Section 14 maintenance and troubleshooting, 1 instrument maintenance, 2 sensor maintenance – Hach-Lange ORBISPHERE K1100_M1100 Operator Manual User Manual

Page 99: 1 equipment required, 2 sensor spot removal, 1 instrument maintenance 14.2 sensor maintenance, 1 equipment required 14.2.2 sensor spot removal

97

Section 14

Maintenance and Troubleshooting

14.1 Instrument maintenance

14.2 Sensor maintenance

The sensor spot needs to be replaced about once a year, though for M1100 sensors this will

also depend on the CIP frequency. The procedure is very simple and takes no more than a

couple of minutes.

Important Note:

The shelf-life of the K1100/M1100 LDO spot is 2 years prior to first use.

14.2.1 Equipment required

14.2.2 Sensor spot removal

CAUTION

Personal Injury Hazard. Any instrument maintenance should be carried out by a qualified

Hach Lange Service Technician. Please contact your local representative should you feel any

maintenance or instrument adjustments are required

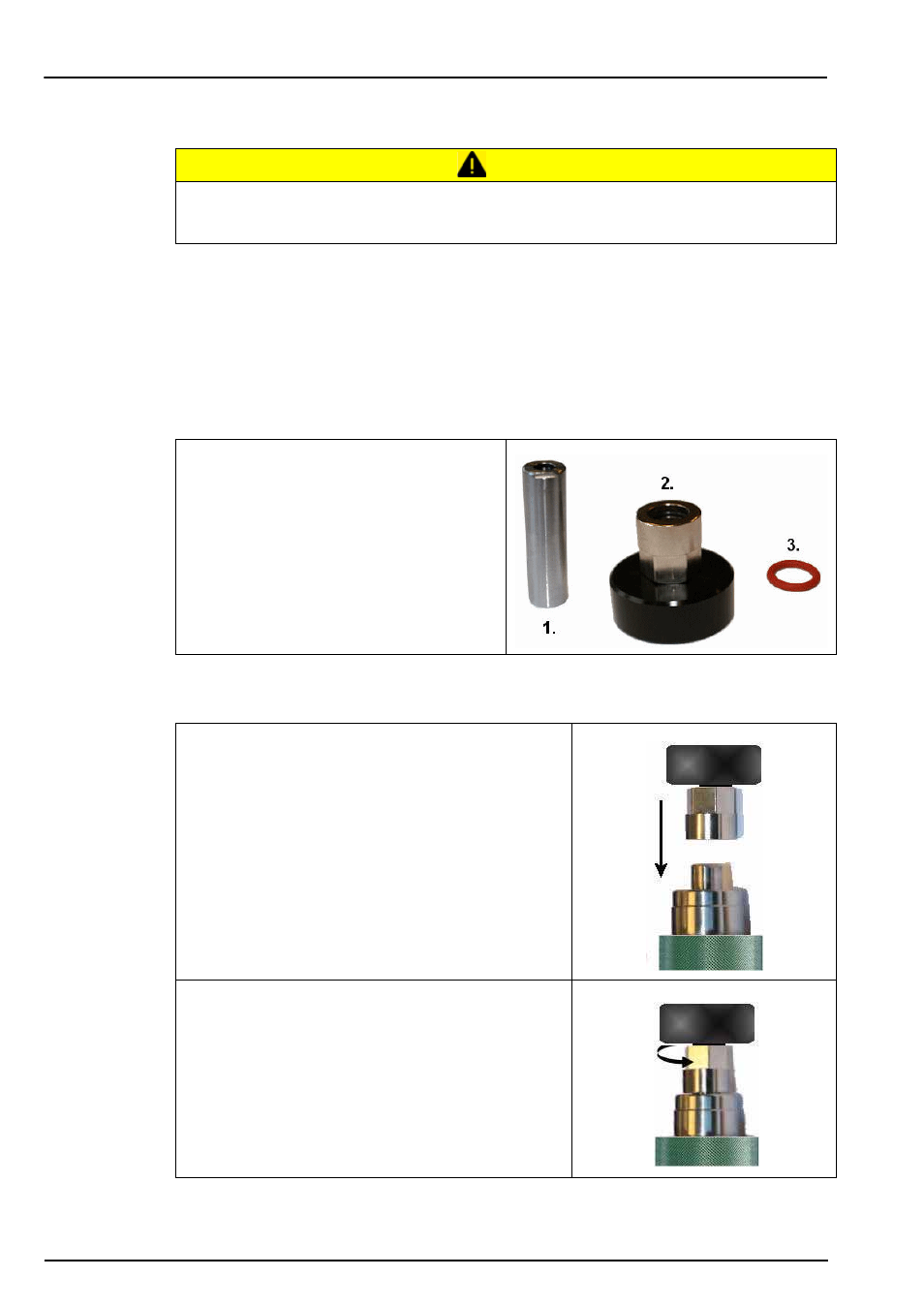

A replacement sensor spot (No. 1) and O-ring

(No. 3) supplied with the sensor spot.

The maintenance tool (No. 2) which is

delivered with the sensor.

1.

Push the maintenance tool (square sides upmost)

as far down as possible over the old sensor spot.

Continue to push down on the tool and turn gently

until the square sides of the tool and the square

slots of the sensor spot engage. The tool should

then drop into position.

2.

Turn the tool counter clockwise to unscrew the old

sensor spot.