Control arm assembly (sw490), Figure 2, Figure 1 – Controlled Products Systems Group SW4705011G3 User Manual

Page 12: Figure 3, Figure 4

3/4”-10 x 3 HEX HEAD BOLT

3/4” FLAT WASHER

3/4” BUSHING

EXTENSION ARM

HOLDER

GATE BRACKET

OR

EXTENSION ARM

3/4” FLAT WASHER

3/4” FLAT WASHER

3/4” SPLIT LOCK WASHER

3/4”-10 HEX NUT

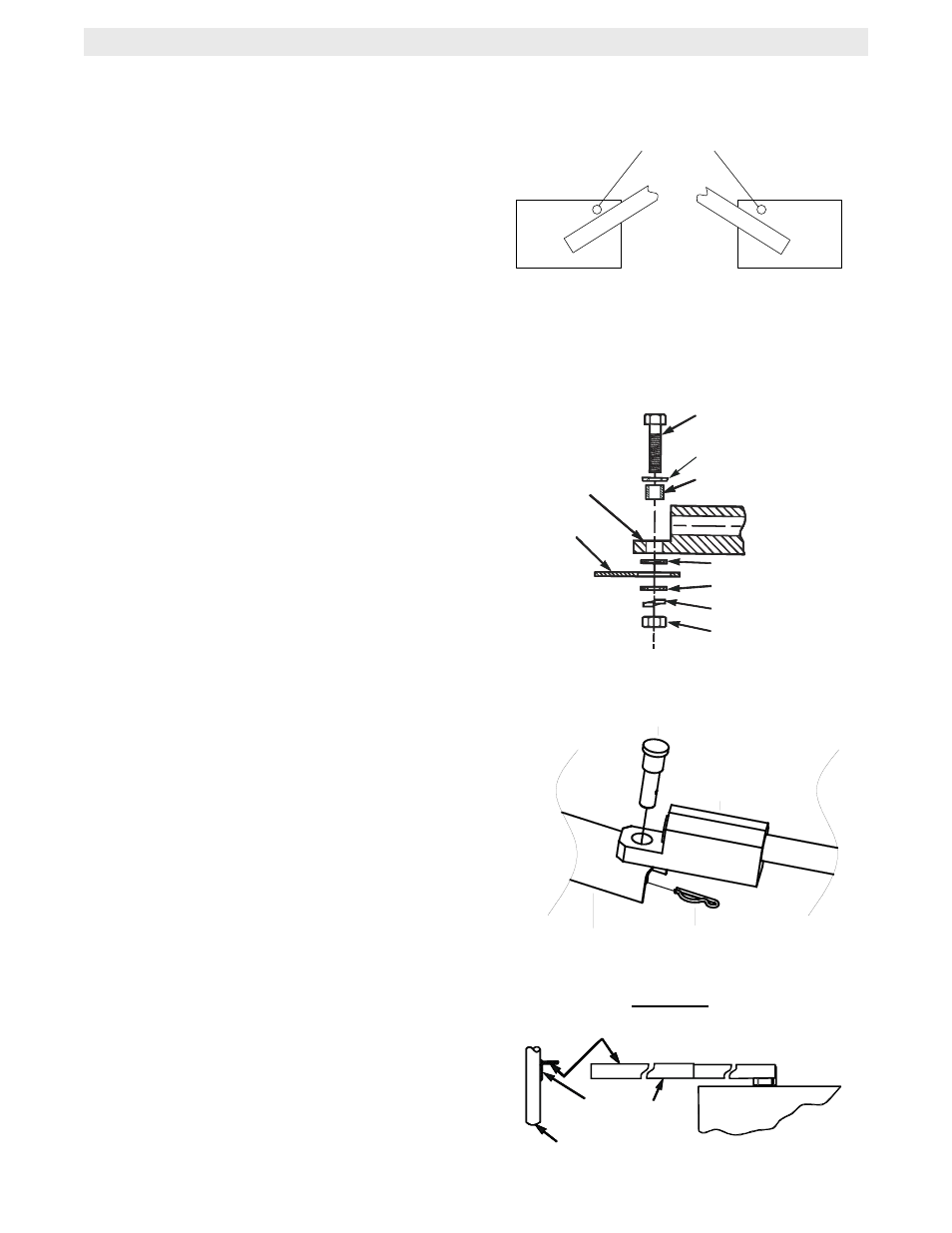

FIGURE 2

12

CONTROL ARM ASSEMBLY (SW490)

RIGHT HAND

INSTALLATION

SW490 PARALLEL

TO FENCE

LEFT HAND

INSTALLATION

CLOSE STOPS

FIGURE 1

1. Set the control arm’s close stop on the operator so

that it’s position corresponds with the handling of the

installation. (See figure 1)

2. Remove the open stop, as it is not to be used in this

application. Use any existing hardware necessary to

seal the open stop’s hole in the operator’s cover.

3. Measure the length of the gate panel and select the

appropriate extension arm (x) and control arm (Y)

dimensions from the gate installation table.

4. Install the control arm hub assembly to the opera-

tor’s output shaft. Make sure that the key is properly

inserted into the hub assemblies keyway. Lock the key

in place with using the set screw provided in the hub.

5. Attach control arm extension to control arm hub

assembly by bolting or welding the two pieces together

to achieve the proper control arm dimension (Y).

6. Determine the proper location of the gate bracket by

measuring the gate panel’s length and referring to the

gate installation table (Dimension B) on the next page.

Install the supplied gate bracket or install your own gate

bracket (recommended 2” x 2” x 1/4” angle) horizontal-

ly on the gate and at the same height as the top surface

of the control arm extension. Secure the gate bracket

to the gate by either welding or bolting the bracket to

the gate.

7. Assemble one extension arm holder to the gate

bracket using supplied hardware. (See figure 2)

8. Assemble the other extension arm holder to the con-

trol arm extension using the supplied pivot pin assem-

bly and cotter pin. (See figure 3)

9. Measure and cut pipe (not provided) and position

the pipe into the extension arm holders to achieve the

proper extension arm dimension (X). Insert the hex

head set screws in each extension arm holder in order

to hold pipe firmly. Do not tighten until testing and all

final adjustment have been completed.

COTTER PIN

EXTENSION ARM

PIVOT PIN

ASSEMBLY

EXTENSION ARM

HOLDER

FIGURE 3

BOTTOM OF ANGLE AND TOP OF CONTROL

ARM EXTENSION SHOULD BE LEVEL

2"x2"x1/4"

ANGLE (BY

OTHERS)

GATE

CONTROL ARM

EXTENSION

MODEL SW490

FIGURE 4