6 secondary entrapment protection wiring – Controlled Products Systems Group 1150-080 User Manual

Page 18

1150-065-F-1-11

16

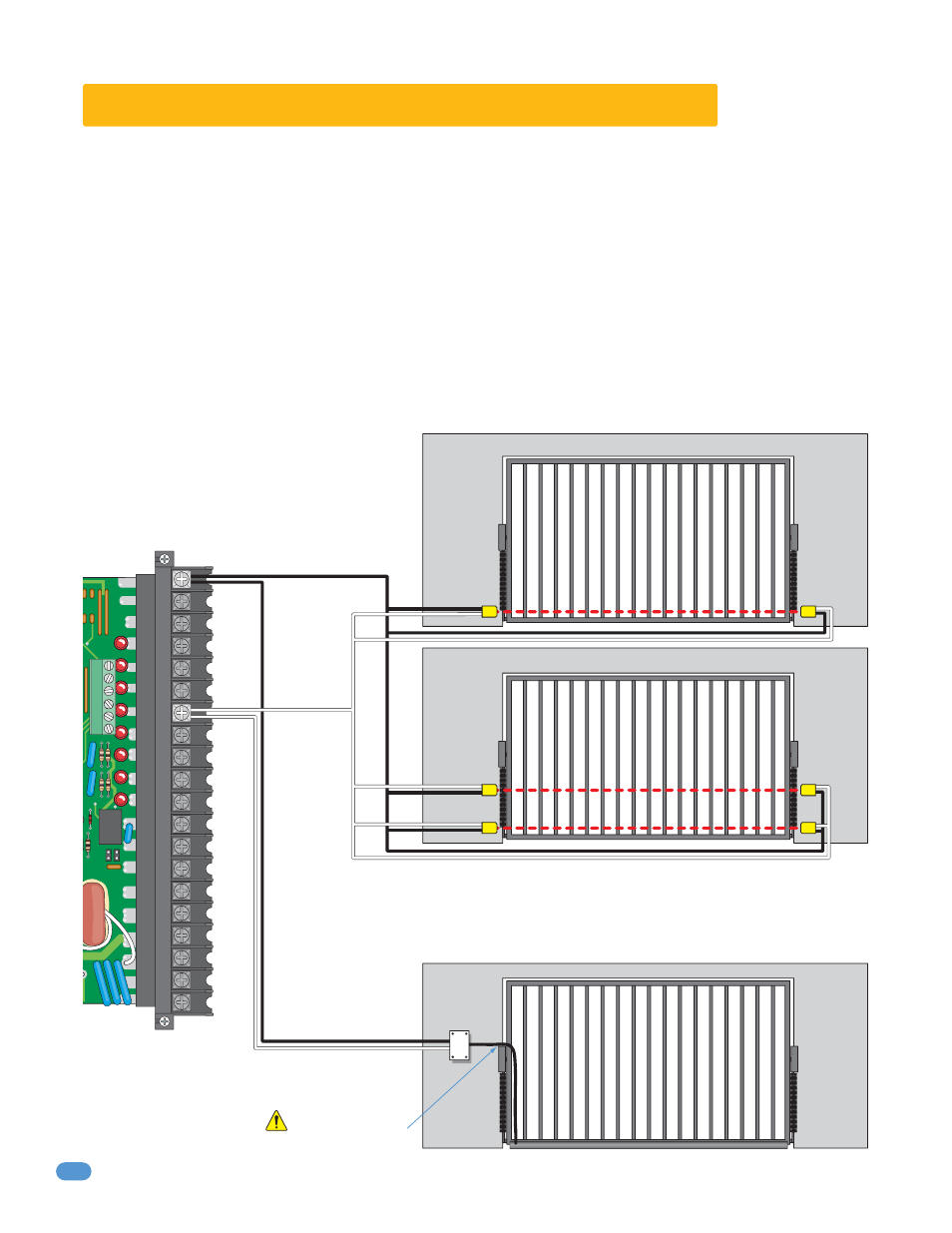

2.6 Secondary Entrapment Protection Wiring

Secondary entrapment prevention devices must be installed to insure a safe operating environment and reduce the risk of

personnel entrapment. Secondary entrapment prevention may be provided by a combination of both type sensors (UL 325 Type

B1 and B2).

Avoid interference

with gate hardware.

•

Use only UL listed (or equivalent) sensors.

•

Sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter reachable by a

moving gate or barrier. Additional sensors should be added for additional protection where entrapment zones exist.

Actual placement of sensors is dependent on the installation requirements.

•

Inputs from sensors to circuit board are Normally Open (NO).

•

Disconnect power to gate operator before installing the sensors.

•

Photo-cell should be placed so that an entrapment cannot occur at the lower travel of the gate. Do not place the

photo-cell so high that a person could be trapped under the gate without activating the photo-cell.

•

If high bed vehicles access the gate, a second photo-cell should be placed so that the photo-beam cannot scan

under the vehicle.

•

Photo-cells may require separate

power depending on model used.

•

Hardwired contact sensors must be located and wiring arranged so that the communication

between the sensor and the gate operator is not subjected to mechanical damage.

•

Additional contact sensors should be added where multiple entrapment zones may exist.

Non-Contact Sensor (Type B1)

Contact Sensor (Type B2)

NO

NC

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Junction

Box

Com

N. O.

High Bed Vehicles (Multiple Beams)

Typical Vehicles (Single Beam)