20a analog microdlynx, Non-isolated dc-dc power modules, Data sheet – GE Industrial Solutions 20A Analog MicroDLynx User Manual

Page 18: Shock and vibration

GE

Data Sheet

20A Analog MicroDLynx

TM

: Non-Isolated DC-DC Power Modules

3Vdc –14.4Vdc input; 0.45Vdc to 5.5Vdc output; 20A Output Current

April 24, 2013

©2012 General Electric Company. All rights reserved.

Page 18

Shock and Vibration

The ruggedized (-D version) of the modules are designed to

withstand elevated levels of shock and vibration to be able to

operate in harsh environments. The ruggedized modules

have been successfully tested to the following conditions:

Non operating random vibration:

Random vibration tests conducted at 25C, 10 to 2000Hz, for

30 minutes each level, starting from 30Grms (Z axis) and up to

50Grms (Z axis). The units were then subjected to two more

tests of 50Grms at 30 minutes each for a total of 90 minutes.

Operating shock to 40G per Mil Std. 810F, Method 516.4

Procedure I:

The modules were tested in opposing directions along each

of three orthogonal axes, with waveform and amplitude of

the shock impulse characteristics as follows:

All shocks were half sine pulses, 11 milliseconds (ms) in

duration in all 3 axes.

Units were tested to the Functional Shock Test of MIL-STD-

810, Method 516.4, Procedure I - Figure 516.4-4. A shock

magnitude of 40G was utilized. The operational units were

subjected to three shocks in each direction along three axes

for a total of eighteen shocks.

Operating vibration per Mil Std 810F, Method 514.5

Procedure I:

The ruggedized (-D version) modules are designed and

tested to vibration levels as outlined in MIL-STD-810F,

Method 514.5, and Procedure 1, using the Power Spectral

Density (PSD) profiles as shown in Table 7 and Table 8 for all

axes. Full compliance with performance specifications was

required during the performance test. No damage was

allowed to the module and full compliance to performance

specifications was required when the endurance

environment was removed. The module was tested per MIL-

STD-810, Method 514.5, Procedure I, for functional

(performance) and endurance random vibration using the

performance and endurance levels shown in Table 7 and

Table 8 for all axes. The performance test has been split,

with one half accomplished before the endurance test and

one half after the endurance test (in each axis). The duration

of the performance test was at least 16 minutes total per

axis and at least 120 minutes total per axis for the

endurance test. The endurance test period was 2 hours

minimum per axis.

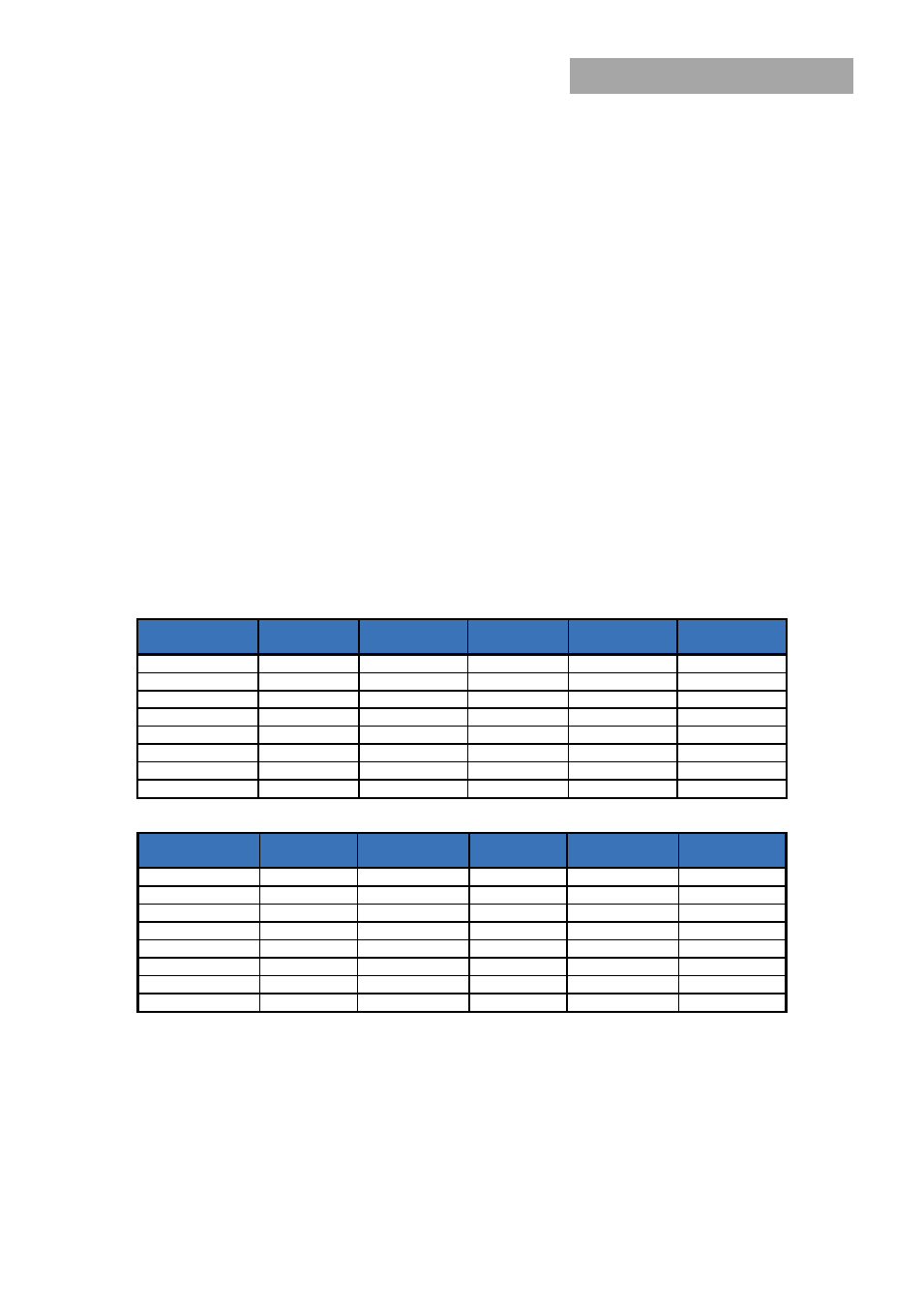

Table 7: Performance Vibration Qualification - All Axes

Frequency (Hz)

PSD Level

(G2/Hz)

Frequency (Hz)

PSD Level

(G2/Hz)

Frequency (Hz)

PSD Level

(G2/Hz)

10

1.14E-03

170

2.54E-03

690

1.03E-03

30

5.96E-03

230

3.70E-03

800

7.29E-03

40

9.53E-04

290

7.99E-04

890

1.00E-03

50

2.08E-03

340

1.12E-02

1070

2.67E-03

90

2.08E-03

370

1.12E-02

1240

1.08E-03

110

7.05E-04

430

8.84E-04

1550

2.54E-03

130

5.00E-03

490

1.54E-03

1780

2.88E-03

140

8.20E-04

560

5.62E-04

2000

5.62E-04

Table 8: Endurance Vibration Qualification - All Axes

Frequency (Hz)

PSD Level

(G2/Hz)

Frequency (Hz)

PSD Level

(G2/Hz)

Frequency (Hz)

PSD Level

(G2/Hz)

10

0.00803

170

0.01795

690

0.00727

30

0.04216

230

0.02616

800

0.05155

40

0.00674

290

0.00565

890

0.00709

50

0.01468

340

0.07901

1070

0.01887

90

0.01468

370

0.07901

1240

0.00764

110

0.00498

430

0.00625

1550

0.01795

130

0.03536

490

0.01086

1780

0.02035

140

0.0058

560

0.00398

2000

0.00398