Shhn000a3 series; dc-dc converter power modules, Datasheet, Surface mount information (continued) – GE Industrial Solutions SHHN000A3 HAMMERHEAD Series User Manual

Page 11

GE

Datasheet

SHHN000A3 Series; DC-DC Converter Power Modules

9Vdc – 36Vdc input; +15V, -15V Dual Output, 0.3A 9W Output

December 6, 2013

©2013 General Electric Corporation.

All rights reserved.

Page 11

MAX TEM

P

SO

LD

ER (

°C)

TIME LIMIT (S)

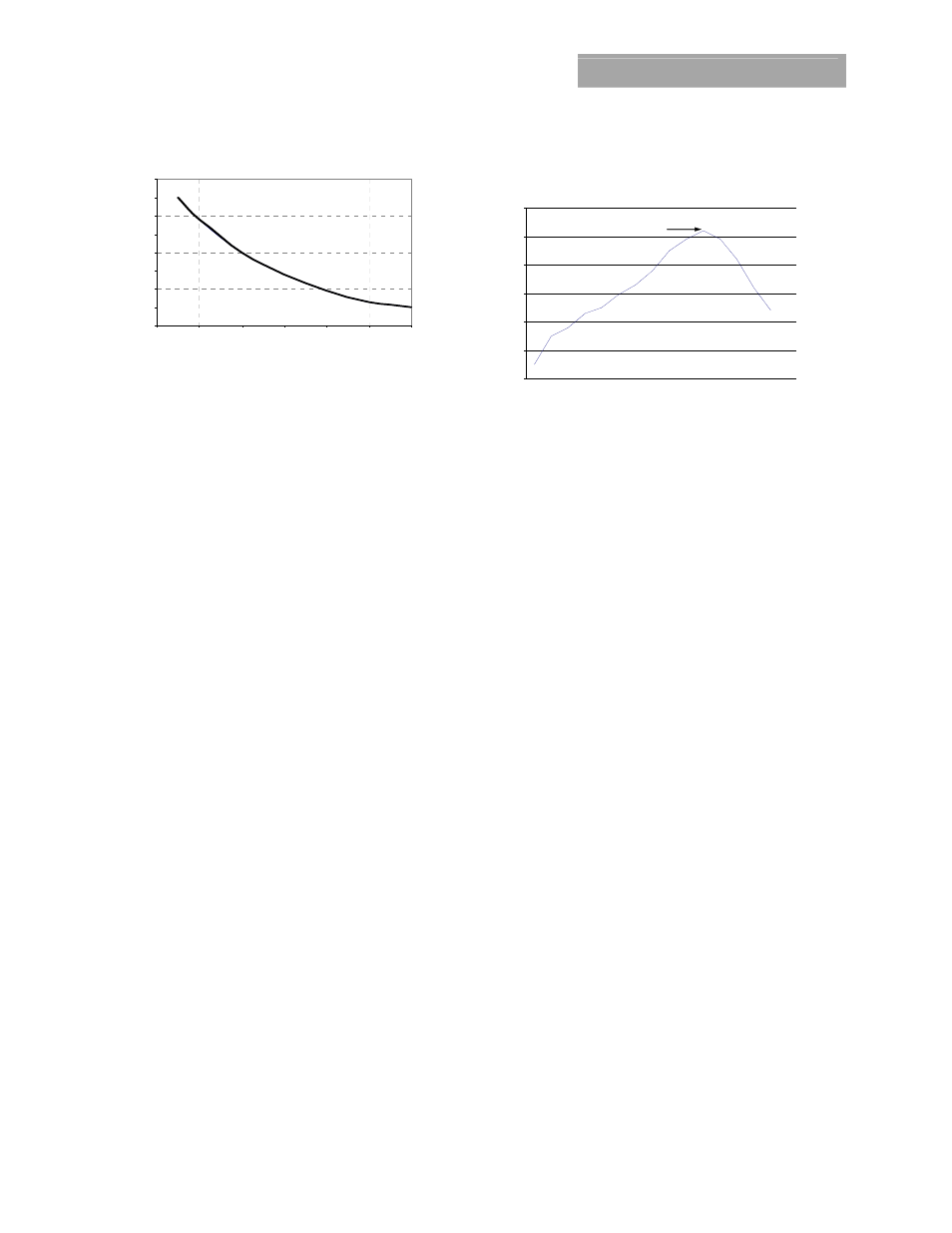

Figure 21. Time Limit, T

lim

, Curve Above 205

o

C Reflow .

Lead Free Soldering

The –Z version SMT modules of the SHHN000A3 series are

lead-free (Pb-free) and RoHS compliant and are compatible in

a

Pb-free soldering process. Failure to observe the instructions

below may result in the failure of or cause damage to the

modules and can adversely affect long-term reliability.

Pb-free Reflow Profile

Power Systems will comply with J-STD-020 Rev. D

(Moisture/Reflow Sensitivity Classification for Nonhermetic

Solid State Surface Mount Devices)

for both Pb-free solder profiles and MSL classification

procedures. This standard provides a recommended forced-

air-convection reflow profile based on the volume and

thickness of the package (table 4-2). The suggested Pb-free

solder paste is Sn/Ag/Cu (SAC). The recommended linear reflow

profile using Sn/Ag/Cu solder is shown in Figure 22.

Surface Mount Information (continued)

Figure 22. Recommended linear reflow profile using

Sn/Ag/Cu solder.

MSL Rating

The SHHN000A3 series SMT modules have a MSL rating of 2a.

Storage and Handling

The recommended storage environment and handling

procedures for moisture-sensitive surface mount packages is

detailed in J-STD-033 Rev. A (Handling, Packing, Shipping and

Use of Moisture/Reflow Sensitive Surface Mount Devices).

Moisture barrier bags (MBB) with desiccant are required for

MSL ratings of 2 or greater. These sealed packages should not

be broken until time of use. Once the original package is

broken, the floor life of the product at conditions of

≤ 30°C and

60% relative humidity varies according to the MSL rating (see

J-STD-033A). The shelf life for dry packed SMT packages will be

a minimum of 12 months from the bag seal date, when stored

at the following conditions: < 40° C, < 90% relative humidity.

Post Solder Cleaning and Drying Considerations

Post solder cleaning is usually the final circuit-board assembly

process prior to electrical board testing. The result of

inadequate cleaning and drying can affect both the reliability

of a power module and the testability of the finished

circuit-board assembly. For guidance on appropriate soldering,

cleaning and drying procedures, refer to GE Board Mounted

Power Modules: Soldering and Cleaning Application Note

(AP01-056EPS).

200

205

210

215

220

225

230

235

240

0

10

20

30

40

50

60

Per J-STD-020 Rev. D

0

50

100

150

200

250

300

Reflow Time (Seconds)

Ref

lo

w

T

em

p (°

C)

Heating Zone

1°C/Second

Peak Temp 260°C

* Min. Time Above 235°C

15 Seconds

*Time Above 217°C

60 Seconds

Cooling

Zone