Maintenance and service information – Buyers 13006039 User Manual

Page 4

4

Maintenance and Service Information

All installations, re-installation, and repair should

be done by a qualified authorized distributor of

Buyers Products. All replacement parts must be of

original quality.

Safety Decals must be attached visually. All

missing decals should be replaced before usage.

No Modification is to be made without the explicit

authorization of Buyers Products. Use ONLY SAM

low temperature hydraulic fluid. LiftDogg Lift-

gates require preventative maintenance program

to be effectively operational. Service is recom-

mended every 120 days or 1500-2000 cycles—

whichever comes first.

• Check for leaks from cylinders, hoses, and

all fittings. Replace or repair as needed to

prevent leaking.

• Grease all fittings with grease gun. A taper

nose fitting tool may be needed in conjunc-

tion with the grease gun.

• Grease all rotating pins. Pins are designed

to take the taper nose fitting tool when

pressure upon the surface, grease can be

pumped into the small opening. Regrease

every 120 days.

• Replace any excessive worn parts.

• If needed, adjust platform latches designed

to properly lock the gate in the stored posi-

tion.

• Check for all welds for cracks to see if repairs

are necessary.

• Check all electrical connections. Clean or

repair if corroded.

• Replace fuses, if needed. Check electric cable

for worn or damaged insulation.

• Replace or clean safety decals, so that they

are legible.

• Check key switch control operation.

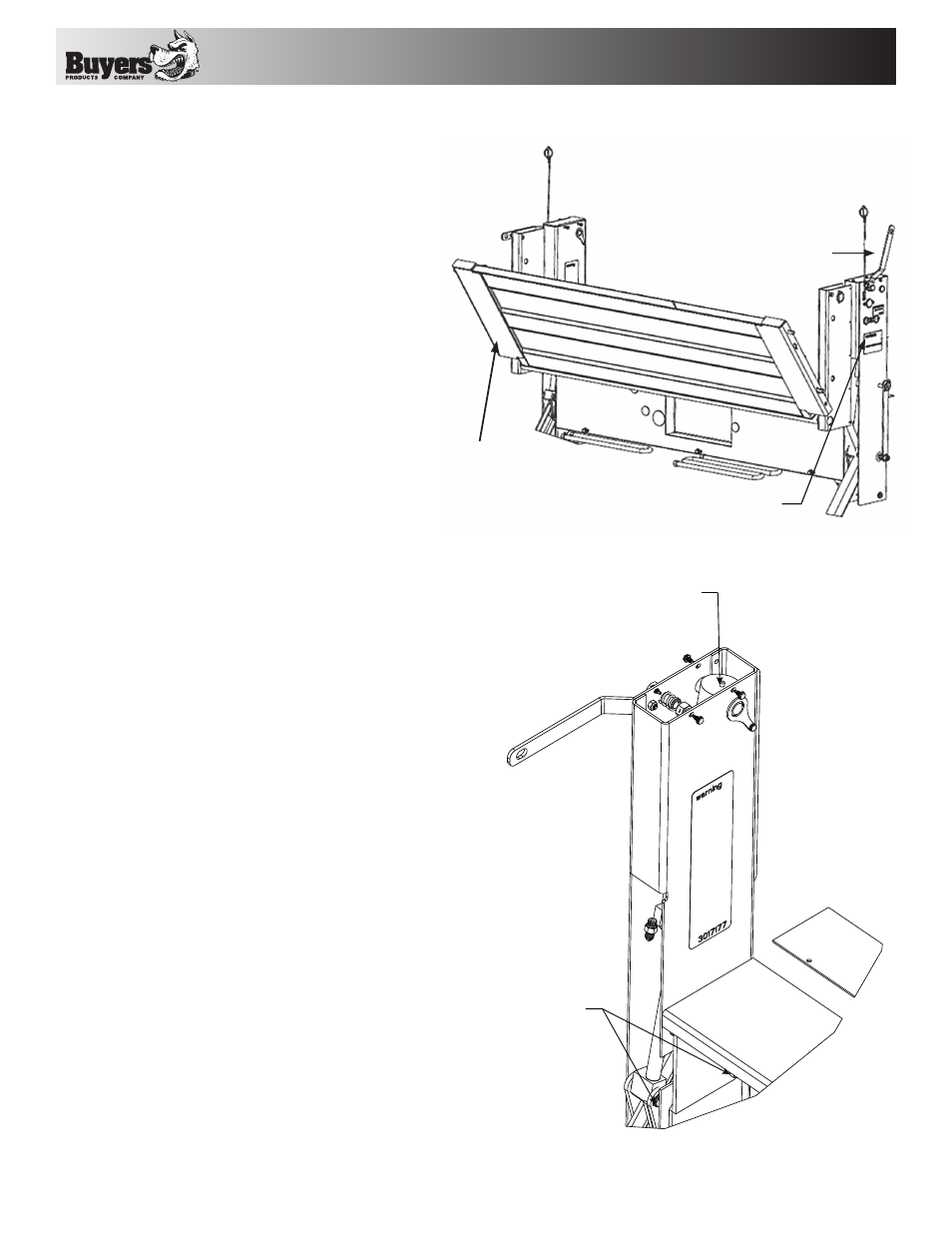

GREASE FITTING

GREASE PIN

HEADS AND BUSHING

REPEAT FOR ALL PINS

Tilt platform

downward

Turn lever clockwise to up position

on both sides to unlock gate.

Insert key and turn counter-clockwise

to move platform downward, turn key

clockwise to raise platform upward.

Fig. 6.

Fig. 7.