Data sheet – GE Industrial Solutions JRCW016A0R Orca Series User Manual

Page 6

GE

Data Sheet

JRCW016A0R Orca Series; DC-DC Converter Power Modules

36–75 Vdc Input; 28.0Vdc Output; 16Adc Output

November 20, 2013

©2012 General Electric Company. All rights reserved.

Page 6

Test Configurations

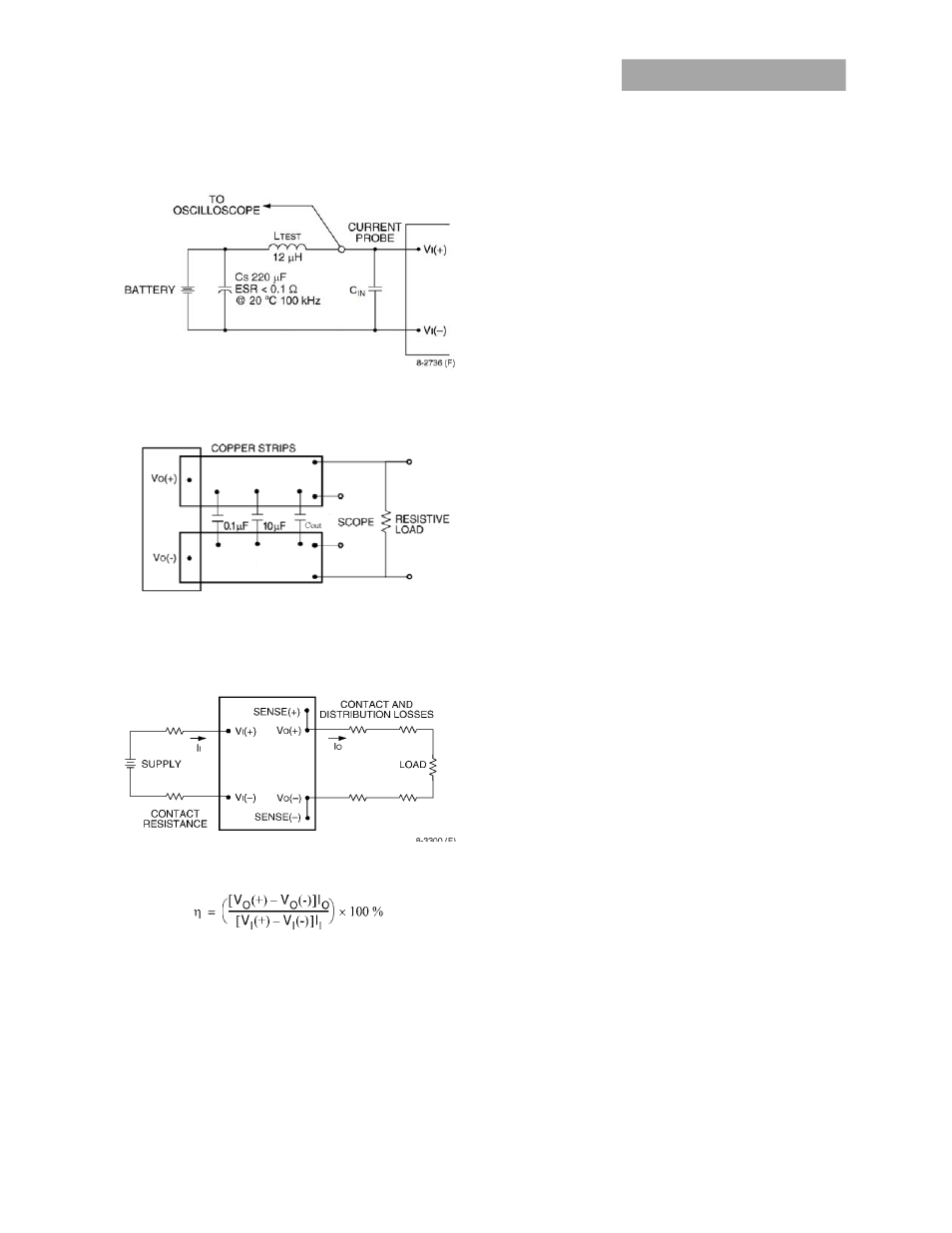

Note: Measure the input reflected-ripple current with a simulated

source inductance (LTEST) of 12 µH. Capacitor CS offsets possible

battery impedance. Measure the current, as shown above.

Figure 7. Input Reflected Ripple Current Test Setup.

Note: Use a Cout (470 µF Low ESR aluminum or tantalum capacitor

typical), a 0.1 µF ceramic capacitor and a 10 µF ceramic capacitor,

and Scope measurement should be made using a BNC socket.

Position the load between 51 mm and 76 mm (2 in. and 3 in.) from the

module.

Figure 8. Output Ripple and Noise Test Setup.

Note: All measurements are taken at the module terminals. When

socketing, place Kelvin connections at module terminals to avoid

measurement errors due to socket contact resistance.

Figure 9. Output Voltage and Efficiency Test Setup.

Design Considerations

Input Source Impedance

The power module should be connected to a low

ac-impedance source. A highly inductive source impedance

can affect the stability of the power module. For the test

configuration in Figure 7, a 470μF Low ESR aluminum

capacitor, C

IN

, mounted close to the power module helps

ensure the stability of the unit. Consult the factory for further

application guidelines.

Output Capacitance

The JRCW016A0R power module requires a minimum output

capacitance of 440µF Low ESR aluminum capacitor, C

out

to

ensure stable operation over the full range of load and line

conditions, see Figure 8. If the ambient temperature is under -

20C, it is required to use at least 3 pcs of minimum capacitors

in parallel. In general, the process of determining the

acceptable values of output capacitance and ESR is complex

and is load-dependent.

Safety Considerations

For safety-agency approval of the system in which the power

module is used, the power module must be installed in

compliance with the spacing and separation requirements of

the end-use safety agency standard, i.e., UL 60950-1, 2nd Ed.,

CSA No. 60950-1 2

nd

Ed., and VDE0805-1 EN60950-1, 2nd Ed.

For end products connected to –48V dc, or –60Vdc nominal

DC MAINS (i.e. central office dc battery plant), no further fault

testing is required. *Note: -60V dc nominal battery plants are

not available in the U.S. or Canada.

For all input voltages, other than DC MAINS, where the input

voltage is less than 60V dc, if the input meets all of the

requirements for SELV, then:

The output may be considered SELV. Output voltages will

remain within SELV limits even with internally-generated

non-SELV voltages. Single component failure and fault

tests were performed in the power converters.

One pole of the input and one pole of the output are to

be grounded, or both circuits are to be kept floating, to

maintain the output voltage to ground voltage within ELV

or SELV limits. However, SELV will not be maintained if

V

I

(+) and V

O

(+) are grounded simultaneously.