4 assembly procedure – Cashco Siemens PS2 I/P User Manual

Page 39

Preparing for Operation

39

SIPART PS2 Manual

A5E00074631-01

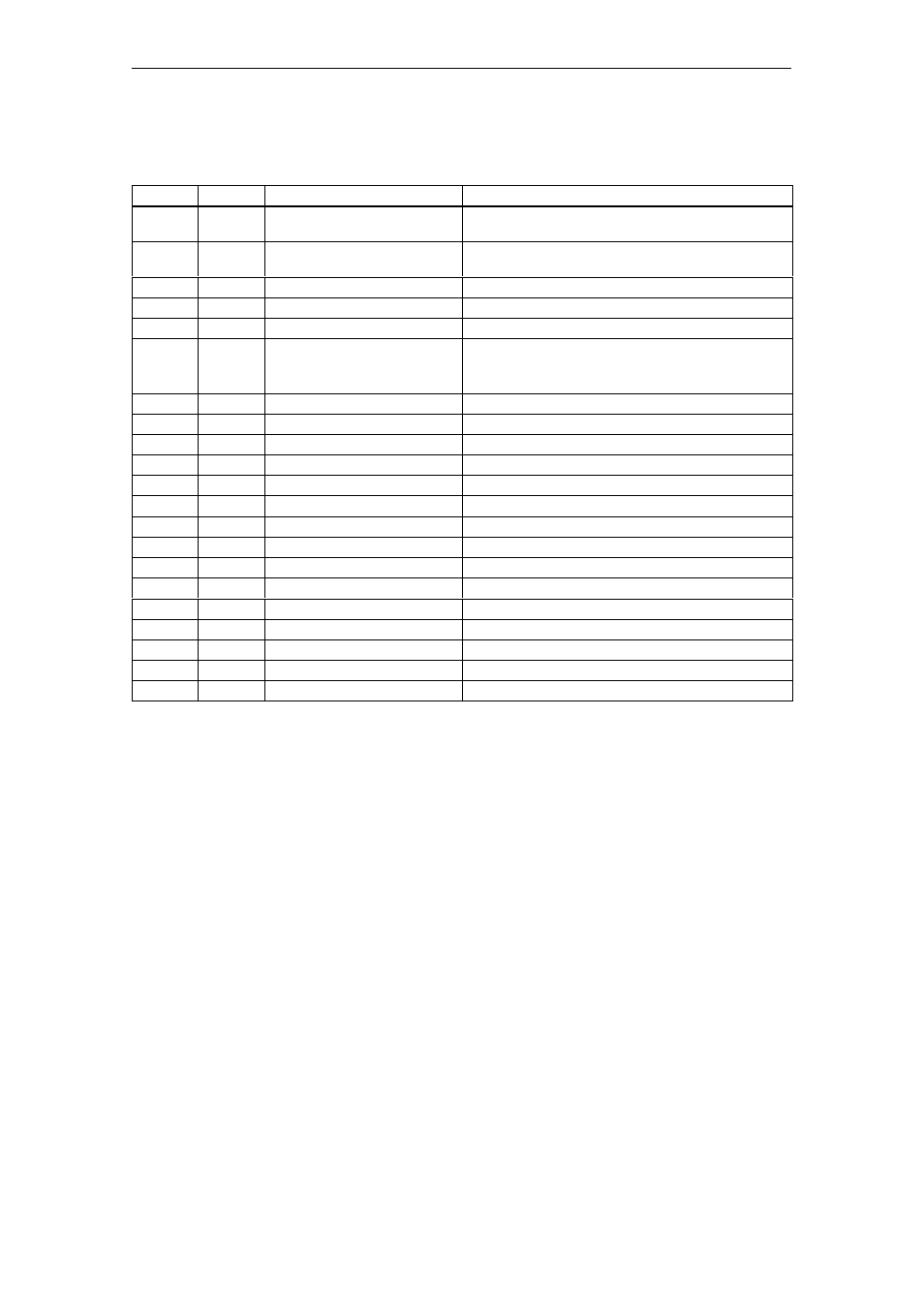

3.3.3 Mounting kit ”linear actuator” 6DR4004-8V and 6DR4004-8L

The scope of delivery of the mounting kit” linear actuator IEC 534

(3 mm to 35 mm)” are contained (ser. no. see figure 3-6, page 41):

Ser. no. pieces

Designation

Note

1

1

NAMUR mounting kit bracket

IEC 534

Standardized connection for mounting console with

ledge, column or plane surface

2

1

Pick--up bracket

Guides the roller with carrier pin and turns lever

arm

3

2

Clamping assembly

Mounting of pick--up bracket on actuator spindle

4

1

Carrier pin

Assembly with roll (5) on lever (6)

5

1

Roll

Assembly with pin (4) on lever (6)

6

1

Lever NAMUR

For stroke range 3 mm to 35 mm

For stroke ranges> 35 mm to 130 mm (special deli-

very), lever 6DR4004-8L is required additionally

7

2

U bolt

Only for actuators with columns

8

4

Hexagon head screw

M8 x 20 DIN 933-A2

9

2

Hexagon head screw

M8 x 16 DIN 933-A2

10

6

Lock washer

A8 -- DIN 127-A2

11

6

Flat washer

B 8,4 -- DIN 125-A2

12

2

Flat washer

B 6,4 -- DIN 125-A2

13

1

Spring

VD-115E 0.70 x 11.3 x 32.7 x 3.5

14

1

Spring washer

A6 -- DIN 137A-A2

15

1

Lock washer

3.2 -- DIN 6799-A2

16

3

Spring washer

A6 -- DIN 127-A2

17

3

Socket cap screw

M6 x 25 DIN 7984-A2

18

1

Hexagon nut

M6 -- DIN 934-A4

19

1

Square nut

M6 -- DIN 557-A4

21

4

Hexagon nut

M8 -- DIN 934-A4

22

1

Guide washer

6.2 x 9.9 x 15 x 3.5

3.3.4 Assembly procedure (see figure 3-6, page 41)

1. Mount clamping assembly (3) with hexagon socket cap screws

(17) and lock washer (16) on the actuator spindle.

2. Insert the pick--up bracket (2) into the recesses of the clamping

assembly. Set the necessary length and tighten the screws so that

the pick--up bracket can still be shifted.

3. Push the roll (5), spring (13) and guide washer (22) onto the pin (4).

4. Insert the pin in the lever (6) and assemble with nut (18), spring

washer (14) and washer (12).

5. The value of the stroke range specified on the actuator or if this

does not exist as a scaling value, the next greatest scaling value is

set. The center of the pin must be in line with the scaling value.

The same value can be set later under parameter 3.YWAY in

commissioning to display the way in mm after initialization.

6. Assemble the hexagon socket cap screw (17), spring washer (16),

washer (12) and square nut (19) on the lever.

7. Push the premounted lever onto the positioner axis up to the stop

and fix with the hexagon socket cap screw (17).