GE Industrial Solutions Spectra II Series Plug-in and Feeder Busway with BlueCoat Epoxy Insulation System User Manual

Page 26

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing Spectra II Series Busway

24

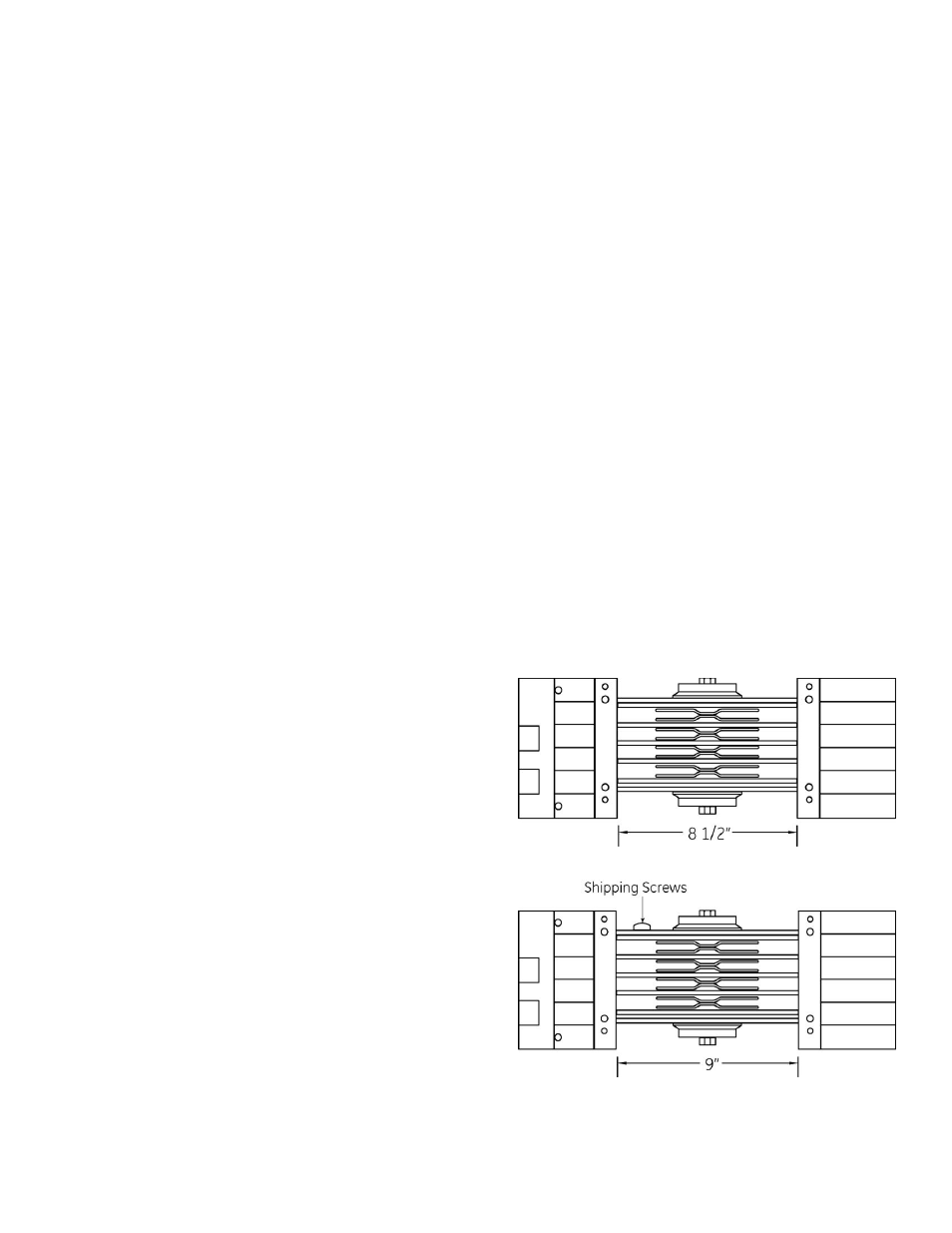

3. Align sections to be joined by matching up

―Ø side‖ labels attached at ends of each

section.

4. If necessary, loosen joint bolt slightly.

5. Slide sections together. Make sure that the

busbars interweave the insulators as shown

in Figure 36-38. NOTE: the housing ground

side plates must pass between the outside

insulators and the joint sides.

6. The standard distance between the

housings is 9‖ as shown in Figure 37.

However, the joint is also adjustable as

shown in Figures 36-38. Simply move the

sections in or out to the desired length as

shown and remove the twist outs in both

joint caps. See Figure 39 NOTE: Remove

shipping screw to center joint when

adjusting to max. and min. length.

7. Insert mounting screws into the joint cap

which is already attached and tighten to

align centerlines of the two bus sections.

8. Inspect busway run for the straightness in

all planes, and make adjustments, if

necessary, for good alignment.

9. Lubrication grease has been applied to the

joint bolt head and thread to reduce friction.

Do not remove this grease.

10. Tighten the joint bolt to 50 foot-pounds.

When the Belleville springs on both sides are

flattened, the bolt is fully torqued. The bolt

head may be relocated to the opposite side

of the busway if it is inaccessible.

11. Install second joint cap and tighten the joint

cap screws.

12. During installation occasional meggering

should reveal any improperly made

assemblies. Resistance should not drop

below one megohm for 100 feet of busway.

Megger the complete run before energizing.

To Remove the Joint or Captive Piece of

Busway

Should it become necessary to isolate for

testing or troubleshooting a piece or run off

Spectra and Spectra II Series ™ busway the

joint is designed for easy removal either during

or after installation.

1. De-energize the busway. Remove either

joint cap.

2. Remove the shipping screw, illustrated in

Figure 37.

3. Grasp the joint sides and pull toward the

narrow side of the busway. A gently rocking

motion may necessary to aid the joint in

sliding out.

NOTE: With the joint removed the busway is

segmented and section of the run away

from the source is electrically isolated from

the source.

4. To reinstall the joint, simply slide the joint

back into place. CARE MUST BE TAKEN TO

ASSURE SPLICE PLATES AND INSULATORS

ARE PROPERLY POSITIONED. It is not

necessary to reinstall the shipping screw.

5. Install joint cap(s), as required.

6. Megger at 1000VDC the complete run of

busway before energizing.

Joints With +/- .50 Inch Adjustability

Figure 36 “Minimum”

Figure 37 “Standard”