Burkert Type 2002 User Manual

Page 3

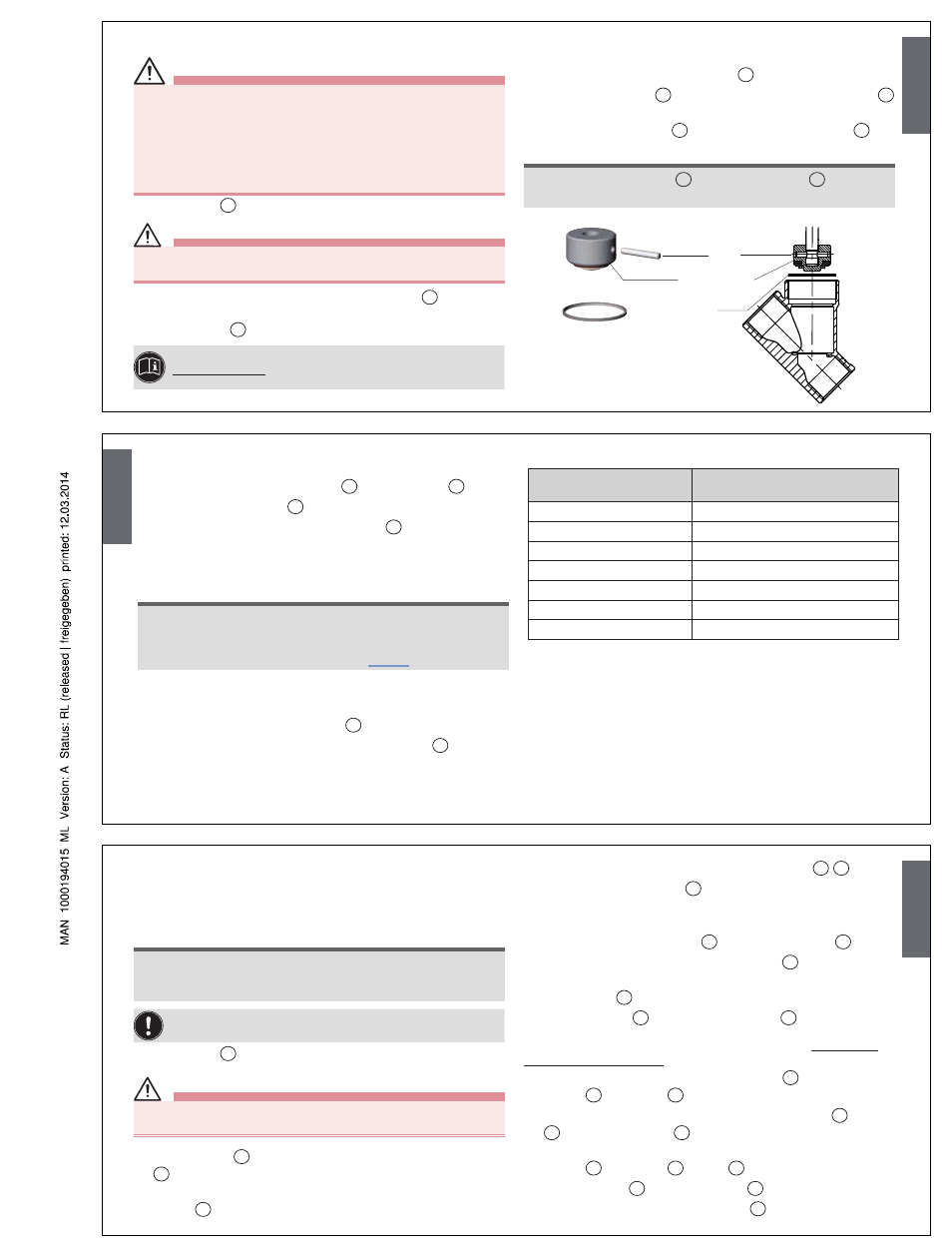

ReplaCING THe ValVe SeT

DAnGer!

Danger – high pressure!

• Turn off the pressure and vent the lines before loosening lines or

valves.

Risk of injury from improper maintenance!

• Maintenance may be performed by authorized technicians only!

• To screw on or unscrew valve body or actuator, use an open-end

wrench, never a pipe wrench, and observe tightening torques.

→

Mount valve

1

on the body.

CAutIon!

Danger through taut springs!

• Carefully open piston actuator!

→

Only for control function A (CFA): Release cover

31

with special

wrench until the springs are completely relaxed, holding up the

actuator body

12

against the hexagon.

For information about the special wrench, see:

www.burkert.com

→ Type 2000 → Maintenance-EU-ML,

section Installation wrench.

→

For control function A (CFA): Pressurize lower control air con-

nection with compressed air (5 bar).

→

Unscrew actuator on the valve body

1

.

→

Support swivel plate

3

with the help of a prism, knock out pin

4

with a pin punch and pull out swivel plate.

→

Mount new swivel plate

3

align and secure with new pin

4

.

note!

For valves with "R" sleeves

3*

, insert in swivel plate

3

and align

drilled holes.

Pin

Swivel plate

Graphite seal

English

→

Calk pin bores on both sides of the swivel plate with chisel or prick

punch.

→

Carefully remove old graphite seal

5

from valve body

1

.

→

Insert new graphite seal

5

.

→

Only for VA body: Lubricate nipple thread

6

with Klüber paste

UH1 96-402.

→

Only for type 2002: Use sealing tape.

note!

Damage to the seat contour!

• During installation, take care that there is no damage to the seat

contour.

• Observe tightening torques according to “Tab. 1”.

→

For control function A (CFA): Pressurize lower control air con-

nection with compressed air (5 bar).

→

Screw in valve actuator with nipple

6

into the body.

→

Only for control function A (CFA): Rescrew cover

31

with

special wrench.

→

Check the valve for function and leaks.

Tightening torques

DN

(mm)

Tightening torques

(Nm)

15

45

20

50

25

60

32

65

40

65

50

70

65

70

Tab. 1: Valve body tightening torques

English

CHaNGING THe Seal SeT

Change seal set with actuator with control function A (locked by

spring force in the rest position), control function B (opened by spring

force in the rest position) and control function I (dual acting)

note!

The actuator must be completely removed to replace all the seals.

A special Bürkert assembly sleeve is required to mount the packing

gland.

Do not use any pointed or sharp instruments!

→

Mount valve

1

on the body.

CAutIon!

Danger through taut springs!

• Carefully open piston actuator!

→

Unscrew cover

31

with special wrench holding up the actuator body

12

against the hexagon.

→

Only for actuator size G (100 mm) and H (125 mm): Remove

washer

40

.

→

For control function A: Remove pressure springs

28

29

.

→

Remove position indicator

26

with Allen key.

→

For control function A (CFA): Pressurize lower control air con-

nection with compressed air (5 bar).

→

Screw actuator on the nipple

6

out of the valve body

1

.

→

Carefully screw in actuator on the swivel plate

3

(only put pressure

on the upper section of the swivel plate).

→

Release nuts

25

.

→

Remove pistons

22

with supporting washer

24

.

The following operations must only be carried out with valves

without identification "R":

→

For control function A: Remove filler piece

19

with intermediate

washer

20

and O-ring

21

.

→

For control function B: Remove intermediate washer

20

, O-ring

21

and pressure spring

35

.

→

For control function I: Remove filler piece with intermediate

washer

20

and O-ring

21

(spring

35

missing).

→

Remove spindle

2

from actuator body

12

and clean spindle thread.

→

Clamp actuator on the nipple hexagon

6

.

English