Field calibration procedure – Franklin Fueling Systems T5 Series Density Measurement Option Installation User Manual

Page 6

6

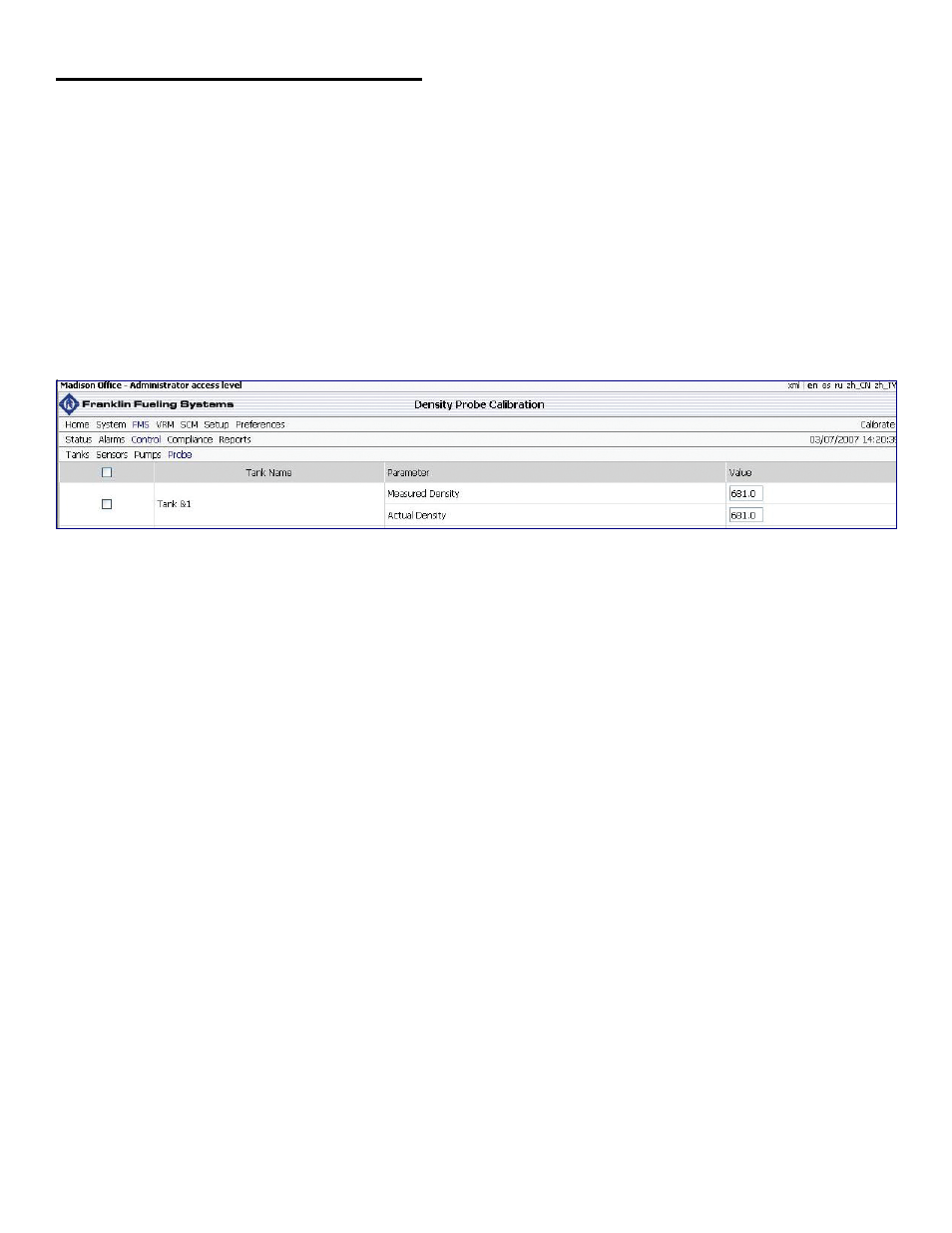

Field Calibration Procedure

Over time a float’s weight can change due to sediment deposits, which can lead to systematically inaccurate readings.

These inaccuracies can be minimized with the help of periodic system calibration.

Calibration can be conducted using comparison readings from the ATG and comparing it to the density obtained using a

reference densitometer. In order to do this, it is necessary to take a product sample from the level near the density float.

Before taking a sample record the ATG density reading ‘Measured Density’ and the temperature of the product. Measur-

ing density of the sample with a reference densitometer you will obtain ‘Actual Density’ and ‘Actual Temperature’. Set the

same temperature for the Actual and Measured.

If the readings are equal, Calibration is not necessary.

•

If the difference between the Measured Density and the Actual Density is more than 5 kg/m

•

3

, the floats should be re-

moved, cleaned, inspected and retested.

If the difference between readings is more than 10 kg/m

•

3

after the floats have been cleaned, they should be replaced.

Both measurements should be entered into the system, pressing the “Calibrate” button will recalculate density calibration

constant and make all necessary corrections.

Important: If measured density and real density differ greatly, the probe needs to be extracted and inspected.

Make sure that there is no debris on top of the floats. Clean if necessary.