Cashco Siemens PS2 I/P User Manual

Page 94

Operation

94

SIPART PS2 Manual

A5E00074631-01

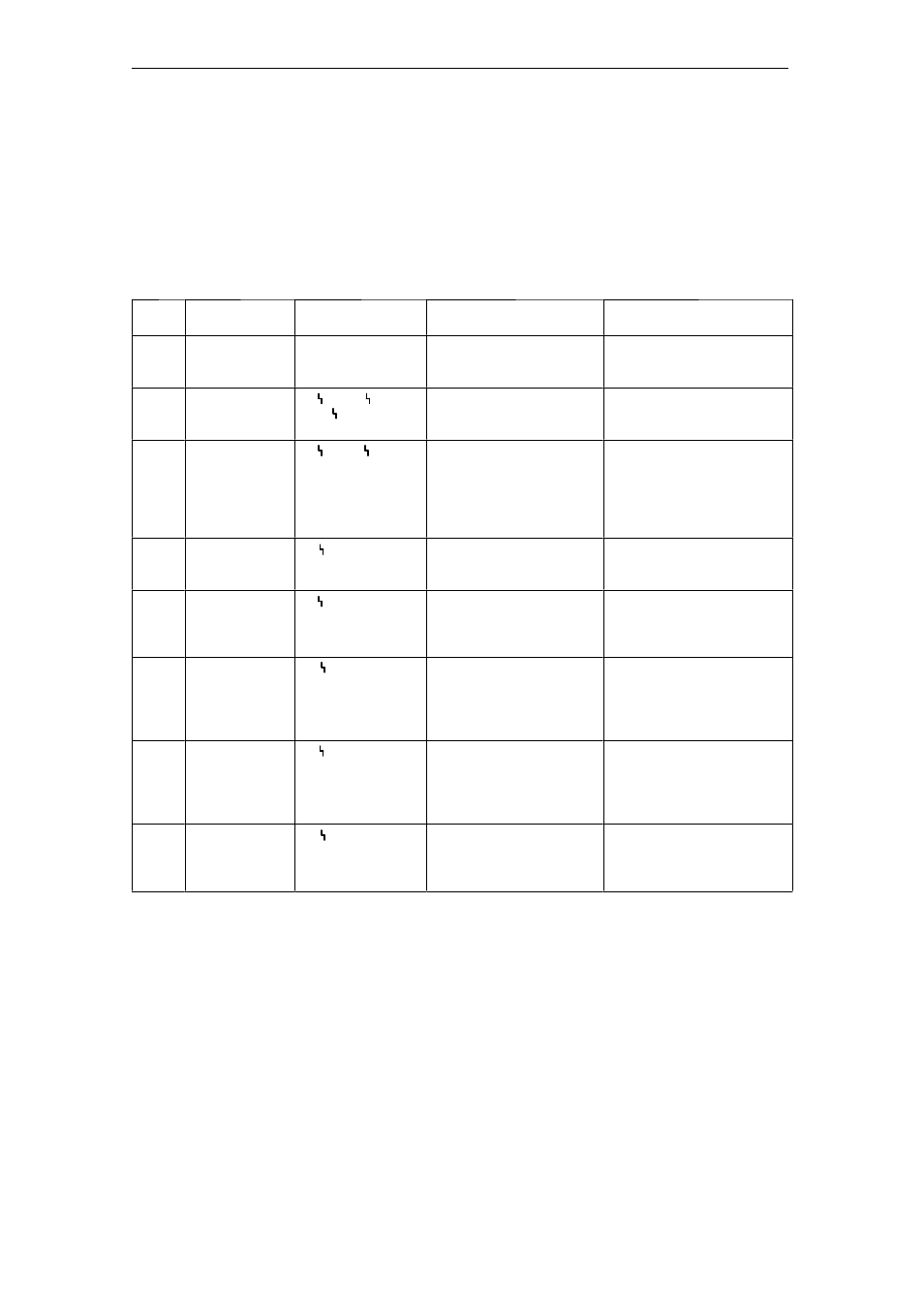

Table 3-2, page 94 shows which events can activate the fault message

output, how the parameters must be set for this event to be monitored,

when the fault message disappears again and where the possible

causes of the fault lie.

In automatic and manual operation response of the fault message

output on the display shows which is the fault message trigger. The two

digits at the bottom left indicate the corresponding error code. If several

triggers occur at the same time, these are displayed cyclically. The

instrument status which also contains all fault messages can be called

via HART with the command #48.

Error

code

Event

Parameter

setting

Fault message dis-

appears when ...

Possible causes

1

Remaining con-

trol error

always active

... the control error has

disappeared again

Compressed air missing,

actuator fault, valve fault

(e.g. blockade).

2

Instrument not

in automatic

mode

47. FCT= nA

or =

nAB

... the instrument is

brought into automatic

mode

The instrument is configured

or is in manual operation.

3

Digital input DI1

or DI2 active

47. FCT= nAB

and digital function

BIN1 or BIN2 to

”on”

... the digital input is no

longer activated

The contact connected to

the binary input has become

active (e.g. stuffing box

monitoring, excess

pressure, temperature

switch).

4

Limit value

Number of stro-

kes exceeded

50. STRK¸OFF

... the stroke counter is

reset or the limit value

increased

The total distance traveled

by the actuator exceeded

the set limit value.

5

Limit value

change of di-

rection excee-

ded

51. DCHG¸OFF

... the change of direction

counter is reset or the limit

value increased

The number of changes of

direction exceeded the set

limit value.

6

Limit value bot-

tom hard stop

exceeded

52. ZERO¸OFF

39.YCLS = do or

up do

... the deviation of the stop

disappears or the

instrument is re--initialized

Wear of the valve seat, de-

posits or foreign bodies in

the valve seat, mechanical

maladjustment, slip clutch

maladjusted.

7

Limit value

top hard stop

exceeded

53. OPEN¸OFF

39 YCLS = up or

up do

... the deviation of the stop

disappears or the

instrument is re--initialized

Wear of the valve seat, de-

posits or foreign bodies in

the valve seat, mechanical

maladjustment, slip clutch

maladjusted.

8

Limit value

dead zone

adaptation ex-

ceeded

53. OPEN¸OFF

34.DEBA = Auto

... the limit value is

dropped below again

Increased stuffing box

friction, mechanical lots of

the position feedback

Table 3-2

Events which can activate the fault message output