Installation guide, Troubleshooting, Aspmeter – GE Industrial Solutions ASPMETER Install User Manual

Page 10

TM

ASPMETER

INSTALLATION GUIDE

Z206024-0B

PAGE 10

©2011 For technical support please contact

10111

DET-756

our GE tech support team at 1-800-GE-1-STOP (1-800-431-7867)

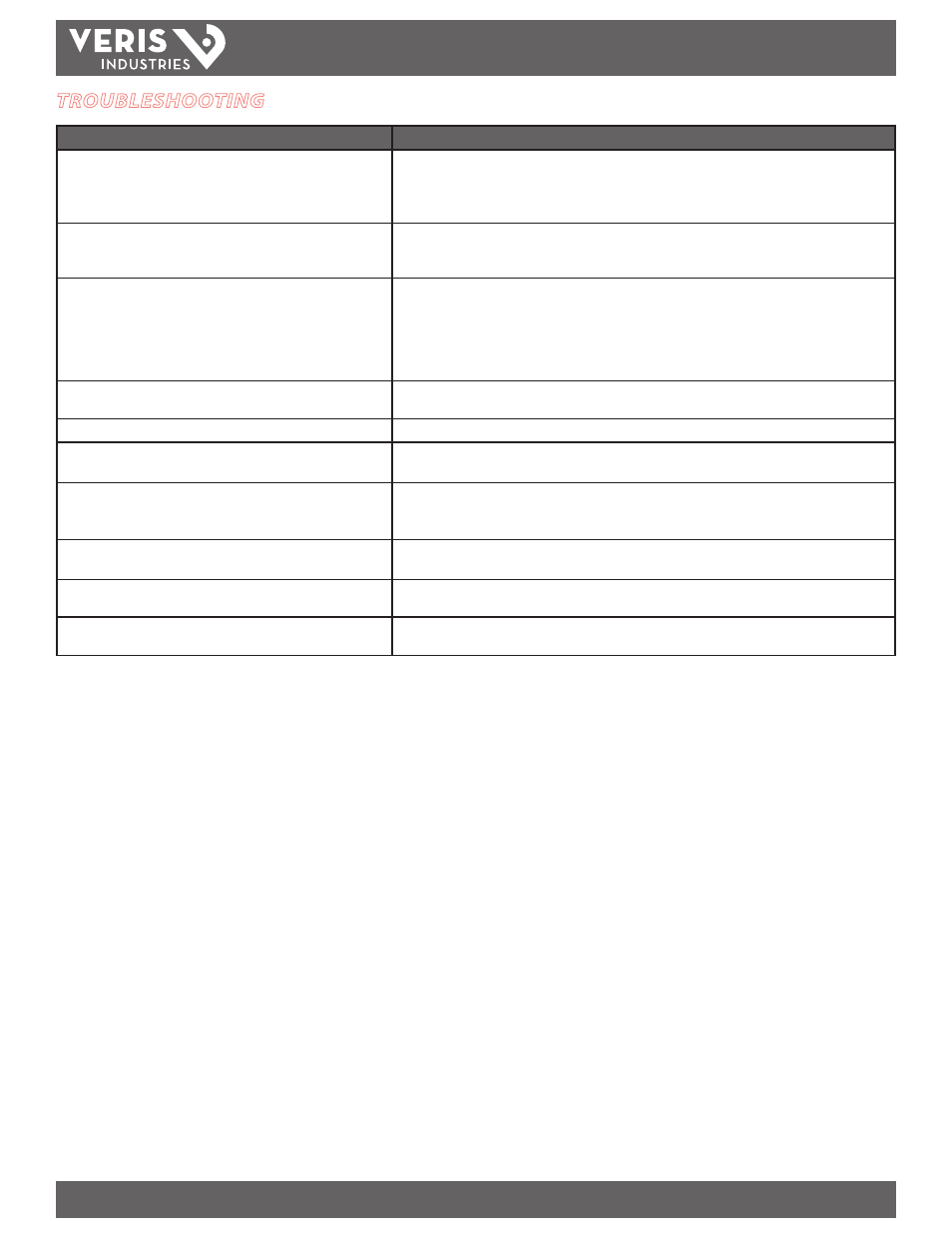

TROUBLESHOOTING

Problem

Solution

Product is not communicating over Modbus daisy chain

• Check the unit Modbus address to ensure that each device on the daisy chain has a unique address.

• Check Parity.

• Check the communications wiring.

• Check that the daisy chain is properly terminated.

RX LED is solid

• Check for reversed polarity on Modbus comms.

• Check for sufficient biasing on the Modbus bus. Modbus physical specification calls for 450-650Ohm biasing.

This is usually provided by the master.

The main board has a fast flashing amber light

• Check that the 1A and 1B CT strips are connected to the left top and left bottom ribbon cable connections; 2A

and 2B must be connected to the right top and right bottom ribbon cable connections (see illustrations in the

product install).

• Verify ribbon cable connectors are inserted in the correct orientation.

• If cables are correct, reset main board to re-initialize product.

• Verify serial number on strips matches serial number on main board.

The main board has a slow flashing amber light

• One or more channels is clipping, this can be caused by a signal greater than 100 A or 277 V L-N, or by a signal

with high THD near the gain stage switching points (1.5 A and 10 A).

The main board has a flashing green light

• Everything is wired properly and the main board has power.

The main board is a flashing or solid red light

• Light may be red briefly while device powers up.

• If light is red for more the 60 sec. device has encountered an error. Contact technical support.

Power factor reading is not as expected

• Verify voltage taps are connected in appropriate phase rotation.

• Verify strip configuration register matches actual strip installation.

• Verify phase rotation of breakers (firmware rev. 1.012 or higher allows for custom rotation if needed).

Current reading is not as expected, or reading is on different CT number

than expected

• Verify strip configuration register matches actual strip installation.

• Verify ribbon cable is fully seated and in the correct orientation.

Current is reading zero, even when small currents are still flowing through

circuit

• The product cuts off at 50 mA, and will set the reporting register to 0 mA for currents near or below this range.

E3x Config Tool returns Modbus error on read/write

• Verify using the latest release of E3x Config Tool as older versions may not support all features in current product

firmware. Latest version is available on our website http://www.veris.com/modbus.aspx