6 battery installation – Alpha Technologies Cordex CXPS-D 48-2500_5000A User Manual

Page 38

-5HY%

5.6 Battery

Installation

This information is provided as a guideline and is not meant to imply that batteries are part of this power system.

:$51,1*

)ROORZEDWWHU\PDQXIDFWXUHU¶VVDIHW\UHFRPPHQGDWLRQVZKHQZRUNLQJDURXQGEDWWHU\

V\VWHPVDQGUHYLHZWKHVDIHW\LQVWUXFWLRQVSURYLGHGLQWKLVPDQXDO

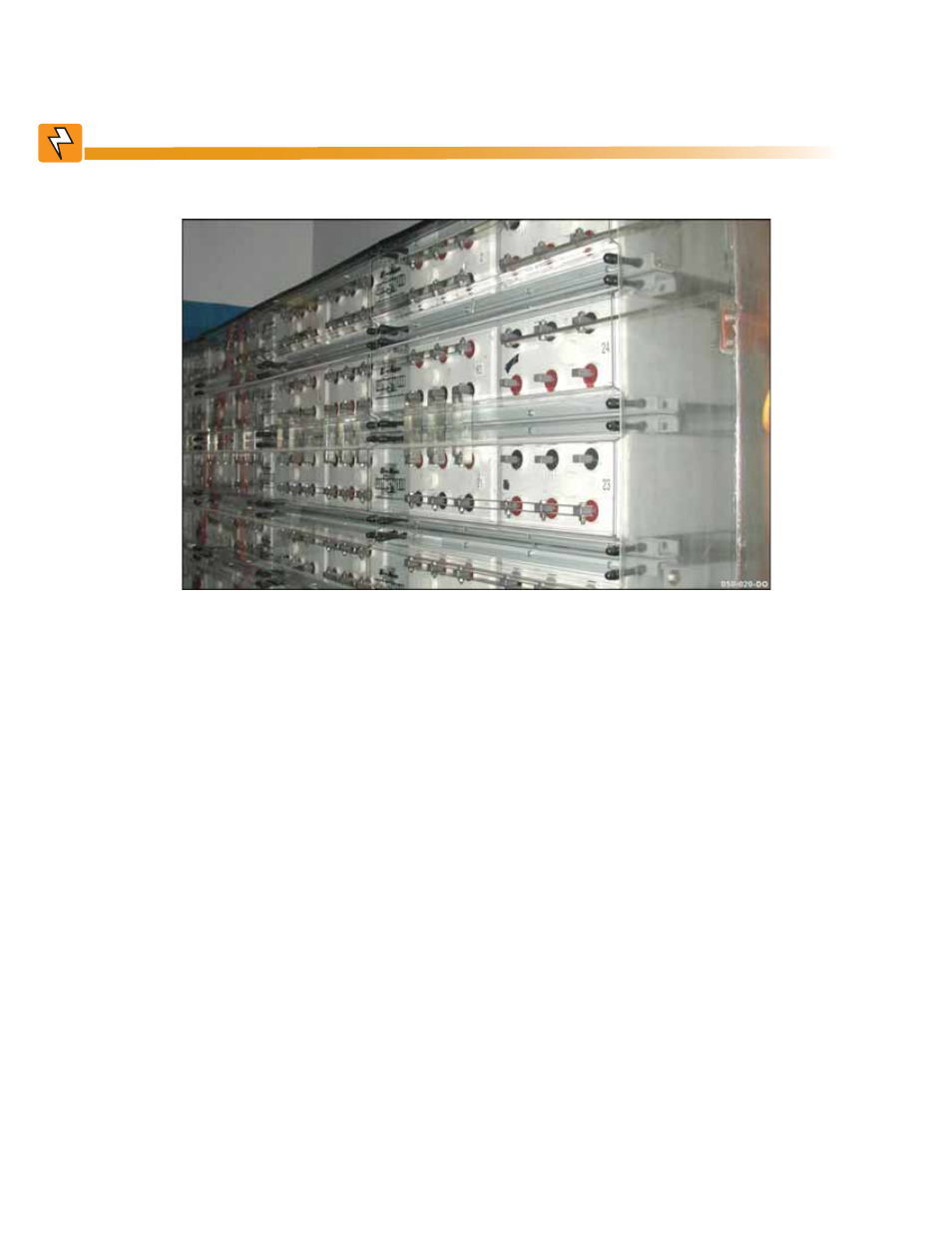

)LJXUH ² %DWWHU\LQVWDOODWLRQ

5.6.1 Preparation/Mounting

Batteries should be located in a temperature-controlled environment. The temperature should be regulated at

approx. 25°C (77°F). Significantly lower temperatures reduce performance and higher temperatures decrease life

expectancy.

Before assembly, clean cells (where applicable) as per the battery manufacturer's recommendations. First neu-

tralize any acid with a baking soda and water solution. Then wipe the cells with clean water.

5.6.2 Installation of External Batteries

Verify that all battery breakers, DC circuit breakers, and fuses on the distribution panels are either in the OFF

position or removed.

Use a corrosion-inhibiting agent such as NO-OX or NCP-2 on all battery terminal connections.

1. Assemble battery rack (if required) and the cells or mono-blocks as per the installation instructions supplied

with the batteries.

2. Ensure that the battery output cabling will reach the [+] and [–] terminals of the series battery string and that

the batteries are oriented correctly for easy installation of the inter-unit “series” connectors.

3. Remove any no-oxide “A” grease from battery terminals.

4. Burnish terminal posts with a non-metallic brush, polishing pad or 3M-type scotch pad.

5. Apply a light coating of no-oxide “A” grease to the terminal posts.

6. If lead plated inter-unit connectors are used, they should also be burnished and no-oxide “A” grease applied

as above. Install the inter-unit connectors.

7. After all battery connections are completed, torque per battery specifications (typically 100 in-lbs).

8. See system startup procedure before connecting batteries online.