R&M Materials Handling VARIABLE SPEED CONTROLS ControlMaster Select Service Manual User Manual

Page 25

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

25/46

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

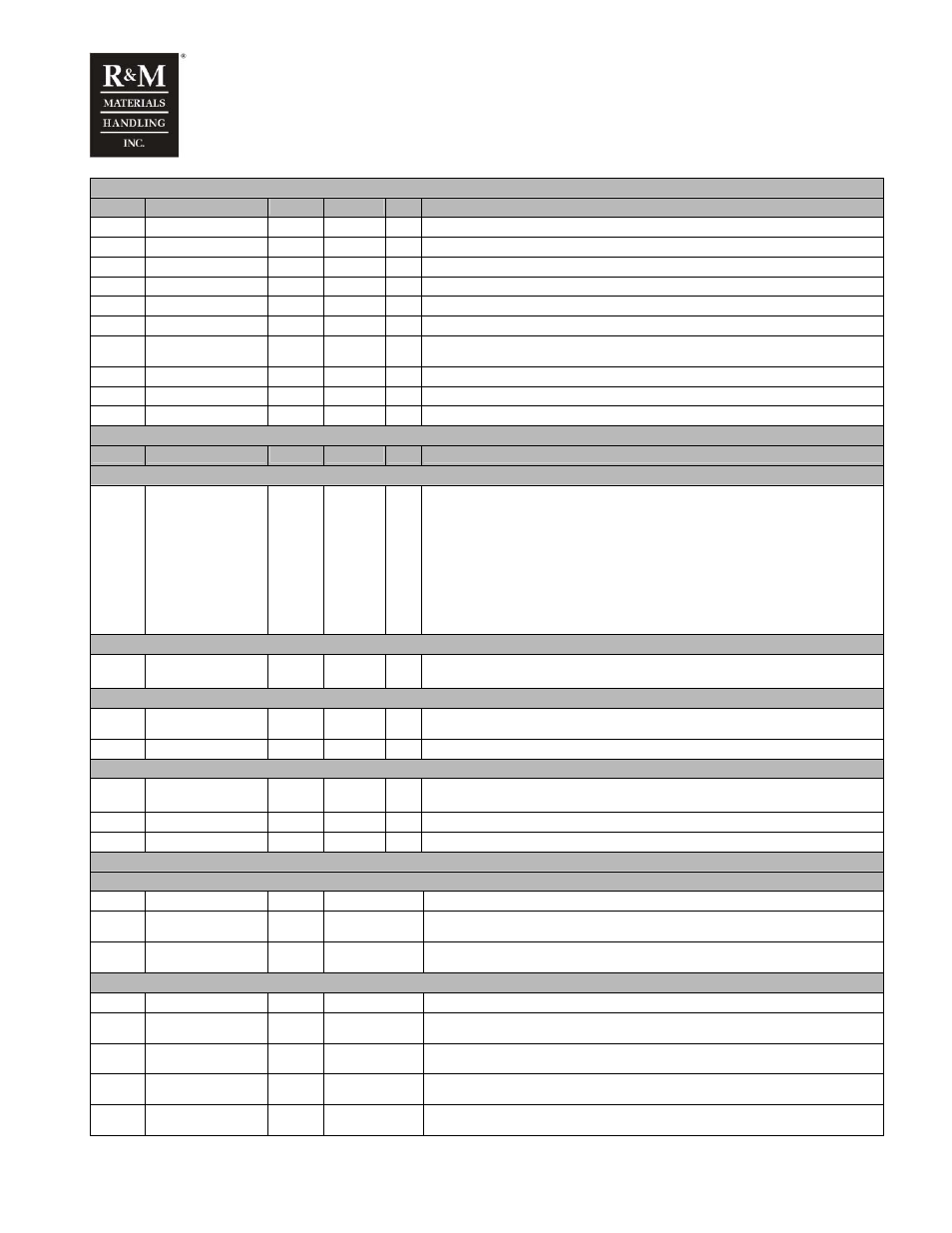

M2 Monitoring

Code

Name

Min

Max

Unit Description

V2.1

K7

0

1

State of relay output ROD1, which controls brake contactor

V2.2

ROA1

0

1

State of relay output ROA1

V2.3

DID states

.00000

.11111

State of digital input DID1-DID5, see note

V2.4

Ain1 Input

0.00

10.00

V

Value of analog input Ain1

V2.5

Motor Current

A

Measured motor current

V2.6

Motor Voltage

V

Calculated motor voltage

V2.7 Heat

Sink

Temperature

°C

Temperature of heat sink.

V2.8

DC-link Voltage

V

Actual value of measured DC-link voltage.

V2.9 Frequency

Reference

Hz

V2.10

Output Frequency

Hz

Output frequency to the motor

M3 System Menu

Code

Name

Min

Max

Unit Description

S3.3 Copy parameters

P3.3.1

Parameter sets

0 = Select

1 = Store user parameters

2 = Load user parameters

3 = Store factory parameters

4 = Load factory parameters

5 = Reset parameters

6 = Fault

7 = Wait

8 = OK

S3.5 Security (not used)

P3.5.2 Parameter

lock

0 = Change Enabled

1 = Change Disabled

S3.6 Keypad settings

P3.6.1

Default page

Display goes to Default page after Timeout time. If value 0 is selected, this feature is not

active. Default value 2.10 “Output Frequency”

P3.6.3

Timeout time

0

65535

s

Display goes to Default page after Timeout time.

S3.7 Hardware settings

P3.7.2

Fan control

0 = Continuous, default

1 = Temperature

P3.7.3

Not

used

P3.7.4

Not

used

S3.8 System info

S3.8.1 Counters menu

C3.8.1.1 MWh

counter

KWh

C3.8.1.2 Operating

days

Counter

hh:mm:ss

C3.8.1.3 Operating

hours

Counter

hh:mm:ss

S3.8.2 Trip counters

T3.8.2.1 MWh trip counter

KWh

P3.8.2.2 Clear MWh trip

counter

T3.8.2. 3 Operating days trip

counter

T3.8.2.4 Operating

hours

trip

Counter

hh:mm:ss

P3.8.2.5 Clear operating time

Counter