Alpha Technologies Te41, 24V User Manual

Page 31

Argus Technologies Ltd.

057-102-C0 Rev B WC

Printed in Canada. © 2009 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved.

Page 19 of 26

7.2

Installation of Batteries in Argus Tempest Power Systems

Verify that all battery breakers, DC circuit breakers, and fuses on the distribution panels are either

in the OFF position or removed. For each of the following steps, verify that the rubber terminal

caps / plastic covers are on and are completely covering the positive and negative terminal

connections.

Use a corrosion-inhibiting agent, such as NO-OX-ID “A”

¥, on all battery terminal connections.

1.

Check the battery block voltage (typically >12.6V).

2.

Unplug Anderson connectors on all battery string cables to disconnect DC output bus bars from system.

3.

Slide the battery blocks onto the battery trays starting at the bottom (four per tray) – see previous photos.

NOTE: The enclosure must be mounted before installation of the bottom tray of batteries may be completed.

4.

Ensure that the battery output cabling will reach the [+] and [–] terminals of the series battery string and that

the batteries are oriented correctly for easy installation of the inter-unit “series” connectors.

5.

Remove any NO-OX-ID “A”

¥ grease from battery terminals.

6.

Burnish terminal posts with a non-metallic brush, polishing pad or 3M Scotch Brite

¥ scouring pad.

7.

Apply a light coating of NO-OX-ID “A”

¥ grease to the terminal posts.

8.

If lead plated inter-unit connectors are used, they should also be burnished and NO-OX-ID “A”

¥ grease

applied as above. Install the inter-unit connectors.

9.

Connect the batteries to the pre-installed cables.

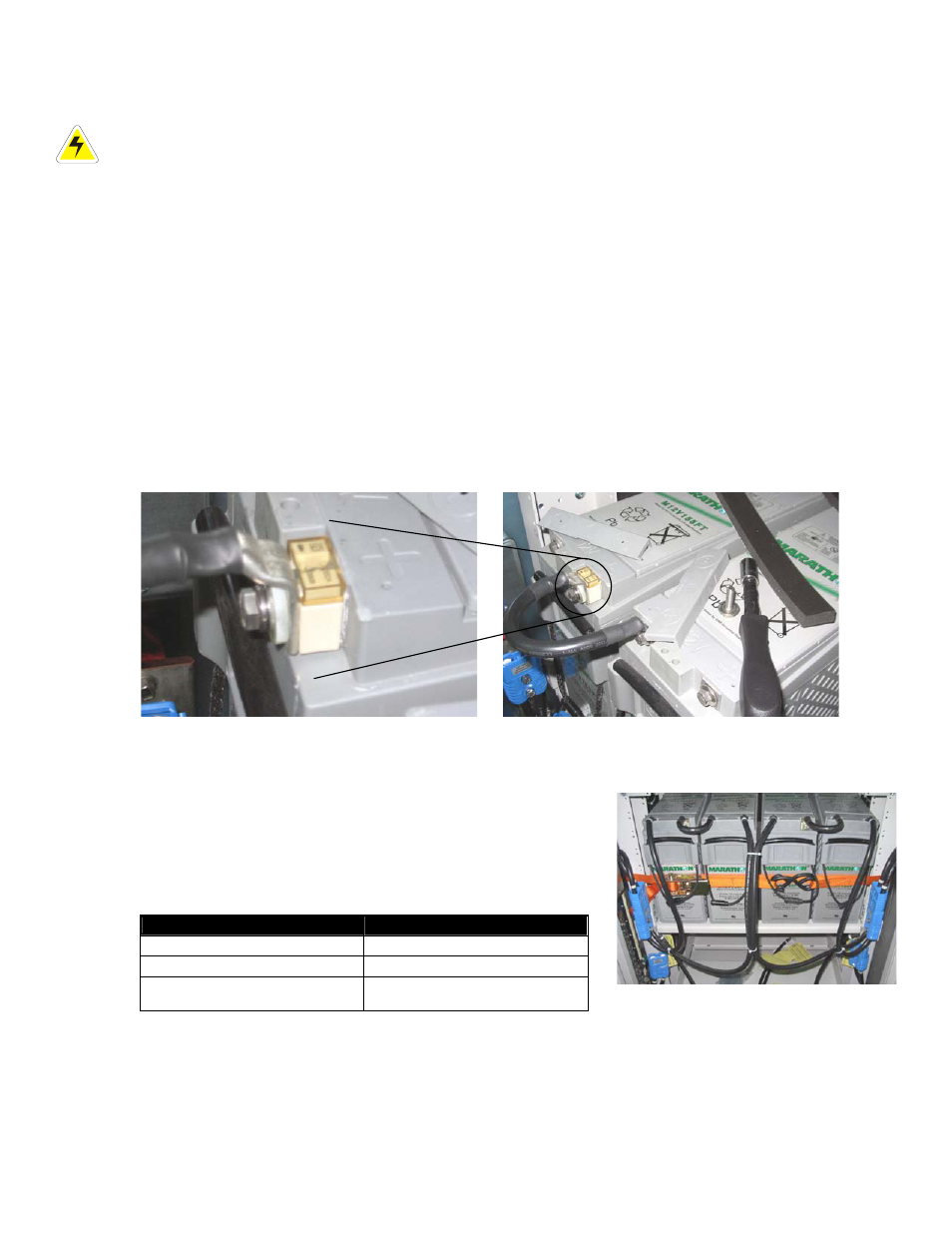

10. Install in-line battery fuse on one battery terminal inter-unit connector per string (two fuses per shelf for a 24V

configuration); for example:

NOTE: Sequence: battery terminal, fuse, inter-unit connector, insulating shoulder washer, flat/split washer, and bolt.

Mounting bolt torque is 8.4Nm +/- 0.5Nm maximum. Exceeding this value may damage the insulating shoulder

washer or fuse or both. Refer to battery fuse kit instructions for the specific batteries used.

11. Install battery temperature probe to the negative terminal of two

center batteries, one on each tier, in the same enclosure.

12. Repeat the above installation procedure for each shelf and battery

string.

13. After all battery connections are completed, torque per battery

specifications; for example:

Description

Recommended Torque Value

GNB battery bolts

100 in-lbs

East Penn Deka battery bolts

45 in-lbs

Battery in-line fuse

75 in-lbs. or battery torque

(whichever is less)

Sample battery cabling

(Photo is for reference only – subject to

installation requirements)

Table B–Sample torque specifications

14. Verify polarity and voltage at each battery cable (Anderson connector contacts). Do not connect yet!

NOTE: See system startup procedure before connecting batteries online.

After assembly, batteries should be numbered and “as received” readings should be taken, such as, battery

voltage and temperature. Refer to manufacturer's literature for guidelines.

See following table for typical maintenance report.