1 voltage at low frequencies (u/f- curve), 1 starting values, Ui r – R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Select Service Manual User Manual

Page 19: 2 midpoint voltage adjustment, 3 zero frequency voltage adjustment, 4 test run, And i

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

19/46

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

5.4.1 Voltage at low frequencies (U/f- curve)

Following parameters need to be set for U/f setting. For listed motors, values of these parameters are

stored into the inverter memory, but they can also be set manually or by Autotuning. The manual setting

procedure is as follows:

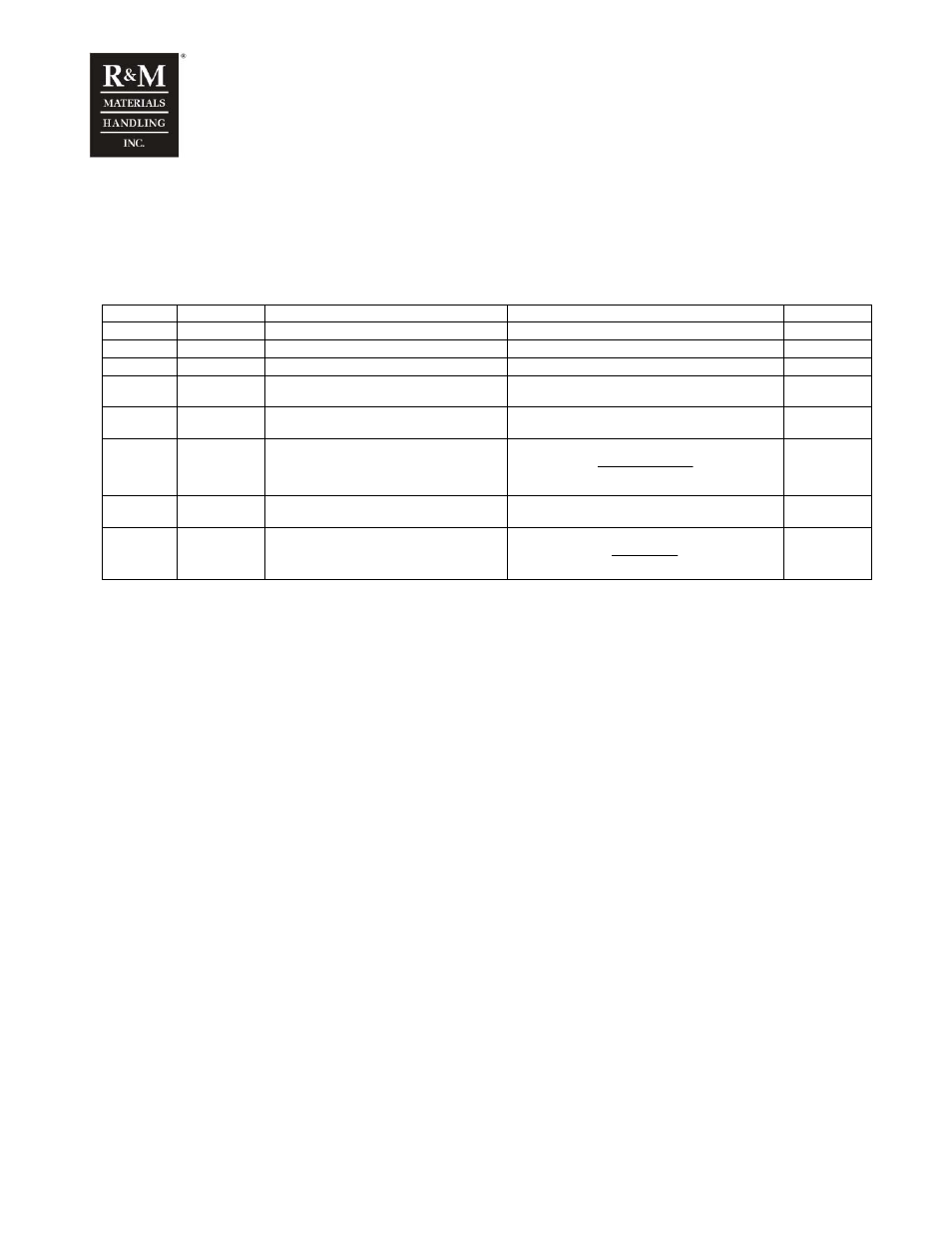

5.4.1.1 Starting values

Value

U

N

P1.2.1

Motor nominal voltage

From motor nameplate

V

f

N

P1.2.4.1

Motor nominal frequency

From motor nameplate

Hz

I

N

P1.2.4.2

Motor nominal current

From motor nameplate

A

R

S

Not

parameter

Stator resistance of motors + cable

resistance

Resistance between phases. Measured on

disconnected motor cable ends at terminal X1.

Ohm

I

0

P1.2.4.3

Flux current

From motor nameplate

(if not available, set to value 0,5*I

N

)

A

U

f0

P1.2.5.1

Zero frequency voltage % of nominal

voltage (voltage at 0Hz)

N

S

U

I

R

0

*

*

100

%

U

mid

P1.2.5.2

Midpoint voltage % of nominal voltage

(voltage at f

mid

)

0

*

41

,

1

f

U

%

f

mid

P1.2.5.3

Midpoint

frequency

100

*

0

N

f

f

U

Hz

#

If several motors are connected in parallel, the correct value of R

S

is the resistance of one motor

divided by the number of motors. The correct value of I

N

and I

0

are the value of one motor multiplied

by the number of motors

5.4.1.2 Midpoint voltage adjustment

-

Check that there is no load on the crane.

-

Set minimum speed for both directions (P1.1.4) to value f

mid

.

-

Drive at maximum speed and check the motor current from parameter V2.5.

-

Drive at minimum speed. Motor current should be approximately average of measured maximum speed current

and the I

N

.

-

Adjust value of parameter U

mid

(P1.2.5.2) until current at minimum speed (= f

mid

) is within desired range.

5.4.1.3 Zero frequency voltage adjustment

-

Set minimum speed for both directions (P1.1.4) to value 0.5 * f

mid

.

-

Drive at minimum speed. Motor current should be approximately average of measured maximum speed current

and the I

N

.

-

Adjust value of parameter U

f0

(P1.2.5.1) till current at minimum speed (=0.5 * f

mid

)

is within desired range

5.4.1.4 Test run

-

Set minimum speed for both directions (P1.1.4) to desired minimum speed.

-

Drive at minimum speed with nominal load to both directions.

-

If motor is not driving at minimum speed, increase values of parameters U

f0

and U

mid

, then continue from

Midpoint voltage adjustment.

#

If the main girder is new, it might be necessary to drive trolley several times with no load from end

to end, before beginning of u/f-curve tuning.