9 sensor installation, 1 sensor positioning information, 2 recommended sample flow rate – Hach-Lange ORBISPHERE K1100_M1100 Operator Manual User Manual

Page 37: 3 sensor insertion, Installation

35

Installation

3.9 Sensor installation

3.9.1 Sensor positioning information

The sensor must be installed in a socket or flow chamber that allows contact with the sample

fluid to be analyzed.

The sensor and measuring instrument are connected by a cable. The standard sensor cable

lengths are 3, 5, 10, 15 and 20 meters.

Ensure that the sensor will be mounted:

•

perpendicular to the pipe

•

horizontal

•

on a horizontal pipe section (or on flow-ascending vertical pipe)

•

minimum of 15 meters away from the pump's discharge side

•

in a place where the sample flow is stable and rapid, and as far as possible from:

•

valves

•

pipe bends

•

the suction side of any pumps

•

a CO

2

injection system or similar

Note:

There may be situations where not all the above conditions can be met. If this is the case, or you

have any concerns, please consult your Hach Lange representative to appraise the situation and define the

best applicable solution.

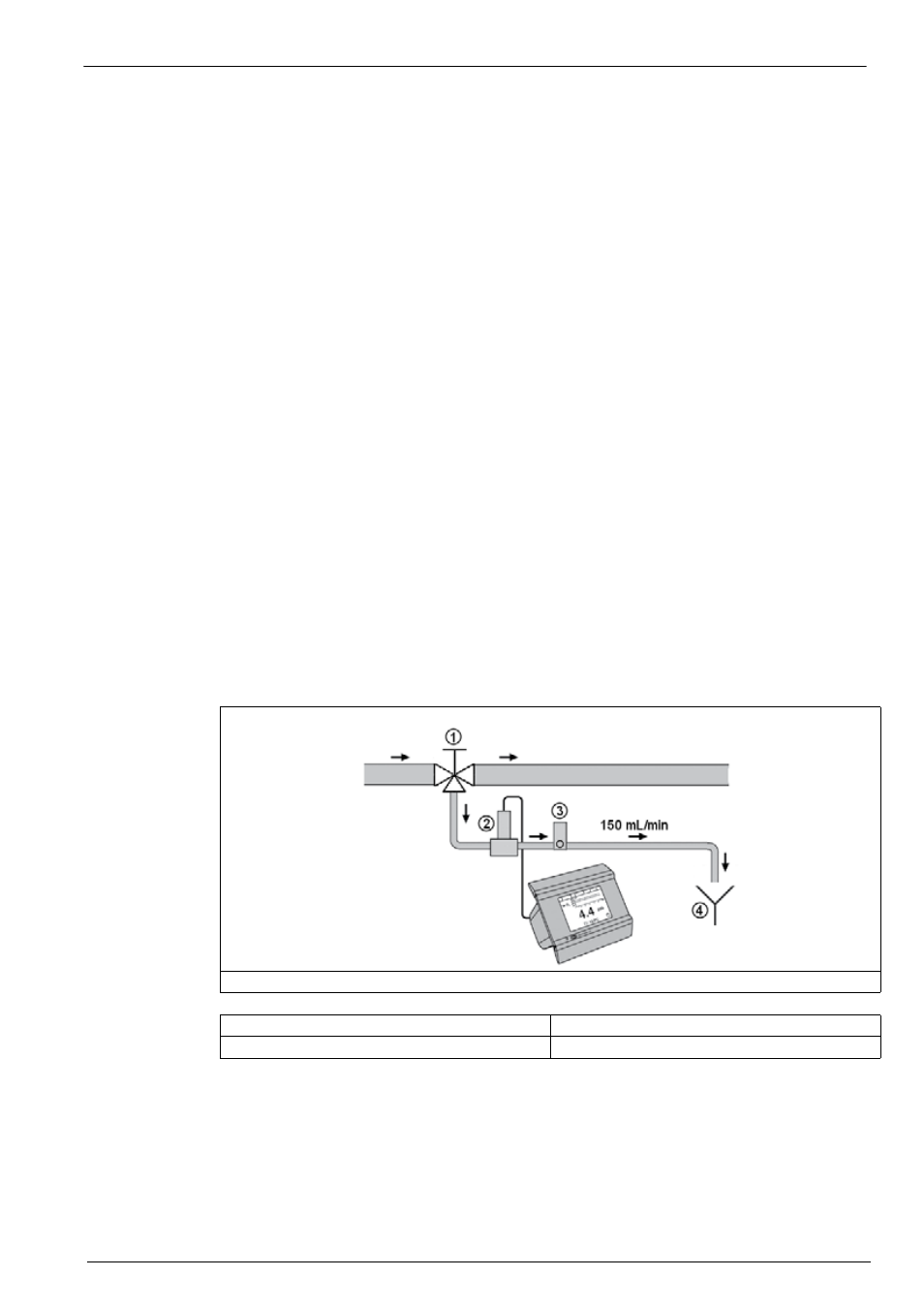

3.9.2 Recommended sample flow rate

For optimal response time, the recommended sample flow rate for both the K1100 and M1100

sensors is 150 mL/min.

Control the flow with the outlet valve on the flow meter (No. 3 in

below) to avoid foam

developing inside the flow chamber which could lead to erroneous oxygen measurement values.

3.9.3 Sensor insertion

•

Insert the sensor straight into the flow chamber or socket. Do not twist the sensor.

•

Hand tighten the attaching collar.

•

Connect the sensor cable.

•

Check for leaks; replace O-rings if product leaks are visible.

Figure 20 Typical measurement schematic

1.

Valve to redirect sample for measurement 3. Flow meter with outlet valve

2.

Sensor and flow chamber combination

4.

Drain