R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Select Service Manual User Manual

Page 33

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

33/46

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

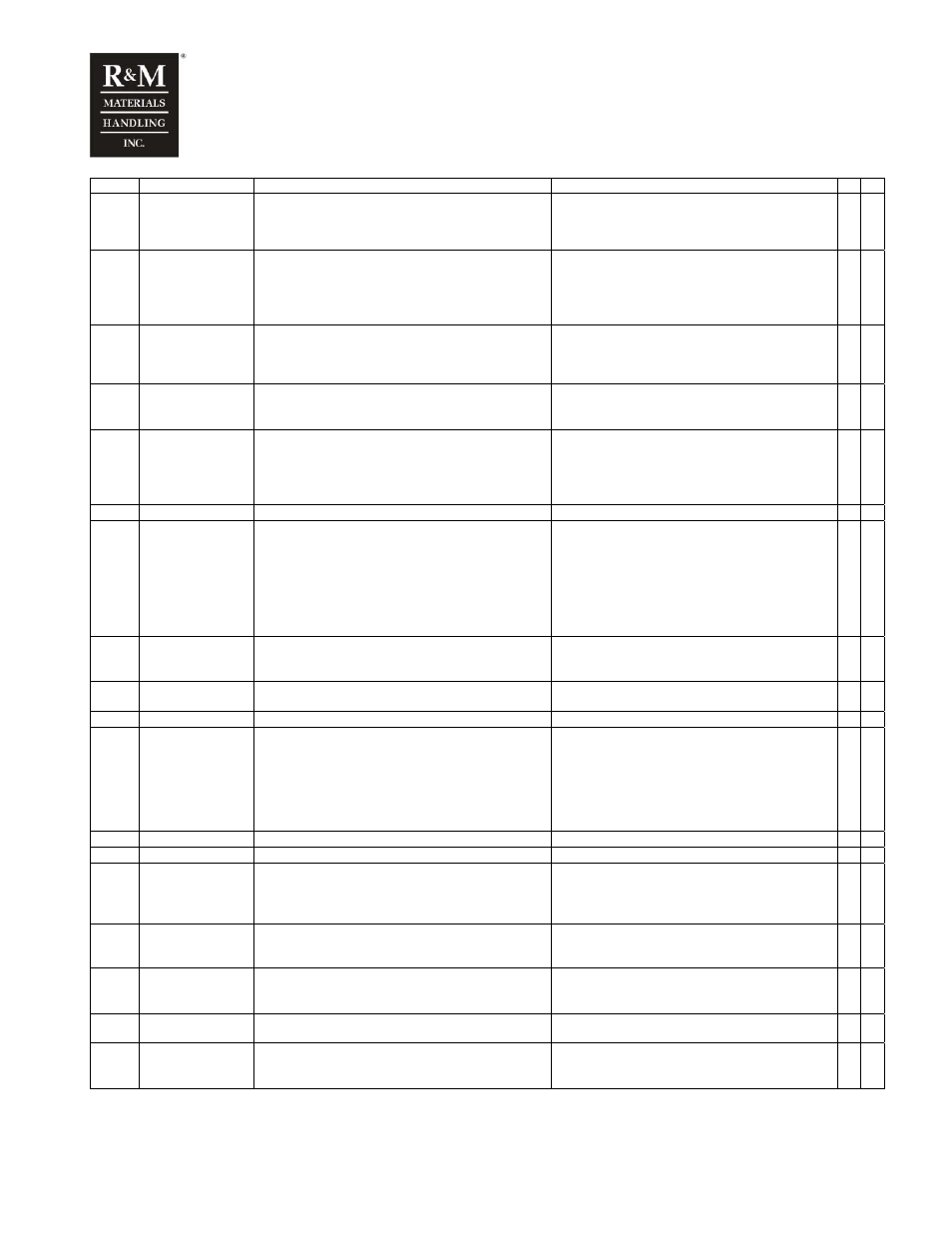

ES signal, check motor temperature.

F 8

System fault

Component failure

Faulty operation

Reset: switch power off and restart after the lamps of

display are off.

If the fault comes again, contact authorized service

center.

X

F 9

Undervoltage

DC-bus voltage has dropped below 333Vdc

mains supply voltage interrupted

inverter fault can also cause an undervoltage trip

external fault during run may cause an undervoltage

trip

In case of temporary supply voltage break, reset the

fault and start again. Check mains input.

If mains supply is correct, an internal failure has

occurred.

Contact authorized service center.

X

F 11

Output phase

supervision

Current supervision has sensed that at least one of the

motor phases has no current

Check:

motor cable connections

measure motor phase currents and compare to

display value

X

F 13

Inverter

undertemperature

Temperature of heat sink is below acceptable operating

level -10°C (14°F)

Check

ambient temperature

cubicle heating

X

F 14

Inverter

overtemperature

Temperature of heat sink is over acceptable operating

level +90°C (194°F).

Overtemperature warning is issued when the heat sink

temperature exceeds +85°C (185°F)

Check:

ambient temperature

inverter cooling fan operation

cooling air flow through heat sink

heat sink is not dirty

X

F 16

Parameter P1.4.1 has value “1” or “2”

Change Parameter P1.4.1 to value “0”

X

F 22

F 23

EEPROM

checksum fault

Parameter save error

interference fault

component failure (control unit)

After power off the inverter will automatically reset

parameter settings. The drive does not work properly

nor enable driving after this fault.

Check:

all parameter settings.

+24V voltage output loading

If the fault comes again, contact authorized service

center.

X

F 25

Microprocessor

watchdog-fault

interference fault

component failure (control unit)

Reset: switch power off and restart after the lamps of

display are off.

If the fault comes again, contact service center.

X

F 39

Device removed

Option board removed.

Reset the fault

Check option board connection

X

F 40

Device unknown

Unknown option board or drive.

Check board and drive type.

X

F 41

IGBT temperature IGBT transistors is calculated to be over heated

long duration overload

lowered cooling

high environment temperature

Reset: switch power off and restart after the lamps of

keypad are off. Check:

motor loading

brake operation

inverter heatsink

inverter cooling fan operation

environment temperature

X

F 44

Device changed

Option board changed.

Reset the fault

X

F 45

Device added

Option board added.

Reset the fault

X

F 51

Stop limit

S12 or S22 signal is inactive

Reset: keep controller at zero >300ms.

Check control mode selection P1.1.11

Check the state of inputs DID4 and DID5, V2.3

Hoisting application: check Dold settings

X

F 55

Board fault

Option board is missing or not working

Reset: switch power off and restart after the lamps of

display are off.

Check: Option board

X

F 56

Generator side

current limit

The inverter cannot stop with the set ramp stretching, it

will stop by brake and show F56

Too short deceleration time

Reset has an additional 5 s time delay.

Check:

deceleration time

X

F 60

Parameter fault

“Motor selection” parameter P1.2.2 has value = “Not

Used”

Download parameters again

X

F 73

Both drive

commands active

S1 and S2 signals on over 500ms in same time

The inverter stops according “Stop Function” parameter

Short circuit in pendent cable

Check:

digital I/O cabling

X

A = Can be done by the user

B = Can be done only by manufacturer authorized personnel