Installing spectra series™ busway – GE Industrial Solutions Spectra II Series Plug-in and Feeder Busway with BlueCoat Epoxy Insulation System User Manual

Page 5

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing Spectra Series Busway

3

Installing Spectra Series™ Busway

Storage Precautions

Before storing, unpack sufficiently to make a

check of the busway for possible concealed

damage resulting from shipping and handling. If

damage has occurred, notify the shipper

immediately. If the busway is free of damage,

restore the packing until ready for installation.

Store indoors in a clean, dry area, preferably close

to the installation points.

Protect the busway from mechanical damage and

any contact with or exposure to corrosive fumes,

liquids, salts, or concrete.

Failure to store and protect the busway properly

can cause serious damage and will void the

warranty.

NOTE: No busway, including outdoor rated, is

weatherproof until completely and properly

installed.

NOTE: Aucune canalisation pour barres omnibus,

incluant celles classées pour l'extérieur, n'est à

l'épreuve de l'eau jusqu'à ce qu'elle soit installée

complètement et correctement.

Pre-Installation Procedure

When possible, deliver the busway to its

installation location before unpacking. Large

labels on each shipping carton or crate designate

the items contained. Additionally, each busway

piece is identified with an item number label.

Inspect each busway piece for possible damage

or contamination. Contact surfaces must be clean.

However, do not attempt to polish tarnished

contact surfaces.

Check to ensure that joint insulators are not

damaged or cracked and are firmly in place.

Megohm test each piece before installation.

Installation of Spectra Series Busway

Establish the bus bar phase sequence (Ø side is

labeled) to determine how the busway is to be

installed, so that correct phasing is maintained

throughout the system. Note that phase

transposition lengths, when furnished, may

relocate the Ø to the opposite side of a busway

run.

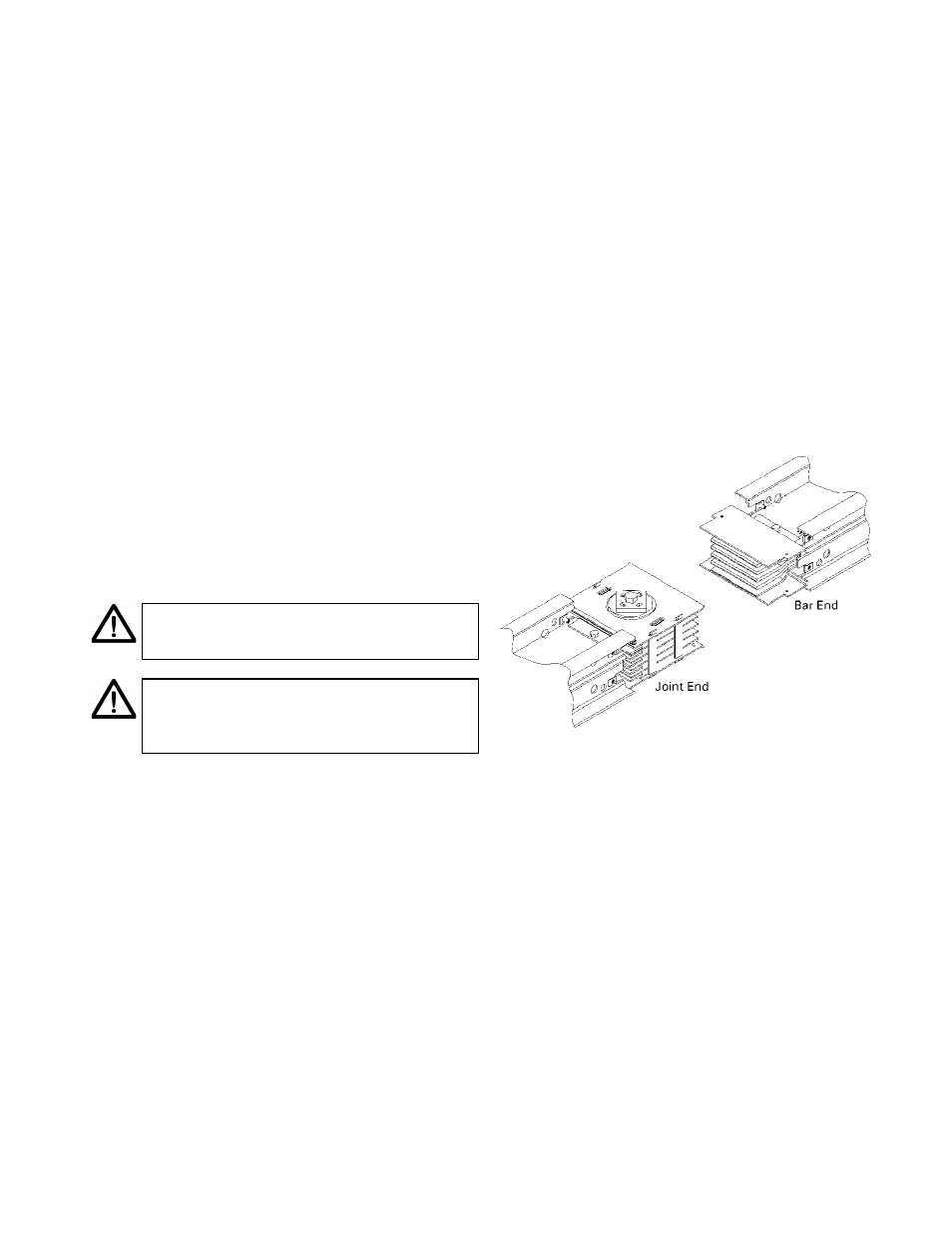

Each busway piece has a ―bar end‖ and a ―joint

end,‖ as illustrated in Figure 1. Normally the

busway is oriented end for end with bar ends

pointing away from the source. Also, the ø side

should be oriented down for horizontal plug-in

applications.

Figure 1. The bar end and joint end of the busway.

In vertical riser installations, it is easier to lower

the busway into place than it is to raise it.

If installation drawings have been furnished,

information regarding the orientation of the

busway and location of the ø side, as well as other

pertinent data, will be furnished. These drawings

should be followed carefully to ensure a proper

busway system.

Where to Start

Start the installation, if at all possible, at the most

critical point, such as a main feed box,

switchboard or switchgear, elbow, or other critical

fitting or termination.