Controller programming and features, Motor learn button, Force control – Controlled Products Systems Group SW4705011G3 User Manual

Page 21

21

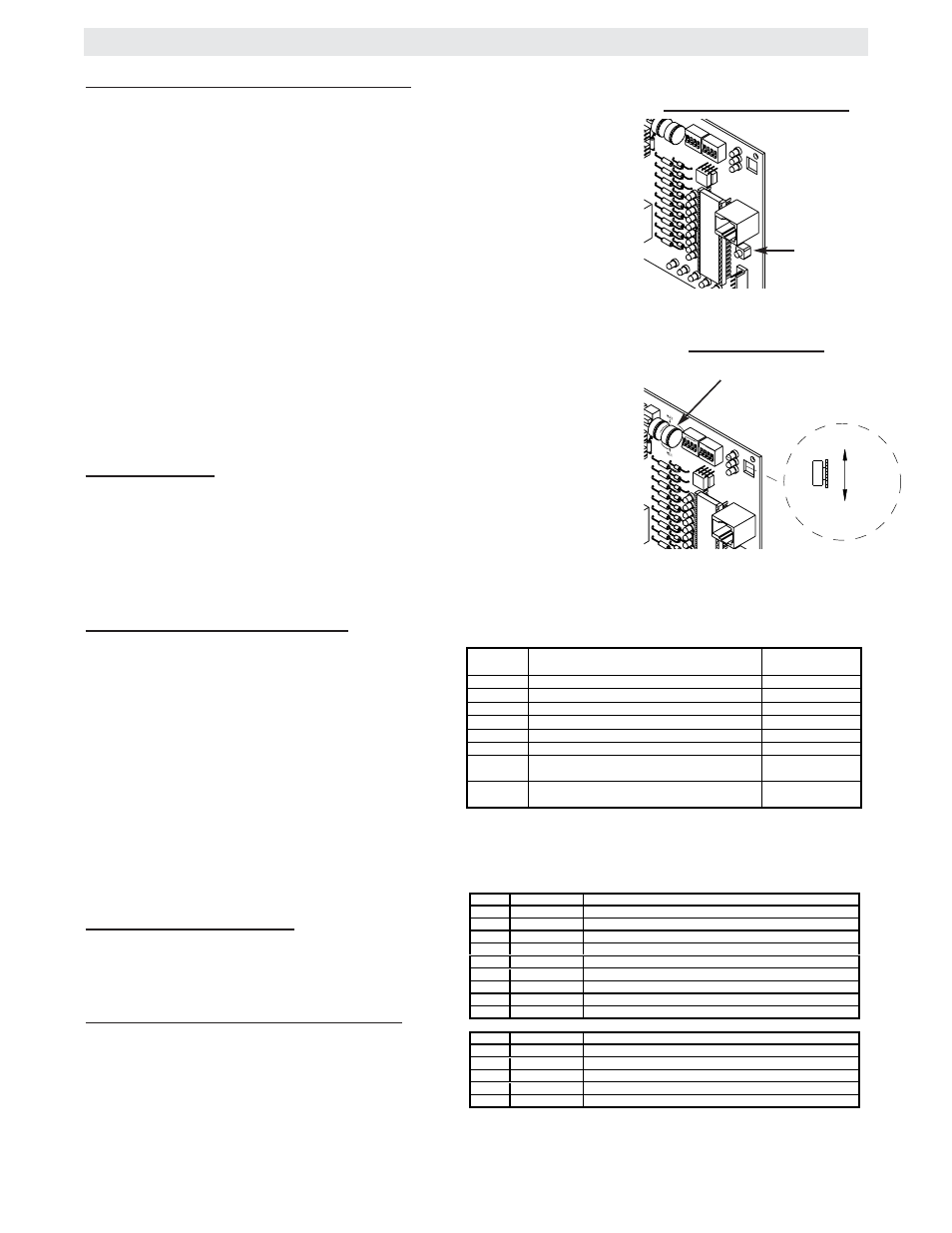

MOTOR LEARN FUNCTION (FORCE PROFILE)

This function is preprogrammed at factory. If either board or motor is replaced, the

controller will need to be programmed to “LEARN” the specific motor RPM profile

only of your operator. Switch “S3” is provided for this. This is important for accu-

rate force control. Failure to do so may result in improper and unsafe operation.

To learn the motor:

NOTE: Motor Learn must be performed in stand along mode.

1. Detach the unit from the gate, the motor needs to be learned without a load.

2. Press the motor learn button. The yellow LED should start to flash rapidly.

3. Install a jumper on either the hard open or the hard close input terminals. The

motor will run for a few seconds and then stop. If the LED goes out the motor is

learned. If the unit activates a limit before completing the learn or some other error

occurs the LED will go back to on continuously. If this happens try learning while

running in the opposite direction.

NOTE: It is important that the jumper is in constant contact while the gate is

moving in learn mode.

4. Reconnect the unit to the gate, reset the limits and adjust the force control.

FORCE CONTROL

Set the force control pot such that the unit will complete a full cycle of gate travel

but can be reversed off an obstruction without applying an unreasonable amount of

force. On most operators this will be around the middle of the range.

CONTROLLER PROGRAMMING AND FEATURES

DIAGNOSTICS (LEDS AND CODES)

There are three diagnostic LEDs. Two red LEDs

(OL, CL) are indicators for the open and close limits.

The LEDs are illuminated when the limit switch con-

tacts are closed.

The third amber LED (DIA) is used to blink out diag-

nostic codes. The number is the count of the num-

ber of times the LED is on in an 8 second period.

The LED is on for approximately 1/2 second and

repeats every second until the number is reached.

There will be a pause following each pulse cycle (1-

6 pulses) to differentiate between the different diag-

nostic codes.

TROUBLESHOOTING LED’S

There are 9 troubleshooting LEDs (D11, D13, D15,

D17, D19, D21, D24, D29, D31).

RELAY DRIVE TROUBLESHOOTING LED’S

There are 5 troubleshooting LEDs (D2, D3, D4, D5,

D6) on relay drives K1 through K5. These LEDs will

be illuminated when the microcontroller relay drive

is activated.

LED CODE

FLASHED

DIAGNOSTIC

MEANING

CLEARED BY

OFF

Normal operation.

N/A

1

Single entrapment sense.

Control Input

2

Double entrapment sense.

Hard Input*

3

Failed or no hall effect sensor.

Removal of problem.

4

Exceed maximum motor run time.

Hard Input*

5

Limit fault.

Control Input*

6

Loss of communications between master and

second during run mode.

Removal of problem.

ON

NO FLASH

Motor not learned.

Completion of motor

Learn Routine

LED NAME

LED

DESCRIPTION

RADIO

On when radio switch activated.

SHADOW

On when shadow loop is activated.

HARD CLOSE

On when hard close switch is activated.

STOP

On when stop switch is not activated.

SOFT OPEN

On when soft open switch is activated.

HARD OPEN

On when hard open switch is activated.

INT. LOOP

On when interrupt/safety loop activated.

OBS. OPEN

On when edge is activated or when photo eye beam is broken.

OBS. CLOSE

D11

D13

D15

D17

D19

D21

D24

D29

D31

On when edge is activated or when photo eye beam is broken.

LED NAME

LED

DESCRIPTION

CONT A

On when CONTACTOR A activated.

CONT B

On when CONTACTOR B activated.

SAM

On when Sam Relay is activated.

LOCK

On when Mag Lock Relay is activated.

ALARM

D6

D5

D4

D3

D2

On when Alarm Relay is activated.

MOTOR LEARN BUTTON

MOTOR

LEARN

BUTTON

LESS

MORE

SENSITIVITY

FORCE CONTROL

FORCE

ADJUSTMENT

* HARD INPUTS INCLUDE HARD OPEN, CLOSE AND

STOP INPUTS.

NOTE: For LED location refer to illustration on previous page.