Data sheet, Thermal considerations – GE Industrial Solutions JRCW016A0R Orca Series User Manual

Page 10

GE

Data Sheet

JRCW016A0R Orca Series; DC-DC Converter Power Modules

36–75 Vdc Input; 28.0Vdc Output; 16Adc Output

November 20, 2013

©2012 General Electric Company. All rights reserved.

Page 10

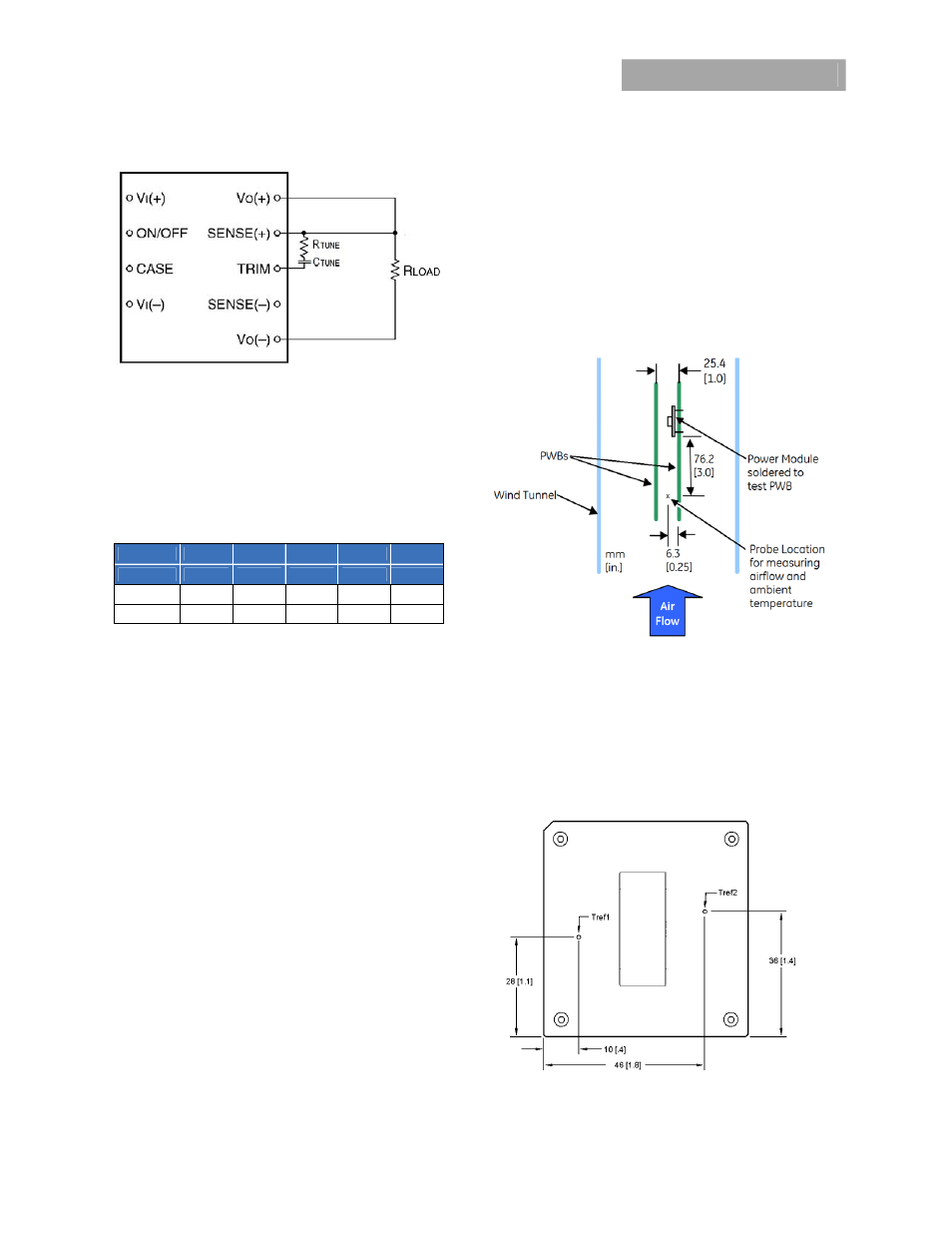

Figure 16. Circuit diagram showing connection of R

TUNE

and

C

TUNE

to tune the control loop of the module.

Table 1 shows the recommended values of R

TUNE

and C

TUNE

for

different values of ceramic output capacitors up to 8000 F

that might be needed for an

application to meet output ripple and noise requirements.

Table 1. General recommended values of of R

TUNE

and C

TUNE

for V

out

=28V and various external ceramic capacitor

combinations.

C

out

(µF)

1100

2200

4400

6600

8800

ESR (mΩ)

60

30

15

10

7.5

R

TUNE

12k 4.7k 1.8k 820 390

C

TUNE

220nF 220nF 220nF 220nF 220nF

Please contact your GE technical representative to obtain

more details of this feature as well as for guidelines on how to

select the right value of external R-C to tune the module for

best transient performance and stable operation for other

output capacitance values.

Over Temperature Protection

The JRCW016A0R module provides a non-latching over

temperature protection. A temperature sensor monitors the

operating temperature of the converter. If the reference

temperature, T

REF 1

, (see Figure 17) exceeds a threshold of 115

ºC (typical), the converter will shut down and disable the

output. When the base plate temperature has decreased by

approximately 20 ºC the converter will automatically restart.

The module can be restarted by cycling the dc input power for

at least one second or by toggling the remote on/off signal for

at least one second.

Thermal Considerations

The power modules operate in a variety of thermal

environments; however, sufficient cooling should be provided

to help ensure reliable operation of the unit. Heat-dissipating

components inside the unit are thermally coupled to the case.

Heat is removed by conduction, convection, and radiation to

the surrounding environment. Proper cooling can be verified

by measuring the case temperature. Peak temperature (T

REF

)

occurs at the position indicated in Figure 17.

Considerations include ambient temperature, airflow, module

power dissipation, and the need for increased reliability. A

reduction in the operating temperature of the module will

result in an increase in reliability.

The thermal data presented here is based on physical

measurements taken in a wind tunnel, using automated

thermo-couple instrumentation to monitor key component

temperatures: FETs, diodes, control ICs, magnetic cores,

ceramic capacitors, opto-isolators, and module pwb

conductors, while controlling the ambient airflow rate and

temperature. For a given airflow and ambient temperature,

the module output power is increased, until one (or more) of

the components reaches its maximum derated operating

temperature, as defined in IPC-9592. This procedure is then

repeated for a different airflow or ambient temperature until a

family of module output derating curves is obtained.

Heat-dissipating components inside the unit are thermally

coupled to the case. Heat is removed by conduction,

convection, and radiation to the surrounding environment.

For reliable operation this temperature should not

exceed 100ºC at either T

REF 1

or T

REF 2

for applications using

forced convection airflow or cold plate applications. The

output power of the module should not exceed the rated

power for the module as listed in the ordering Information

table. Although the maximum T

REF

temperature of the power

modules is discussed above, you can limit this temperature to

a lower value for extremely high reliability.

Figure 17.

Case (T

REF

) Temperature Measurement Location

(top view).