Draw-Tite 3203 ROUND BAR WT. DIST. User Manual

Installation instructions

112901-02/27/12 REV.B

©2012 CEQUENT PERFORMANCE PRODUCTS, INC.

Litho in USA

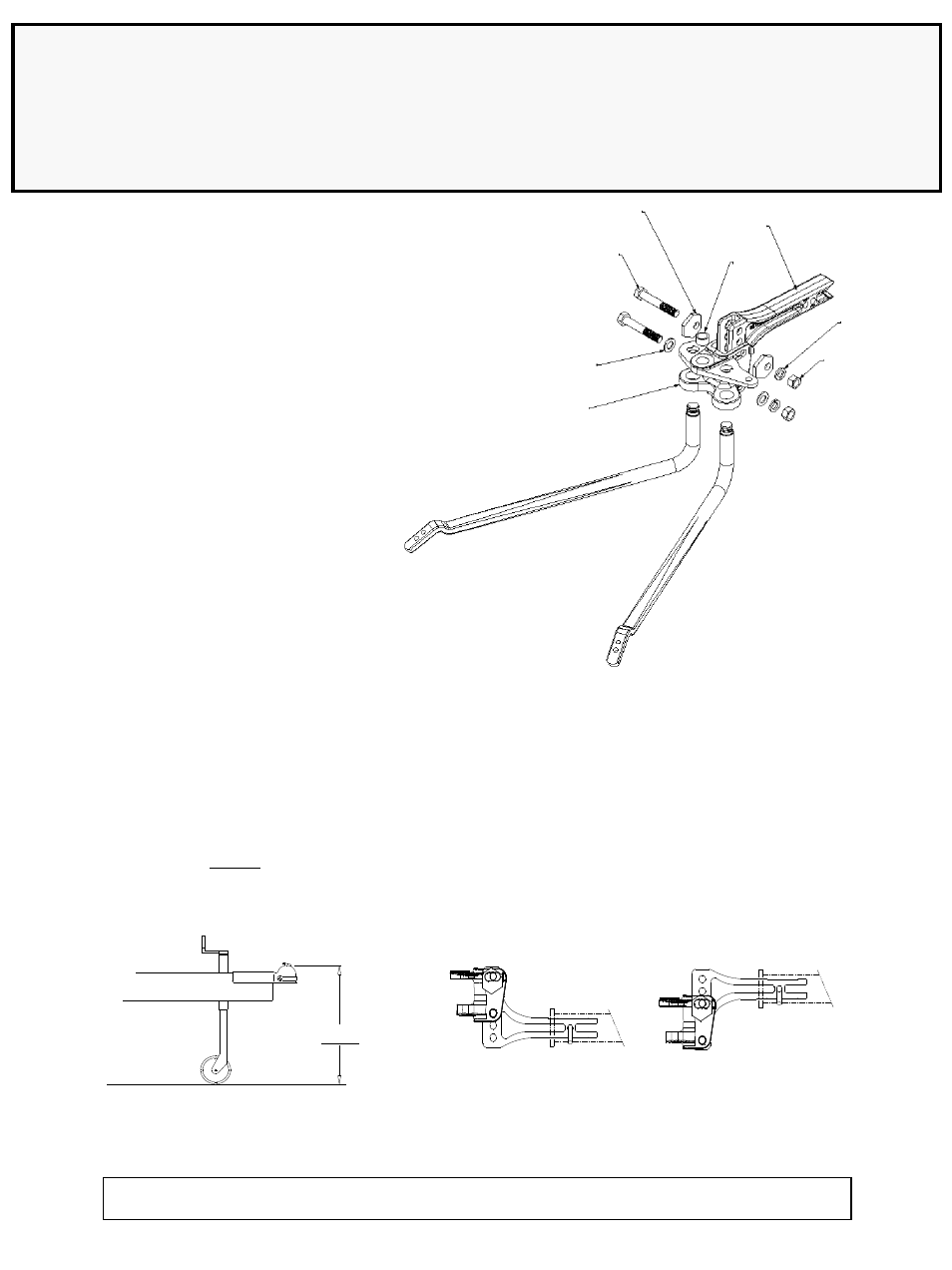

SMALL PARTS

PACKAGES 66014K AND 61224

For Installation Assistance or Technical Help, Call 1-800-758-0869

INSTALLATION INSTRUCTIONS

Heavy Duty Round Bar Adjustable

Weight Distributing Hitches

PLYMOUTH, MI.

DEALERS: Give these instructions to your customers.

INITIAL SET-UP

1. Line up

tow vehicle and trailer on level pavement,

in straight-ahead position, uncoupled.

2. Level the trailer and measure and record the

distance from the ground to the top of the ball

socket (dimension Fig. 1).

3. Select a hitch ball with a diameter that matches

the trailer coupler size. The three most common

sizes are 1-7/8", 2", and 2-5/16". Select ball with

1-1/4" or 1" threaded shank that is V-5 rated equal

to or greater than trailer gross vehicle weight

rating (GVWR).

WARNING: Raised balls usually have reduced load

ratings. Ball rating MUST equal or exceed trailer GVWR.

4. Attach hitch ball to the ballmount (G). A standard height hitch balls

with 1-1/4" shanks are supplied with lock washers and nuts (If you must use

a 1” shank ball, use

reducer

bushing (B) to reduce hole size in ballmount (G)

to 1”). Always use a lock washer and place washer next to nut. Unless other-

wise specified by ball manufacturer torque ball nut to 450 ft/lbs for 1-1/4" nut,

250 ft/lbs for 1" nut.

5. Some installations may require a longer hitch bar (D). Extended bumper guards, pickup truck "caps", or rear mounted spare tires

can limit turn angles unless a longer bar is used. Individual hitch bars (D) are available in various sizes.

6. Insert the hitch bar (D) into the hitch box and install a pull pin. Place ballmount (G) onto hitch bar and move up or down for proper

height. Hitch bar may be used in either the up or down position (see Fig. 2).

NOTE: Ball height should be greater

than coupler height (measured in step 1) to compensate for vehicle "squat”

(approximately 3/4” to 1”).

Fig. 1

Fig. 2

D

L

K

G

F

J

E

B

* SHOWN WITH NEW INTEGRATED

CAM SPRING BARS