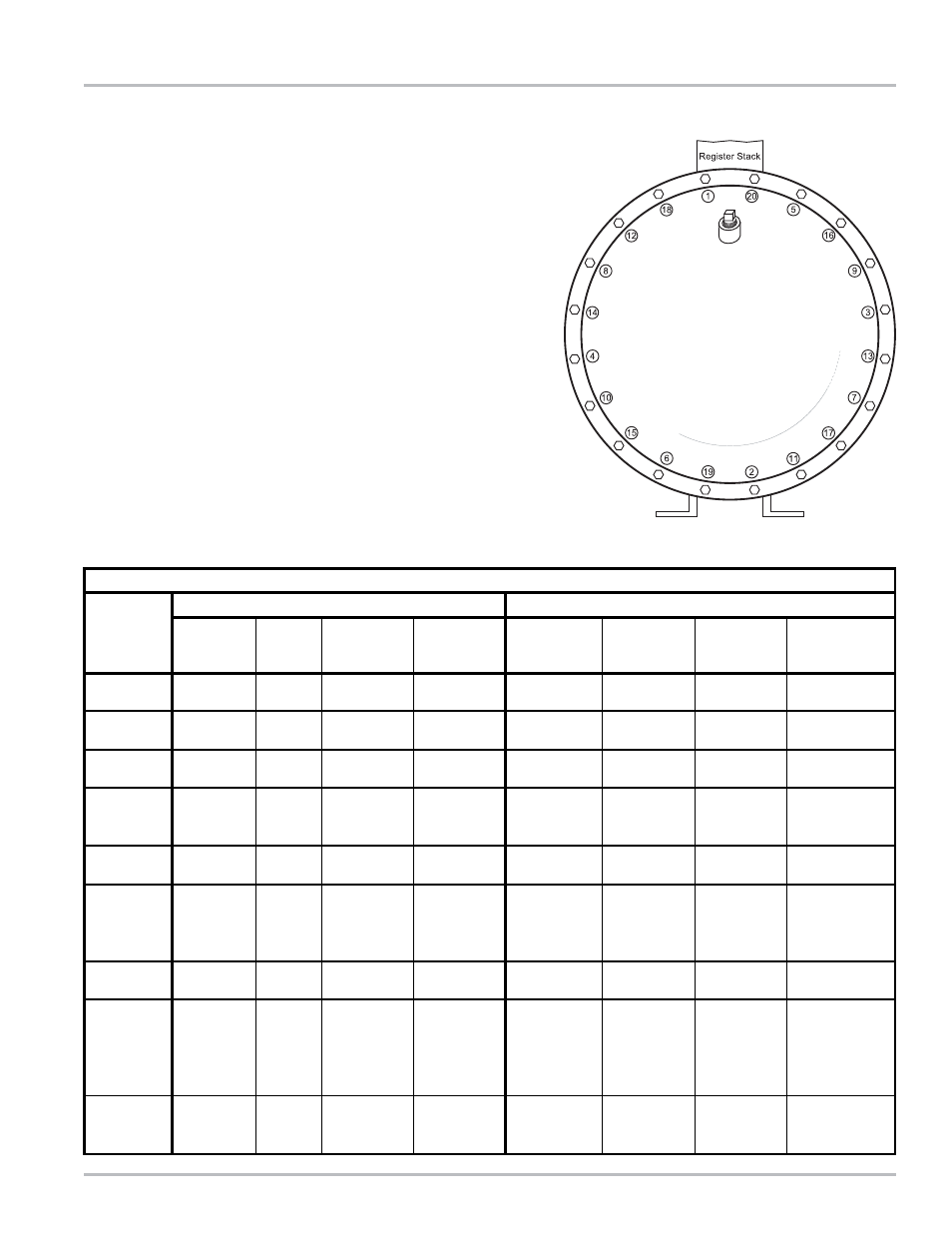

Bolt Tightening Sequence

When placing the weldment cover on the weldment base,

it is important that the bolts are tightened in a sequence

which reduces the risk of leaking when the system is put

back in service. The number of bolts will vary depending

on the size of the meter. The general pattern should be

followed as pictured.

It is important to ensure that the O-Ring does not get

pinched during this process.

Tighten the bolts following the pattern to 50% of the

nominal torque. When all the bolts are torqued to 50%,

they should then be torqued to the proper setting following

the same pattern. Follow the torque specifications listed.

When replacing fastener elements, it is recommended

to use compatible components.