Atas international, inc – ATAS Flat Sheet and Coil Stock User Manual

Page 2

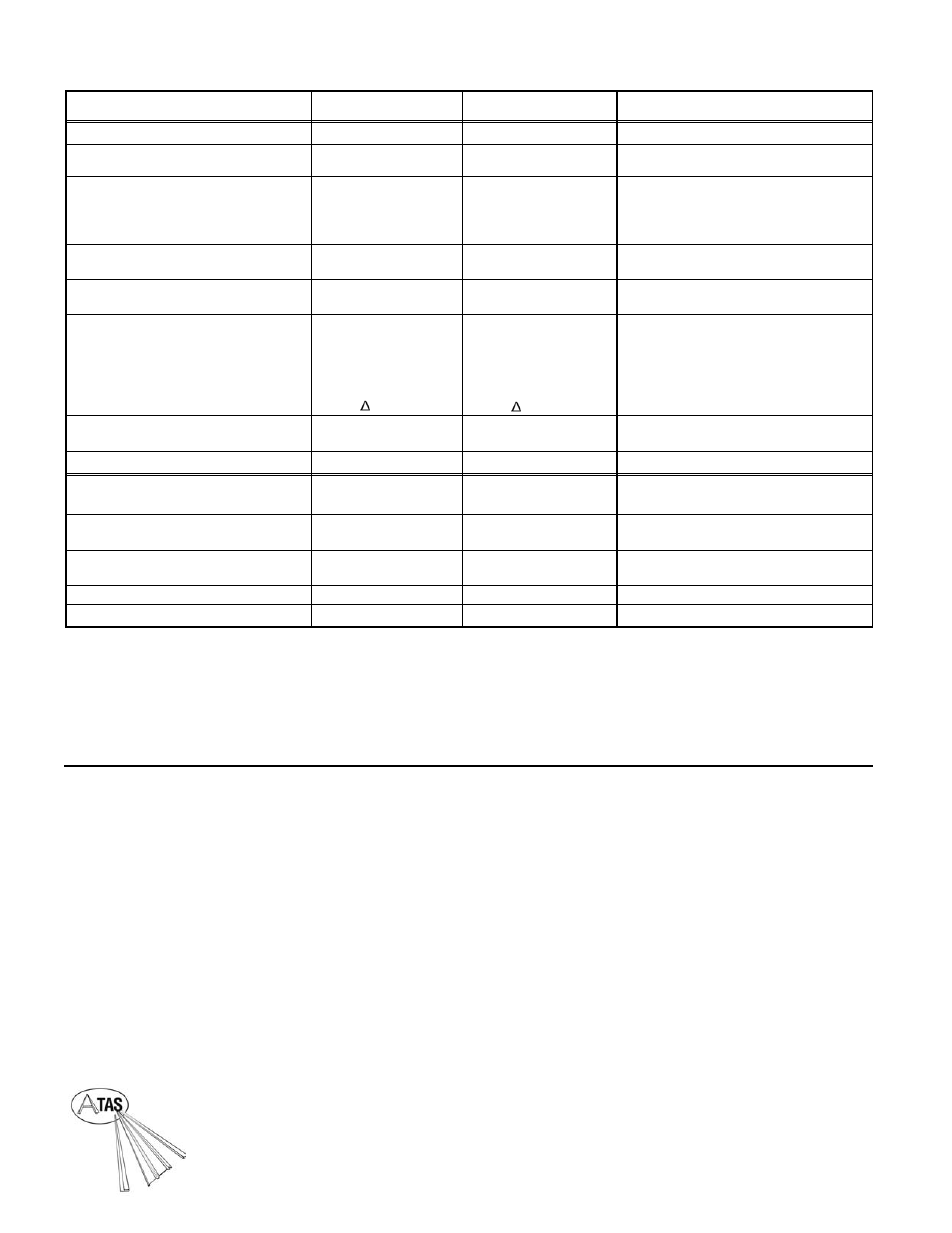

Finish Coating shall meet the following performance criteria:

Property

Result-Aluminum

Result-Steel

Test Designation

60° Specular Gloss

25-40

25-40

ASTM D 523

Pencil Hardness

HB - H

HB - H

ASTM D 3363

NCCA 11-12

Flexibility:

T-Bend

1-T (1)

2-T (1)

ASTM D 4145, (NCCA 11-19)

No cracking or tape removal of film

Mandrel

No cracking

No cracking

ASTM D 522

180 bend around 1/8” mandrel

Adhesion

Impact

Acceptable (2)

Acceptable (2)

ASTM D 3359, (NCCA 11-5)

Reverse Impact

Acceptable (2)

Acceptable (2)

ASTM D 2794, (NCCA 11-6)

Abrasion

Falling Sand

50 liters minimum

50 liters minimum

ASTM D-968

Transit

No disfigurement

No disfigurement

Method A

Acid Pollutants

No effect

No effect

ASTM D 1308, Proc. 6.2

10% Muriatic acid, 15 min.

No effect

No effect

ASTM D 1308, Proc. 6.2

20% sulfuric acid, 18 hrs.

<5 u. color change

<5 u. color change

AAMA 2605, TEST #7.7.3.3

Hunter E units

Hunter E units

70% nitric acid vapors, 30 min.

Acid Rain Test

10 cycles minimum

10 cycles minimum

KESTERNICH

No color change

No color change

Sulfur dioxide cyclic test

Accelerated Tests

Weatherometer, 3000 hrs. exposure

Acceptable (3)

Acceptable (3)

ASTM D 822, G 155

Atlas Weatherometer

Dew Cycle Weatherometer,

Acceptable (3)

Acceptable (3)

ASTM D 3361

500 hrs. exposure

Humidity, 100% relative

Passes 4000 hrs. (4)

Passes 1500 hrs. (4)

ASTM D 2247

humidity @ 95° F.

Salt Spray, 5% salt fog @ 95°F.

Passes 4000 hrs. (5)

Passes 1000 hrs. (5)

ASTM B 117 (NCCA 111-2)

Cyclic Salt Fog/UV Exposure Test

Passes 2016 hrs. (6)

Passes 2016 hrs. (6)

ASTM D 5894

Notes:

(1) Flexible to point of metal rupture without rupture of

coating.

(2) No loss of adhesion between coating and substrate

to point of metal rupture with 1/16" cross-hatch

scribe pattern through coating to bare metal.

(3) No objectionable chalking, color change or blistering.

(4) No No. 8 size blisters.

(5) Aluminum: none or few No. 8 size blisters, not more

than 1/16"avg. creep or tape off scribe.

Metallic Steel: none or few No. 8 size blisters, not

more than 1/8"avg. creep or tape off scribe.

(6) No blistering and no rating less than 5 per ASTM D 714; no

rusting per ASTM D 610; Rating of 6, less than 1.5 mm

creepage from scribe per ASTM D 1654

3. INSTALLATION

Installation shall be in accordance with standards established by

the Architectural Sheet Metal Community. Installer to comply with

all manufacturer's installation instructions as per project

requirements. Care should be taken during handling and

fabrication of materials to prevent bending, twisting, abrasion,

scratching, denting, etc. All cutting tools should be kept sharp,

properly dressed and aligned. If protective masking is utilized, it

must be removed immediately after installation.

4. AVAILABILITY AND COST

Availability: Normal orders for in stock items and colors are

ready for shipment within a 48 to 72 hour period. Custom

fabricated items are shipped within 7 to 10 working days.

Requests for custom colors need longer lead time. Products are

sold through Dealer/Distributor outlets.

Materials: Shipped F.O.B. ATAS Plant.

Cost: For specific cost and availability contact:

5. WARRANTY

ATAS coatings and base materials are warranted for film integrity

(color-fade-chalk) and rupture, cracking or perforating for a

thirty-year period from time of shipment, as per standard terms

and conditions noted in materials and finish warranty. An actual

copy of the warranty will be sent upon request. The product is to

be used as it is intended.

6. MAINTENANCE

ATAS coated materials are non-staining and virtually maintenance

free. Any surface residue is easily removed with conventional

cleaning solvents or detergents. Minor scratches may be touched

up with an air dry touch-up coating of the same color.

Conventional caulking compounds and sealants compatible with

the ATAS finish are acceptable for use in conjunction with the ATAS

coated materials.

7. TECHNICAL SERVICE

ATAS offers full in-house technical services, as well as a nationwide

network of field service representatives.

Allentown, PA 18106

Ph: 610-395-8445 800-468-1441

Fax: 610-395-9342

Mesa, AZ 85204

Ph: 480-558-7210 800-879-8382

Fax: 480-558-7217

Maryville, TN 37801

Ph: 800-468-1441

ATAS International, Inc.

www.atas.com • email: [email protected]

LAT700