Buyers P45AC6 User Manual

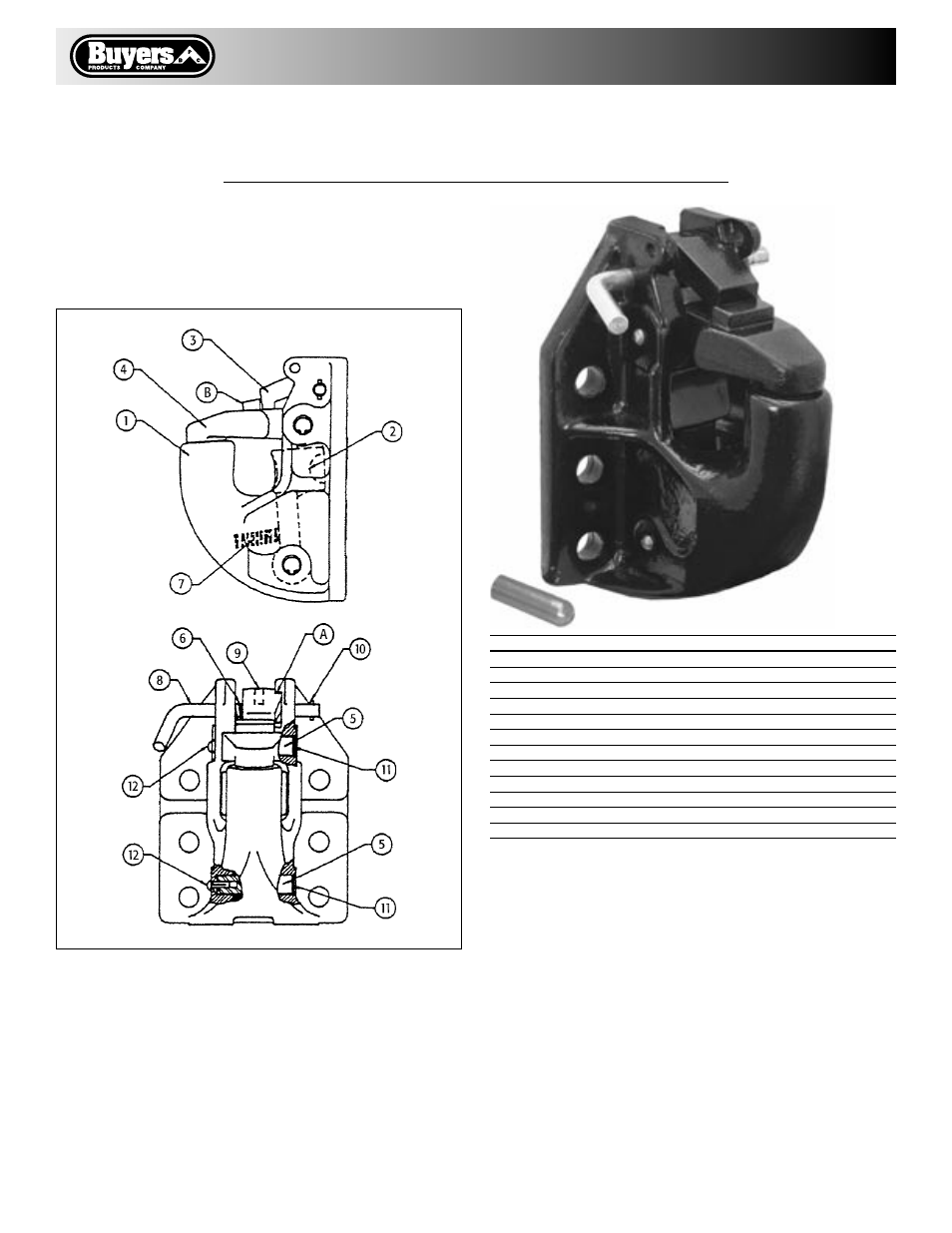

Rebuild instructions, P45ac6 air compensated pintle hook, Inspection

Quality since 1946

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax (800) 841-8003 • buyersproducts.com

B. Pivot Shaft Inspections

1. Verify that the Shafts (5), Snap Rings (11), and

Grooved Pin Rivets (12) are in place and secure.

See Fig. 1 on pg. 2 for proper location of Snap Rings.

C. Jaw Inspection

1. Place a properly matched lunette eye on the

hook, lower the Jaw (4) and apply operating pres-

sure to the air chamber.

2. With the Lock disengaged, as shown in Fig. 2 on

pg. 2, lift the Jaw (4) until it stops. The secondary

interlock feature must prevent the Jaw from open-

ing more that 1/2” above the horn.

Rebuild Instructions

P45AC6

Air Compensated Pintle Hook

–continued

Use with replacement part kits: C6200, C6300, & C6400

ITEM NO. PART NO.

DESCRIPTION

C6200

C6300

C6400

1

-

Body Casting

-

-

-

2

C4002

Plunger Arm

1

-

1

3

C6003

Lock

-

1

1

4

C6004

Jaw

1

-

1

5

C6005

Shaft

2

-

2

6

C6006

Torsion Spring

1

1

1

7

C6007

Compression Spring

1

-

1

8

C6008

Actuator

-

-

1

9

C6009

Set Screw

-

1

1

10

C6010

Roll Pin

1

1

1

11

C6011

Retaining (Snap) Ring

2

-

2

12

C6012

Grooved Pin (Rivet)

2

-

2

INSPECTION

A. Body Inspection

1. Visually inspect the pintle hook Body Casting

(1) for signs of excessive wear, or fatigue such as

deformation or cracks. If any such conditions are

noted, the entire hook should be replaced. (This is

a good time to check the mounting structure, bolts,

and air chamber. Contact vehicle manufacturer for

guidelines.)