4 mounting actuator arm – Controlled Products Systems Group 6002-080 User Manual

Page 14

12

6002-065-M-6-08

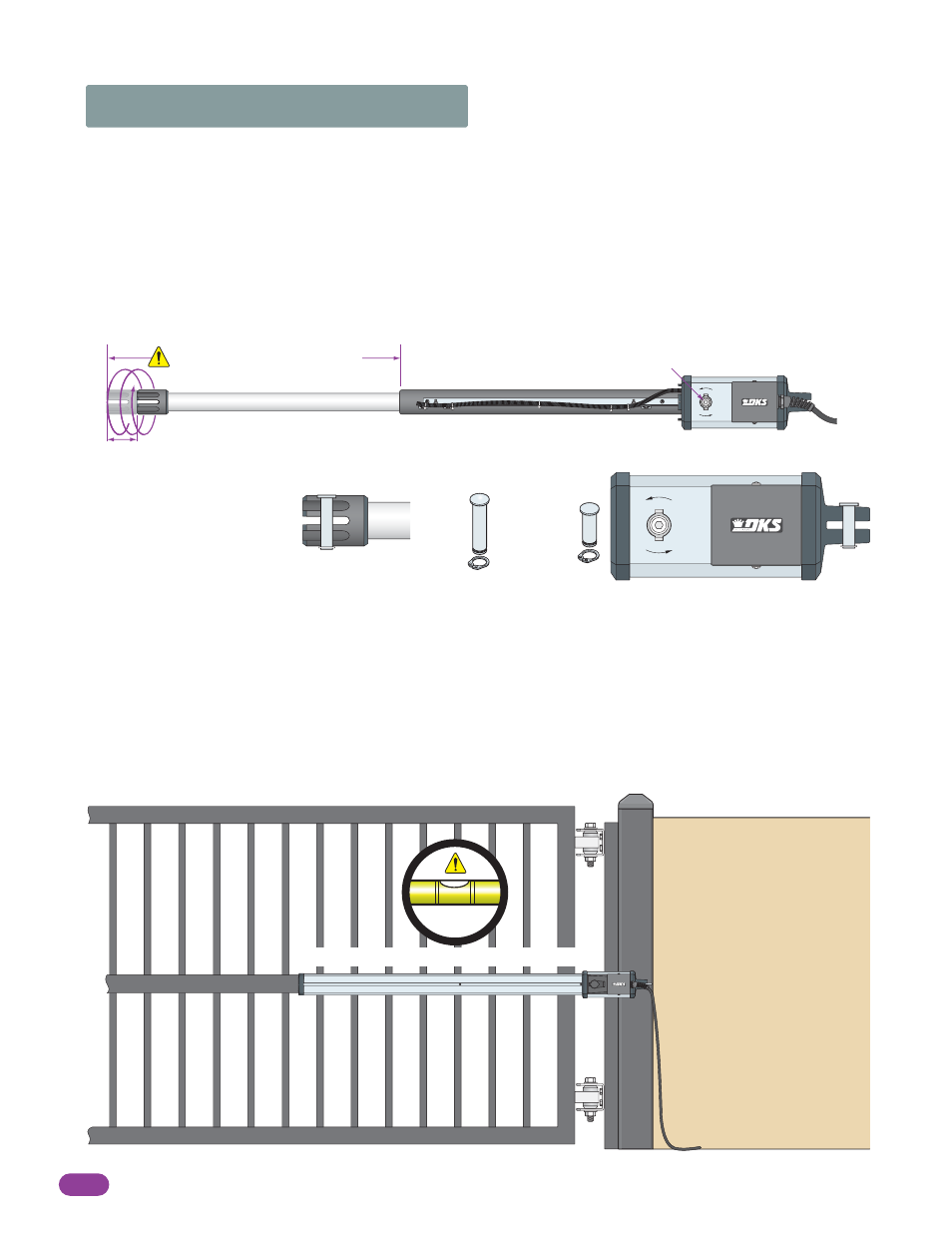

1.4 Mounting Actuator Arm

Gate must be in good working condition before the actuator arm can be installed. Determine what direction the actuator arm

will open the gate “Open to the Inside” or “Open to the Outside”(See previous 2 pages).

The brackets need to be fabricated before the arm can be installed. Brackets will vary in size depending on the opening direction

of the gate and the thickness of the wall the actuator arm will attach to. They can be attached to the wall and gate by welding

and/or mechanically, depending on the type wall and gate. The brackets must be perpendicular to the wall and/or gate and

horizontally level. Make sure the brackets will be VERY secure when fastened to the wall and gate.

If the brackets are going to be welded to the gate and/or wall, only tack weld the brackets with the arm attached. Protect the arm

from welding sparks during the tack welding. Remove arm before completely welding around the brackets. Make sure that

brackets and actuator arm are level when tack welding them! The arm will not operate properly if out of level. Make sure

powered shaft is not bottomed out. Completely weld around brackets.

It is very important that the powered shaft is not fully extended when installed on the gate (bottoming out). This will damage the

arm. To prevent this, manually release the arm and fully extend the powered shaft. Rotate it back two full turns before installing

the arm.

A support bar that spans the entire length of the gate must be installed to keep the pickets from bending. Do not mount the

front bracket directly to gate pickets!

Bracket Fabrication

Clevis Pins

Welding Brackets to Surfaces

Gate Support Bar

Prevent Powered Shaft Bottoming Out

Powered shaft rotated back 2 turns.

Fully Extended (Bottomed Out)

OPEN

O PE

N

OPEN

O PE

N

Manually release

with allen wrench.

Powered Shaft

Actuator arm and brackets MUST be level!

Retaining Rings

Rear Pin

(Short)

Front Pin

(Long)

Note: Front clevis pin MUST fit

into countersunk hole to allow

retaining ring to be installed.