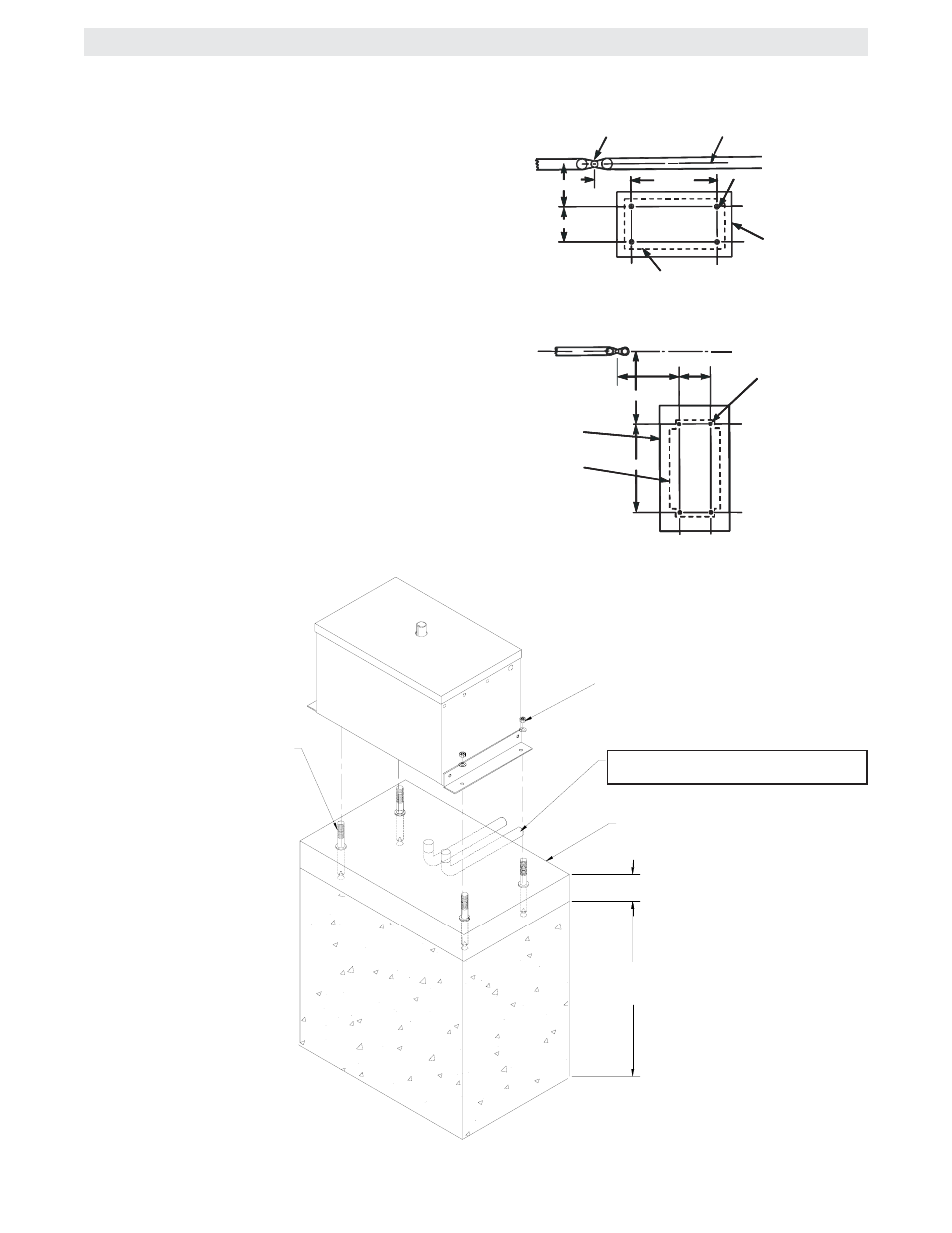

Pad mounting (sw470), Figure 2, Figure 1 figure 2 – Controlled Products Systems Group SW4705011G3 User Manual

Page 9

9

1/2" RED HEAD BOLTS

0R ANCHORS (4 REQUIRED)

2" TO 4"

ABOVE GRADE

DEPTH REQUIRED

BY LOCAL CODES OR

BELOW FROST LINE

POWER AND CONTROL WIRING

SHOULD BE RUN IN SEPERATE CONDUIT

CONCRETE

PAD

USING SUITABLE

HARDWARE SECURE

OPERATOR TO L-BOLTS

PAD MOUNTING (SW470)

NOTE: For the following instructions refer to figures 1

& 2.

1. Layout the concrete pad as detailed in figure 1.

IMPORTANT NOTE: The relative location of the oper-

ator to the fence and the gate is critical. Be sure that

the measurements for operator mounting are taken

from the centerline of the fence and of the gate hinge.

2. Locate electrical conduit, as required, prior to pour-

ing concrete.

3. Pour concrete pad.

4. Bolt the (2) pad mount brackets to the bottom of

the operator with the hardware provided.

5. Secure the operator to the pad. It is very impor-

tant that the operator be level and square to the gate.

GATE

CONCRETE PAD

18" X 34" MIN.

PROFILE OF

OPERATOR

SW470

PERPENDICULAR

CENTERLINE

1/2" REDHEAD

(4 REQ'D)

16"

8"

18-3/4"

22-1/2"

HINGE PIN

FENCE

9-3/4"

22-1/2"

24"

C

L

8"

1/2" REDHEAD

(4 REQ'D.)

CONCRETE PAD

18" X 34" MIN.

OPERATOR

PARALLEL MOUNT

PERPENDICULAR MOUNT

FIGURE 1

FIGURE 2