Burkert Type 2002 User Manual

Page 4

For actuator size D (50 mm) the tube

8

is screwed and

sealed in the nipple

6

.

→

Release and remove screw

18

with socket spanner.

→

Remove disk springs

17

.

→

Remove actuator body

12

.

→

Only actuator size C (40 mm): Replace O-ring

11

.

→

Replace O-ring

36

.

Reinforcing ring

10

remains on the tube

8

.

→

Slide packing gland set

7

,

13

,

14

,

15

,

16

carefully out of the

tube

8

. Take care that the tube is not damaged.

→

Clean all replacement parts thoroughly after removal.

aSSembly

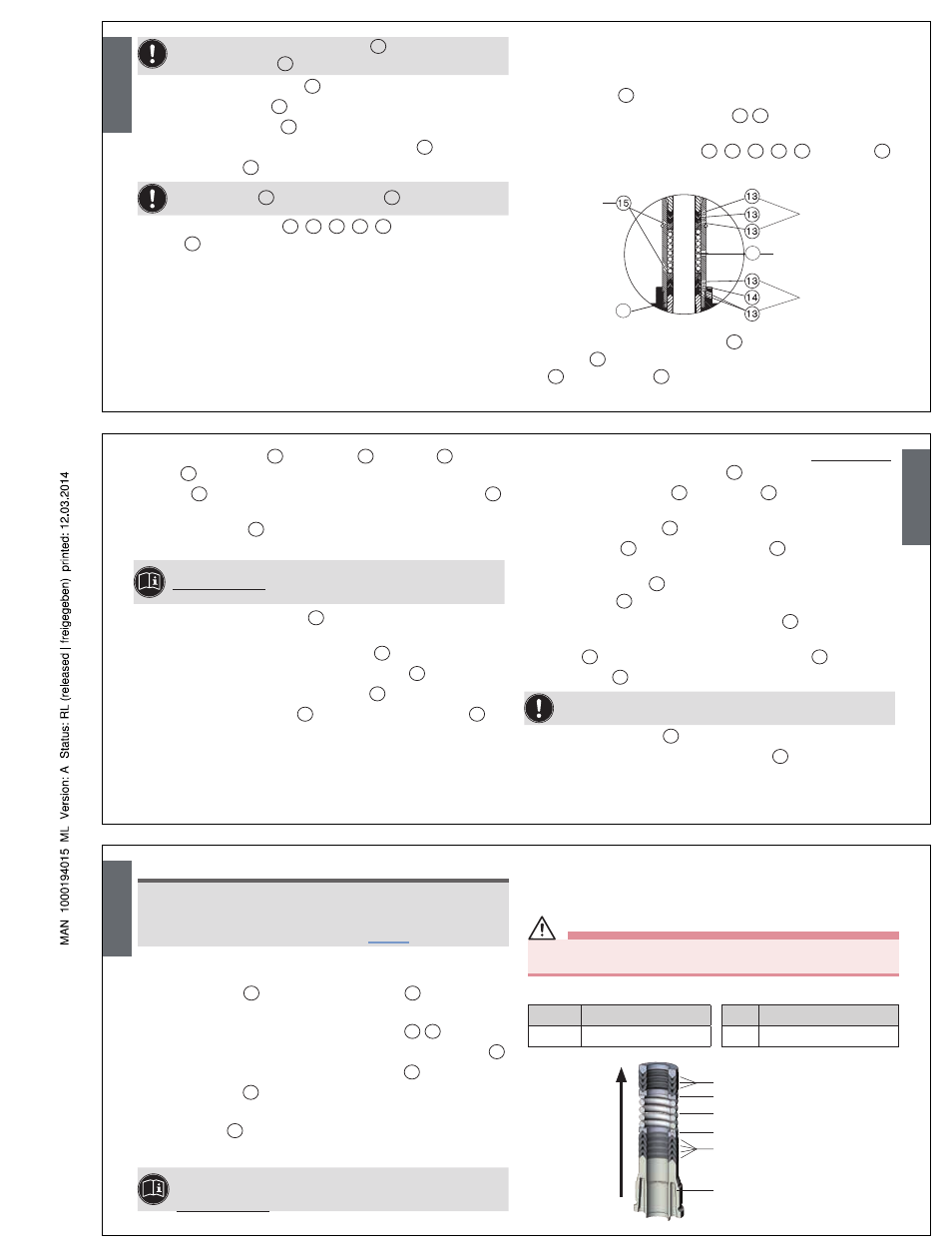

Rebuild packing gland set based according to the drawing:

→

Lubricate new wiper with silicone grease OKS 1110-3 and insert

into the tube

8

.

→

Lubricate individually chevron seal

13

14

liberally with silicone

grease OKS 1110-3.

→

Assemble packing gland set

7

,

13

,

14

,

15

,

16

in the tube

8

in the right sequence (see detailed drawing).

Chevron seal

Pressure

rings

Chevron seal

16

Pressure spring

7

→

Push packing gland into the tube

8

as far as the stop; clamp

nipples

6

to do this and screw in packing gland set with screw

18

. Remove screw

18

again.

English

→

Mount actuator body

12

, disk springs

17

and screw

18

on the

tube

8

.

→

Screw

18

with socket spanner; ensuring that the disk springs

17

are in a central position.

→

Lubricate spindle

2

lightly with silicone grease OKS 1110-3

and insert suitable assembly sleeve over spindle thread.

For information about the assembly sleeve, see:

www.burkert.com

→ Type 2000 → Maintenance-EU-ML,

section Installation Wrench.

→

Insert spindle through nipple

6

into actuator and remove

assembly sleeve.

→

For control function A: Place filler piece

19

on spindle.

→

For control function B: Insert pressure springs

35

.

→

For control function I: Insert filler piece

19

.

→

Place intermediate washer

20

and lightly lubricated O-ring

21

on

spindle.

The following operations must only be carried out with all valves:

→

Lubricate mounting actuator body

12

; lubricant Amblygon TA.

→

Remove old piston seal

23

from pistons

22

, clean groove and

lubricate well; lubricant Amblygon TA.

→

Insert new piston ring

23

.

→

Insert pistons

22

and supporting washer

24

and lightly lubricate

bearing surface.

→

Wet spindle thread

2

with special adhesive LOCTITE 274 and

screw on nut

25

.

→

Carefully screw in actuator on the swivel plate

3

(only put pressure

on the upper section of the swivel plate).

→

Screw

25

nut tightly and mount position indicator

26

.

→

Clamp body

1

.

Do not damage sealing edges when replacing the seal!

→

Replace graphite seal

5

.

→

Only for VA body: Lubricate nipple thread

6

with Klüber paste

UH1 96-402.

English

note!

Damage to the seat contour!

• During installation, take care that there is no damage to the seat

contour.

• Observe tightening torques according to “Tab. 1”.

→

For control function A (CFA): Pressurize lower control air con-

nection with compressed air (5 bar).

→

Screw in nipple

6

with actuator in valve body

1

.

→

Only for type 2002: Use sealing tape.

→

For control function A: Use pressure springs

28

29

.

→

Only actuator size G (100 mm) and H (125 mm): Insert washer

40

.

→

For control function B and I: Change O-ring

30

.

→

Replace O-ring

32

; to do this, remove transparent cap.

→

Lightly lubricate cover thread, lubricant Amblygon TA.

→

Mount cover

31

and screw tightly with special wrench.

→

Check the valve for function and leaks.

A detailed description about how to change spare parts and

maintenance of valves can be found at:

www.burkert.com

→ Type 2000 → Maintenance-EU-ML.

CHaNGe THe paCkING GlaND FoR ValVeS

WITH aCTUaToR SIze F (80 mm), G (100 mm),

H (125 mm) aND IDeNTIFICaTIoN "R"

DAnGer!

Risk of injury from discharge of medium and release of pressure!

• Before removing a device, switch off the pressure and vent the lines!

The seal set for the packing gland contains:

Item

Description

Item

Description

13, 14

7 chevron seal

7

1 spindle guide

Upper chevron seal

Upper pressure ring

Pressure spring

Lower pressure ring

Lower chevron seal

Spindle guide

Pushing direction

for packing gland parts

English