Fluidic data – Burkert Type 8715 User Manual

Page 18

18

Technicaldata

Type 8700, 8701, 8703, 8705

6.6.

fluidic data

6.6.1. overview of measurement

specifications

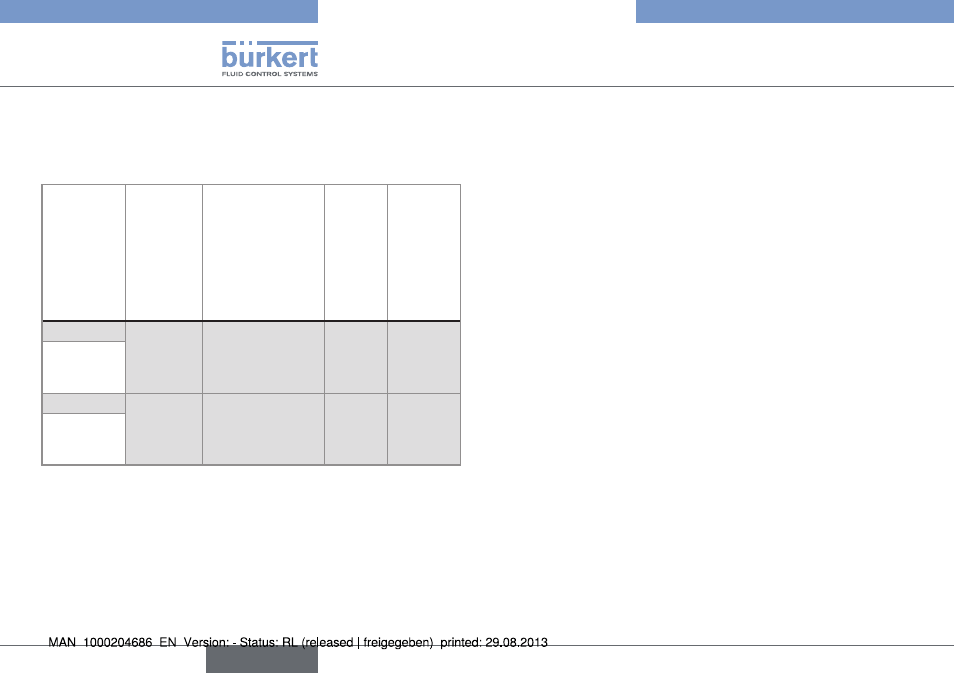

Device

types

Full scale range, ref.

to N2 (lN/min)

Measuring accuracy

(after heating time)

Span/control range

Settling time (MFC)

or response time

(MFM) (ms)

8700, 8710

0.01 … 15

± 1.5 % of the

measured value

± 0.3 % of the full

scale

1 : 50

< 3000

8705, 8715

8701, 8710

0.01 … 80

± 0.8 % of the

measured value

± 0.3 % of the full

scale

1 : 50 *) < 300

8703, 8713

*) Higher span (e.g. 1:100) possible on request

Repeatability: ± 0.1% of the full scale.

6.6.2. operating fluids

• Operating fluids: clean, dry gas.

• Operating fluid for UL devices: neutral, uncontaminated gas. Other

hazardous gases are possible on request; the devices do not

release any hazardous gases under normal operating conditions.

• Calibration fluid: operating gas or air.

• Max. operating pressure: 10 bar (depending on the nominal size of

the valve).

To obtain the required measuring accuracy or control quality,

but also to respect the safety requirements, the gas or

gaseous mixture must conform to the following safety criteria,

compliant with ISO standard 8573-1 (Compressed air -

Part 1: Contaminants and purity classes):

• Particle size and maximum density: class 2:

Maximum particle size: 1 µm

1)

Maximum particle density: 1 mg/m³

1)

• Maximum dewpoint under pressure: class 4: 3°C

• Maximum oil concentration: class 1: 0.01 mg/m³

1)

1)

For more information refer to ISO 8573-1

English