R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Select Service Manual User Manual

Page 23

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

23/46

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

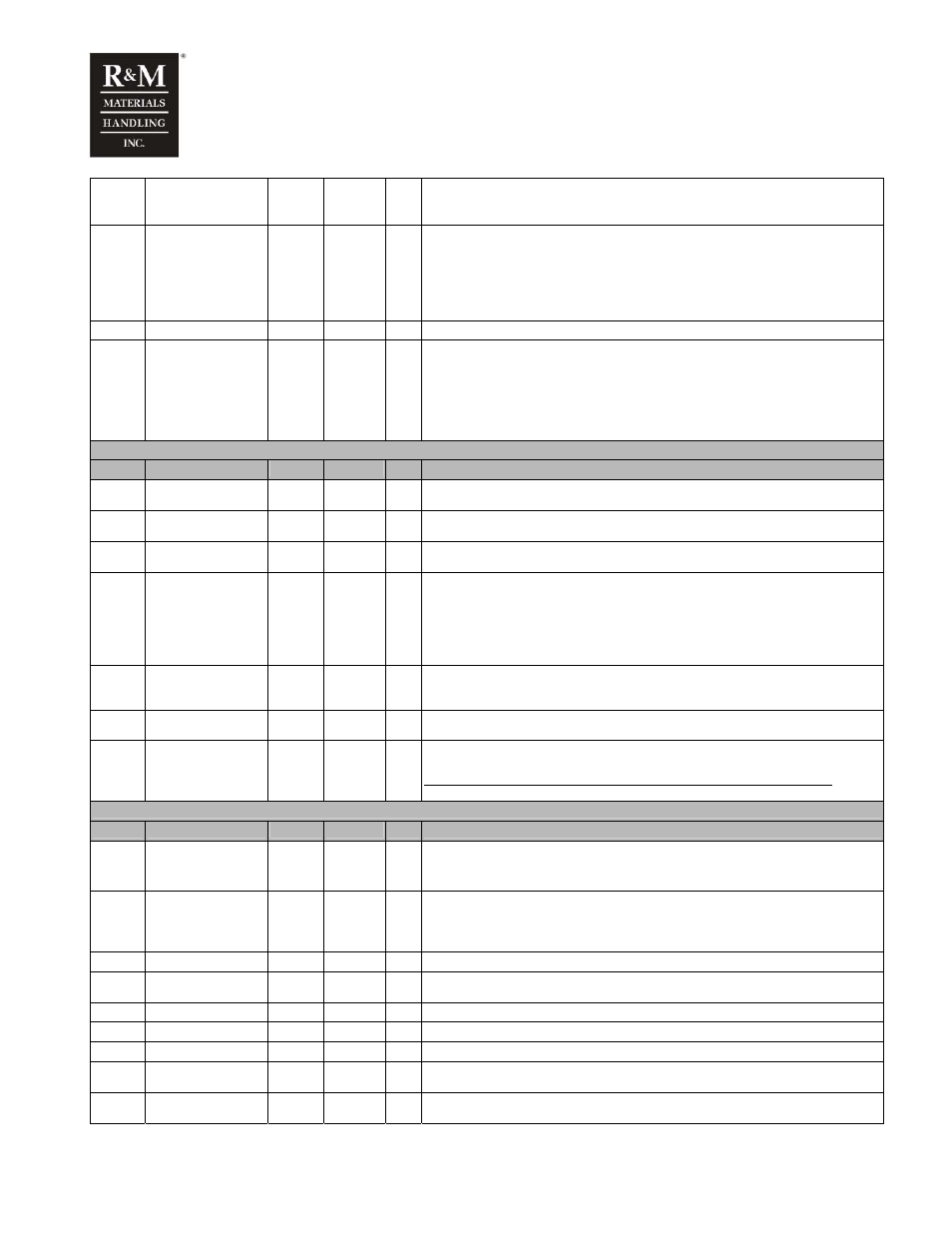

P1.2.4.3 Motor Nominal Flux

Current

0.0

A

Motor nominal flux current (Io), same as no-load current or magnetizing current from

motor nameplate. In multimotor drives nominal flux currents must be summed up.

P1.2.4.4 Current Limit

0.0

A

Defines the maximum motor current from the inverter. If the output current exceeds the

value set in parameter P1.2.4.4 the output frequency is lowered until the current drops

below the current limit.

Typical value is 1.5 times motor(s) nominal (1,5xIn). In multimotor drives nominal

currents must be summed up.

Must not be set over inverters max 1min. current.

P1.2.4.5 Motor Cos Phi

0.00

1.00

From motor nameplate (Power factor)

P1.2.4.6 Autotuning 0

4

See

Chapter "Autotuning"

0 = Not Done

1 = Tuning

2 = Failed

3 = Done

4 = Modified

G1.2.5 U/f Settings, see note1

Code

Name

Min

Max

Unit Description

P1.2.5.1 Zero Frequency

Voltage

0.00

40.00

%

Output voltage at zero frequency, % of motor nominal voltage.

P1.2.5.2 U/f Middle point

Voltage

0.00

100.00

%

Voltage in the selected middle point frequency, % of motor nominal voltage.

P1.2.5.3 U/f Middle point

Frequency

0.00

120.00

Hz

Middle point frequency.

P1.2.5.4 Torque Boost

0

1

Torque maximization

0 = Off

1 = On

Torque boost is adjustable with parameters P1.2.5.5 “IrAdd Motor” and P1.2.5.6 “IrAdd

Generator” when “Free Travel” or “Free Hoist” is selected with parameter P1.2.2 “Motor

Selection”

P1.2.5.5 IrAdd Motor

0

100

With small speeds and heavy load the drive may not have enough voltage to produce

sufficient torque. Raising the value of parameter increases the voltage. Default value is

30% in travelling and 100% in hoisting.

P1.2.5.6 IrAdd Generator

0

100

If motor voltage at generator area is too high, reducing value of parameter decreases

the voltage. Default value is 50% in travelling and 0% in hoisting.

P1.2.5.7 Rs Voltage Drop

0

512

Relative value of motor stator impedance voltage drop. Value of this parameter is

calculated by formula given below.

Motor Nom Flux current x Measured motor resistance (phase to phase) x 2217 Motor

nominal voltage

G1.2.6 Brake Control, see note2

Code

Name

Min

Max

Unit Description

P1.2.6.1 Start DC-Factor

0

200

%

To adjust DC-current during starting. See P1.2.4.2

Travelling with disc brake motors 80%.

Hoisting 100%.

P1.2.6.2 Brake Opening Delay 0.00

10.00

s

Defines the opening delay of mechanical brake. “Start Freq S1” or “Start Freq S2” is

commanded during “Brk Opening Del”. After delay, output frequency increases

according to the acceleration parameters.

Default 0.05s

P1.2.6.3 Start DC-Time

0.00

5.00

s

Defines duration of the “Start Current”

P1.2.6.4 Stop DC-Time

0.00

5.00

s

Defines the function and the duration of the DC-braking time when stopping the motor. If

“Stop DC-Time” = 0 the DC-braking is not used.

P1.2.6.5 Stop DC-Frequency

0.00

250.00

Hz

Defines the DC-braking starting frequency

P1.2.6.6 Start Frequency S1

0.0

100.0

%

Defines the output frequency during brake opening delay in the S1 direction.

P1.2.6.7 Start Frequency S2

0.0

100.0

%

Defines the output frequency during brake opening delay in the S2 direction.

P1.2.6.8 Brake Stop Frequency 0.00

Max Freq Hz

Defines the output frequency when the relay output ROD1 for brake control opens

during stopping

P1.2.6.9 Minimum Frequency

Bias S2

0.00

Min Freq Hz

Helps to define the Minimum frequency in down direction for hoisting. Minimum

frequency in down direction is “Min Frequency” - “Minimum Frequency Bias S2”.