GE Industrial Solutions Spectra II Series Plug-in and Feeder Busway with BlueCoat Epoxy Insulation System User Manual

Page 12

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing and Removing Spectra Busway Plugs

10

torque-indicating bolt is used, tighten using a

3/4‖ or 19-mm socket torque wrench set at

50ft-lb (68N-m). The color indicator should turn

fully black and can be viewed periodically to

insure proper torque.

NOTE: The bolt head may be relocated to the

opposite side of the busway to improve

accessibility.

NOTE: La tête du boulon peut être repositionnée

sur le côté opposé de la canalisation pour barres

omnibus pour la rendre plus accessible.

13. Tighten all 3/8" joint cap screws to 25 lb-ft (34

N-m) with a 9/16" or 14-mm socket wrench

and all 5/16" joint cap screws to 10 lb-ft (14 N-

m) with a 1/2" or 12-mm socket wrench.

14. During installation, occasionally megohm test

the assembly to check for any improperly

made joints. Resistance should not drop below

1 megohm per 100 feet of busway.

15. Megohm test the complete run before

energizing.

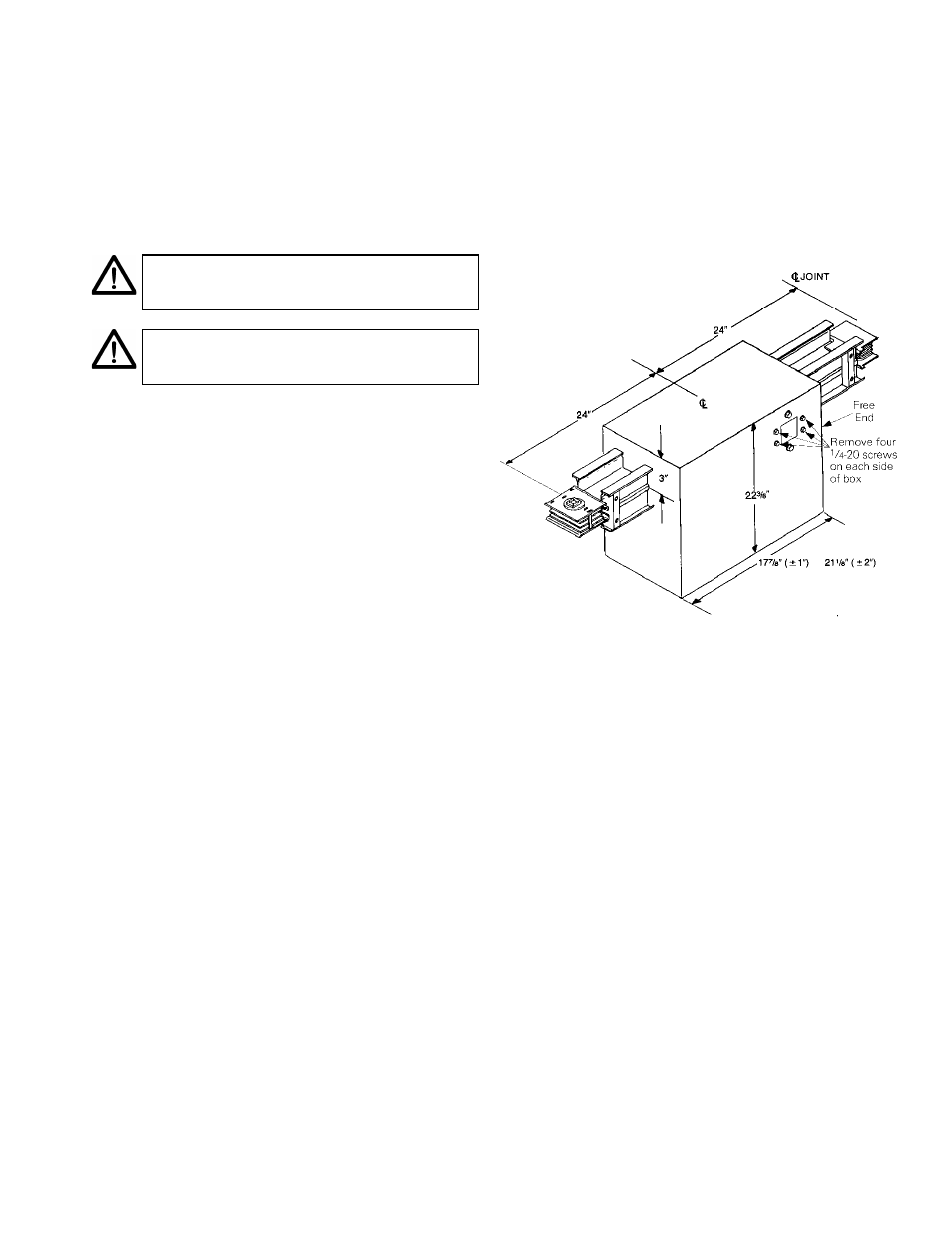

Expansion Lengths

Expansion lengths compensate for thermal

expansion of a long busway run or for differential

expansion between two buildings spanned by a

busway run. One end wall of the expansion box is

free to move, but only after the eight 1/4-20

shipping screws are removed.

Install the expansion length and the remaining

busway run, as shown in Figure 14. All but the

farthest busway supports beyond the box’s free

end must be nonrigid, such as spring hangers for

riser (vertical) busway or drop rod assemblies on a

horizontal run. Before energizing the run, remove

the eight 1/4-20 shipping screws, four on each

side of the box, as identified by two labels.

Tips for installing expansion lengths

The label and shipping screws are near the

box’s free end.

Use a 3/8" (6- or 12-point) or 10-mm (6-point)

socket wrench to remove the 1/4-20 shipping

screws.

An elbow below a riser that is supported by a

drop rod less than 8 feet from the elbow

should be considered rigidly mounted.

Figure 14. Installing an expansion length.

Busway Field Check Pieces and Replacement

Pieces

A field check piece is a length of busway inserted

into a run after the major portion of that run has

been installed. To determine the length of the

piece to be inserted, measure the opening length

L between the ends of the bars and the center of

the joint of the adjacent piece and subtract .875

inches, as shown in Figure 15. This is equal to the

busway length X measured from the center lines

of joint to joint and is the way to measure all

Spectra Series busway pieces.