Module derating, Figure 61. experimental test setup, Layout considerations – GE Industrial Solutions LC-LW015-Series User Manual

Page 21: E 58): p, Thermal considerations, Lineage power 21, Continued), 25 °c

Lineage Power

21

Data Sheet

March 27, 2008

18 Vdc to 36 Vdc or 36 Vdc to 75 Vdc Inputs, 10 W and 15 W

LC/LW010- and LC/LW015-Series Power Modules:

Thermal Considerations

(continued)

8-1380(C)

Figure 58. LW010A, B, C Typical Power Dissipation

vs. Normalized Output Current at

T

C

= 25 °C

8-1816(C)

Figure 59. LW010F Typical Power Dissipation vs.

Output Current at T

C

= 25 °C

8-1817(C)

Figure 60. LW010AJ, BK, CL Typical Power

Dissipation vs. Normalized Output

Current at T

C

= 25 °C

Module Derating

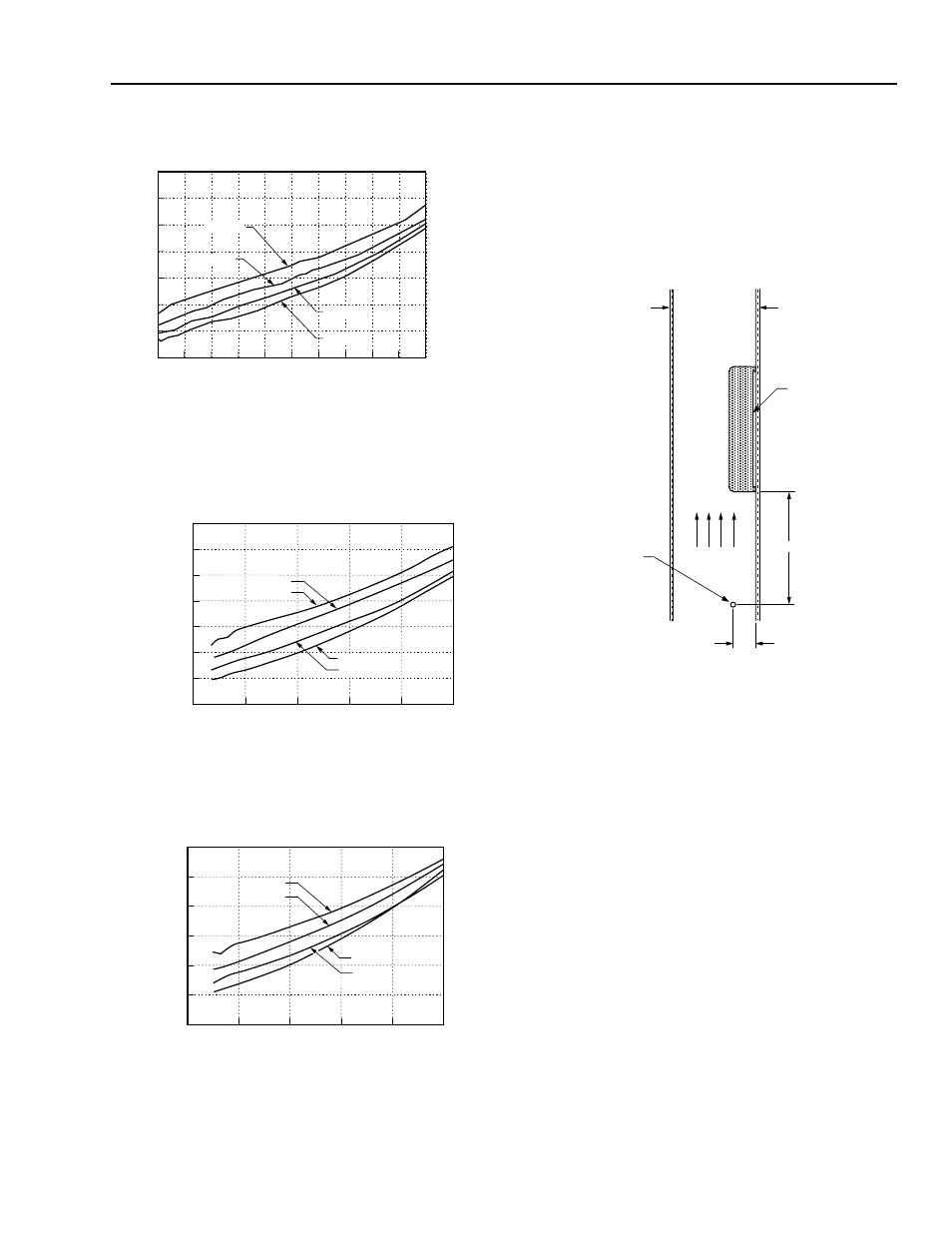

The derating curves in Figures 43 through 45 were

determined by measurements obtained in an experi-

mental apparatus shown in Figure 61. Note that the

module and the printed-wiring board (PWB) that it is

mounted on are both vertically oriented. The passage

has a rectangular cross section.

8-1126(C).d

Note: Dimensions are in millimeters and (inches).

Figure 61. Experimental Test Setup

Layout Considerations

Copper paths must not be routed beneath the power

module standoffs.

0.1

0.2

0.3

0.4

0.5

0.6

0.0

2.5

NORMALIZED OUTPUT CURRENT (I

O

/I

O

, max)

1.5

1.0

0.5

2.0

PO

WER DISSIP

A

TION,

P

D

(W)

V

I

= 75 V

3.5

0.7

0.8

0.9

1.0

0.0

V

I

= 48 V

V

I

= 36 V

3.0

V

I

= 60 V

1.0

0.0

2.0

3.0

3.5

0.5

1.5

2.5

0.5

1.0

1.5

2.0

2.5

0.0

OUTPUT CURRENT, I

O

(A)

V

I

= 36 V

V

I

= 48 V

PO

WER DISSIP

A

TION,

P

D

(W)

V

I

= 60 V

V

I

= 75 V

0.2

0.4

0.6

0.8

1.0

0.0

2.5

1.5

1.0

2.0

0.0

3.0

0.5

NORMALIZED OUTPUT CURRENT,

I

O1

= I

O2

[(I

O1

+ I

O2

)/(I

O1

,

max

+ I

O2

,

max

)]

V

I

= 36 V

V

I

= 48 V

V

I

= 60 V

PO

WER DISSIP

A

TION,

P

D

(W)

V

I

= 75 V

AIR VELOCITY

AND AMBIENT

TEMPERATURE

MEASURED

BELOW THE

MODULE

AIRFLOW

13 (0.5)

FACING PWB

MODULE

76 (3.0)

PWB