Surface mount information, Continued), Tin lead soldering – GE Industrial Solutions EVW020A0S6R0 Series (Eighth-Brick) User Manual

Page 11: Lead free soldering, Pb-free reflow profile, Msl rating, Storage and handling

Data Sheet

March 3, 2011

EVW020A0S6R0 Series Eighth-Brick Power Modules

36–75Vdc Input; 6.0Vdc Output; 20A Output Current

LINEAGE

POWER

11

Surface Mount Information

(continued)

The CP is constructed from a solid copper pin with an

integral solder ball attached, which is composed of

tin/lead (Sn/Pb) solder for non-Z codes, or Sn/Ag

3

/Cu

(SAC) solder for –Z codes. The CP connector design

is able to compensate for large amounts of co-

planarity and still ensure a reliable SMT solder joint.

Typically, the eutectic solder melts at 183

o

C (Sn/Pb

solder) or 217-218

o

C (SAC solder), wets the land,

and subsequently wicks the device connection.

Sufficient time must be allowed to fuse the plating on

the connection to ensure a reliable solder joint. There

are several types of SMT reflow technologies

currently used in the industry. These surface mount

power modules can be reliably soldered using natural

forced convection, IR (radiant infrared), or a

combination of convection/IR.

Tin Lead Soldering

The EVW020A0S6R0 power modules are lead free

modules and can be soldered either in a lead-free

solder process or in a conventional Tin/Lead (Sn/Pb)

process. It is recommended that the customer review

data sheets in order to customize the solder reflow

profile for each application board assembly. The

following instructions must be observed when

soldering these units. Failure to observe these

instructions may result in the failure of or cause

damage to the modules, and can adversely affect

long-term reliability.

In a conventional Tin/Lead (Sn/Pb) solder process

peak reflow temperatures are limited to less than

235

o

C. Typically, the eutectic solder melts at 183

o

C,

wets the land, and subsequently wicks the device

connection. Sufficient time must be allowed to fuse

the plating on the connection to ensure a reliable

solder joint. There are several types of SMT reflow

technologies currently used in the industry. These

surface mount power modules can be reliably

soldered using natural forced convection, IR (radiant

infrared), or a combination of convection/IR. For

reliable soldering the solder reflow profile should be

established by accurately measuring the modules CP

connector temperatures.

R

E

FLOW

TEM

P

(

C)

0

50

100

150

200

250

300

P reheat zo ne

max 4

o

Cs

-1

So ak zo ne

30-240s

Heat zo ne

max 4

o

Cs

-1

P eak Temp 235

o

C

Co o ling

zo ne

1-4

o

Cs

-1

T

lim

above

205

o

C

REFLOW TIME (S)

Figure 23. Reflow Profile for Tin/Lead (Sn/Pb)

process

M

AX TE

M

P

S

O

LD

ER (

C)

200

205

210

215

220

225

230

235

240

0

10

20

30

40

50

60

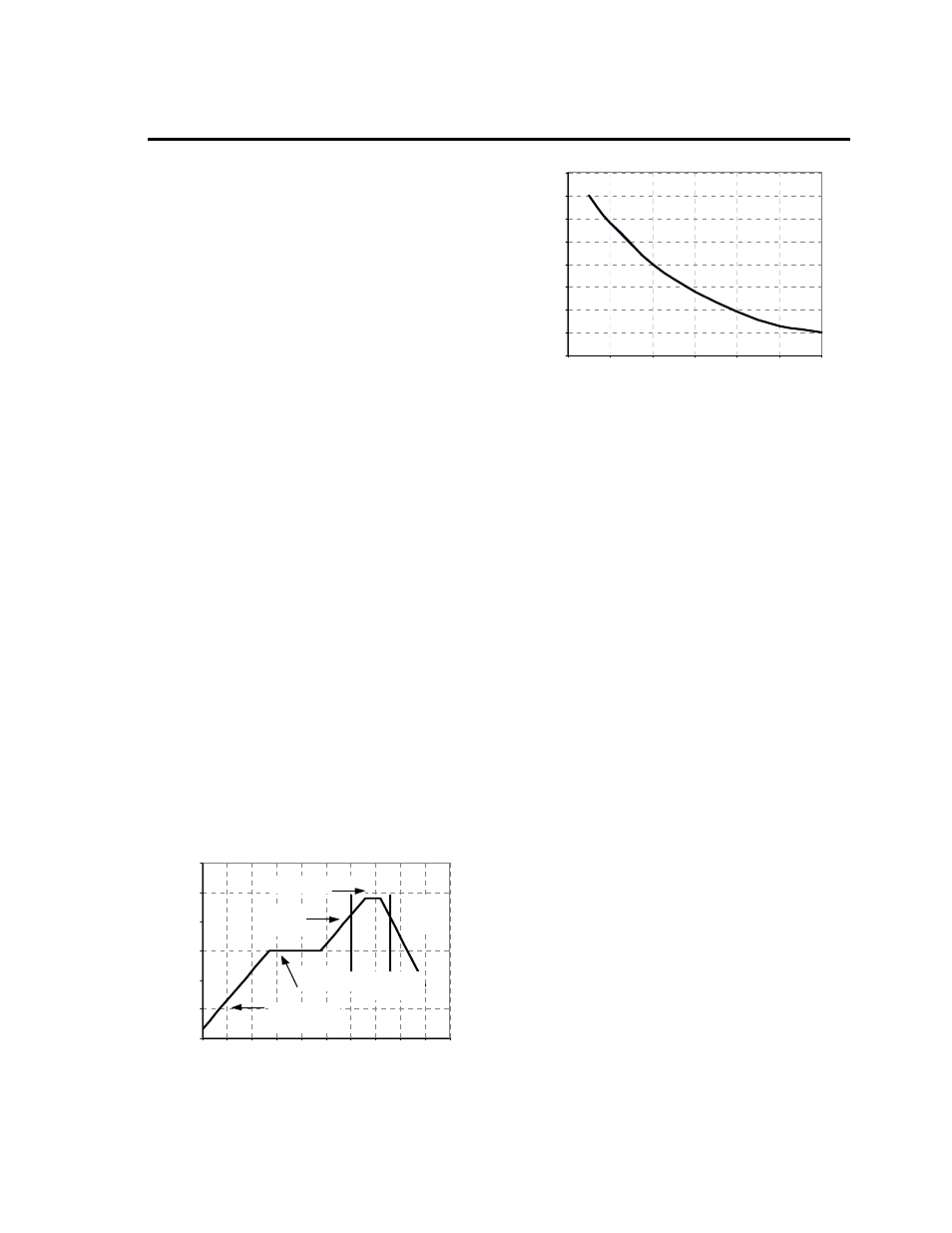

Figure 24. Time Limit Curve Above 205

o

C for

Tin/Lead (Sn/Pb) process

Lead Free Soldering

The –Z version of the EVW020A0S6R0 modules are

lead-free (Pb-free) and RoHS compliant and are both

forward and backward compatible in a Pb-free and a

SnPb soldering process. Failure to observe the

instructions below may result in the failure of or cause

damage to the modules and can adversely affect

long-term reliability.

Pb-free Reflow Profile

Power Systems will comply with J-STD-020 Rev. C

(Moisture/Reflow Sensitivity Classification for

Nonhermetic Solid State Surface Mount Devices) for

both Pb-free solder profiles and MSL classification

procedures. This standard provides a recommended

forced-air-convection reflow profile based on the

volume and thickness of the package (table 4-2). The

suggested Pb-free solder paste is Sn/Ag/Cu (SAC).

The recommended linear reflow profile using

Sn/Ag/Cu solder is shown in Figure 25.

MSL Rating

The EVW020A0S6R0 modules have a MSL rating of

2a.

Storage and Handling

The recommended storage environment and handling

procedures for moisture-sensitive surface mount

packages is detailed in J-STD-033 Rev. A (Handling,

Packing, Shipping and Use of Moisture/Reflow

Sensitive Surface Mount Devices). Moisture barrier

bags (MBB) with desiccant are required for MSL

ratings of 2 or greater. These sealed packages

should not be broken until time of use. Once the

original package is broken, the floor life of the product

at conditions of

30°C and 60% relative humidity

varies according to the MSL rating (see J-STD-033A).

The shelf life for dry packed SMT packages will be a

minimum of 12 months from the bag seal date, when

stored at the following conditions: < 40° C, < 90%

relative humidity.