Auto-close timer dry relay contact leds, Inherent reverse sensor caution, Self-test – Controlled Products Systems Group 9050-080 User Manual

Page 22: Dip-switches, Magnetic sensors, Loop detector

9050-065-M-3-11

20

L1

NC

NO

SELF

TEST

TIME

DELAY

REV

SENS

REVERSE LOOP

EXIT LOOP

1

ON

2

3

4

5

6

7

8

12

11

10

9

8

7

6

5

4

3

2

1

9410

L1

9410

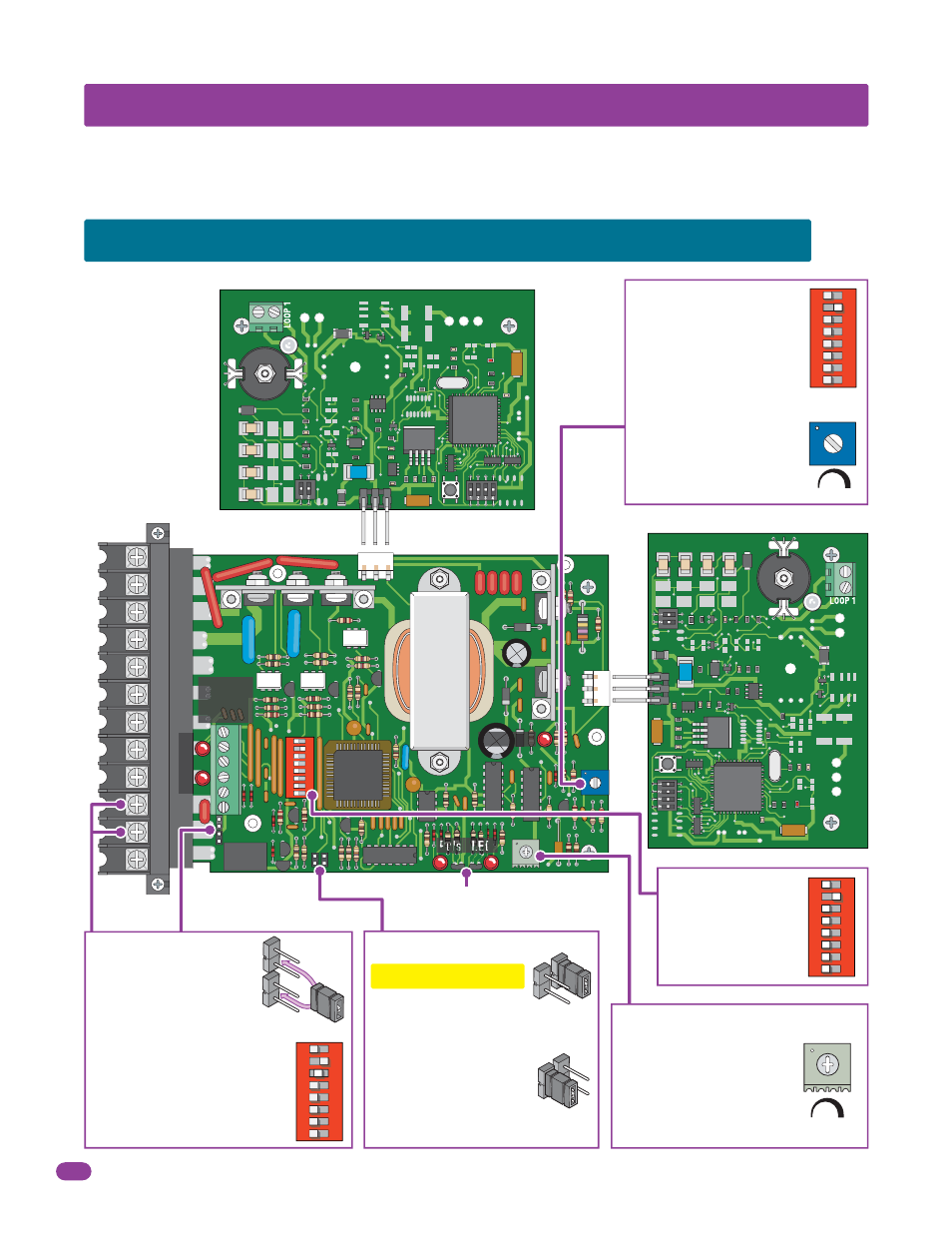

3.1 4702 Circuit Board Description and Adjustments

SECTION 3 - ADJUSTMENTS

The switch settings and adjustments in this chapter should be made after your installation and wiring to the operator(s) is

complete. Whenever any of the programming switches on the circuit board are changed, power must be shut-off, and then

turned back on for the new setting to take effect. Every time the operator is powered up, the First open command will

automatically run “Multiple gate cycles” that will locate and remember the gate’s open and close positions (See page 22).

Auto-close timer (when

turned ON) Switch 2.

Adjust from 1 second

(full counter clockwise) to

approximately 23 seconds

(full clockwise).

Auto-Close Timer

Dry Relay Contact

LEDs

Indicates that

low voltage power is

applied to the circuit

board. Input LEDs

should be OFF and

will only illuminate

when the input is

activated. Pulse

LEDs will blink as

the operator is

running. They can be

either ON or OFF

when the operator is

stopped.

Adjust reversing sensitivity.

Full counter clockwise for

minimum sensitivity, full

clockwise for maximum

sensitivity. See page 23.

Min

Max

Sensitivity

Inherent Reverse Sensor

CAUTION

Do not run self-test with

the operator connected to

the gate. The drive chain

must be disconnected

before running the

self-test. This feature is

designed for bench

testing ONLY.

Self-Test

UL 325

Terminal

Page 24

Power LED

Pulse LEDs

Input LEDs

Magnetic Sensors

See section 3.4 on page 23.

Loop Detector

See page 27.

Exit Loop Port

Reverse Loop Por

t

Loop Detector

See page 27.

Single Channel

Single Channel

1

23

Self-Test

Mode

Normal

Mode

See switch setting

chart on next page for

DIP-Switch options.

DIP-Switches

Typical setting shown.

NC

NO

1

ON

2

3

4

5

6

7

8

1

ON

2

3

4

5

6

7

8

1

ON

2

3

4

5

6

7

8

Dry relay contacts

(terminals 10-11)

can be set for Normally Open (NO) or

Normally Closed (NC) operation

by placing the relay shorting bar

on the N.O. or N.C. pins

respectively. DIP-switch 3 must

be set to control relay.

See next page and page 28.

TIME

DELAY