Cashco 764T Temperature Controller User Manual

Model 764t, Pneumatic temperature controllers

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

SECTION I

I. DESCRIPTION AND SCOPE

The Model 764T is a temperature controller with an integral, rigid insertion bulb used for sensing temperature, and

outputting a pneu mat ic signal proportional to the deviation from the setpoint.

This IOM-764T does not cover use of oxygen as the "instrument air" fl uid. Such an application is outside the scope

of this IOM.

With proper materials and pipe sizes, the 764T can be used to measure the tem per a ture of liquid, gaseous, or va por

service. The installation of the thermal bulb can be direct or in di rect using a thermal well. Refer to Technical Bulletin

764T-TB for de sign and selection rec om men da tions.

IOM-764T

12/13

Abbreviations Utilized:

IAS - Instrument Air Supply

ES - Electrical Supply

CW - Clockwise

SIG - Signal

TC - Temperature Control valve

CCW - Counter Clockwise

P/P - Pneumatic-to-Pneumatic

P1 - Inlet Pressure

REV - Revolution or Reverse

TC - Temperature Controller

P2 - Outlet Pressure

DIR - Direct

TI - Temperature Indicator

TR - Condensate Trap

FS - Flow Switch

SRV - Safety Relief Valve

PB - Proportional band

SOV - Solenoid Valve

SECTION II

II. INSTALLATION

Location of the thermal bulb into the medium

being con trolled is crit i cal.

Always insert the maximum bulb length into

the medium.

Always locate the bulb at a point downstream

of a heat exchanger to assure a near-equal

dis tri bu tion of the tem per a ture across the con-

tainment cross-section.

Always locate the control valve doing the tem-

per a ture control no further than 6-10 feet (2-3

meters) away from the controller when the

control valve does not have a po si tion er.

Do not use a thermal well unless the Owner's

process conditions, safety considerations or

main te nance pro ce dures require such; a ther mal

well enters an extra time response delay (i.e.

reduction in sensitivity) to the closed loop.

If a thermal well is required,to maximize heat

transfer effi ciency, locate on the top of a pipe

(vertical or at a 45° angle), duct, or at a 45°

angle to a vertical wall or horizontal top, when

possible, to allow fi lling of "void space" in well

with a suitable liquid heat transfer medium.

(See Figure's 4 and 5).

If a thermal well must be installed in a hor i zon tal

ori en ta tion, attempt to "pack" the "void space"

with steel or SST wool at bulb in ser tion. Use of

the well packing will in crease thermal effi ciency

(re duce time con stants) above that of a "dead

air" space in the "void space"; i.e. dead air space

acts as an "in su la tor" to heat transfer.

f.

a.

b.

c.

d.

e.

MODEL 764T

PNEUMATIC TEMPERATURE CONTROLLERS

1

.

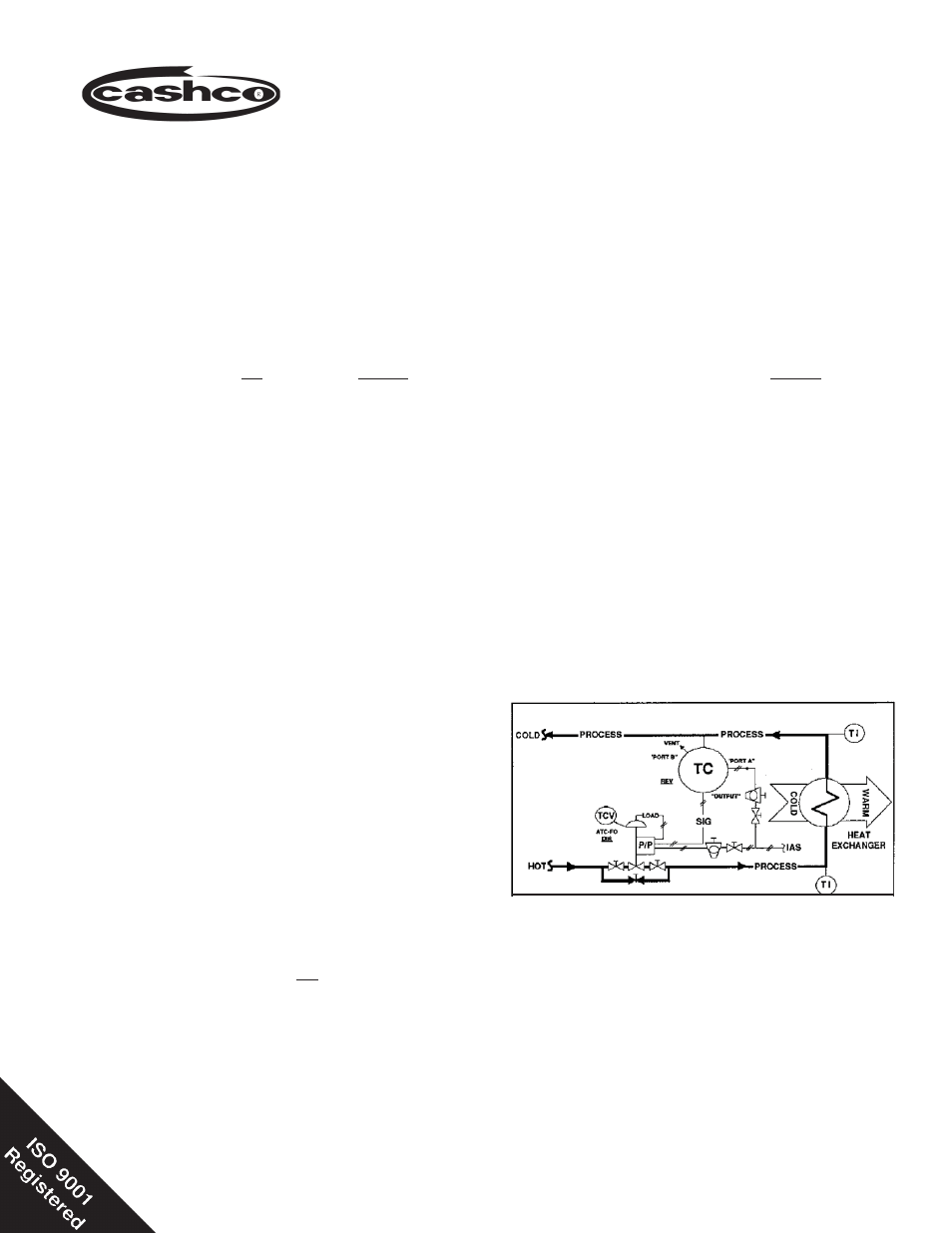

Figure 1: Typical Direct Cooling Application