Duro-Last Solvent-Based Adhesive User Manual

Duro-last® sb iv adhesive, Data sheet, Duro-last: the proven performer

Duro-Last: The Proven Performer®

"Duro-Last" and "The World's Best Roof" are registered marks owned by Duro-Last , Inc.

www.duro-last.com

800-248-0280

DATA SHEET

2009

43

DURO-LAST® SB IV ADHESIVE

Description:

Duro-Last® SB IV Adhesive is a low VOC

solvent-based adhesive used to bond Duro-Last roofing

membrane to a variety of substrates on both horizontal

and vertical surfaces. Acceptable substrates include

plywood, oriented strand board (OSB), structural

concrete, DensDeck® Prime, SECUROCK®

Gypsum-Fiber Roof Board and ACFoam®-IV

polyisocyanurate insulation. Contact the Duro-Last

Engineering Services Department with questions

regarding substrates.

SB IV Adhesive has a VOC content less than 250 g/L

and meets all VOC restrictions and regulations in the

United States.

Material Safety Data Sheet (MSDS):

Product Name: Duro-Last SB IV Adhesive.

Trade Name: Low VOC PVC Bonding Adhesive.

MSDS Number / Product Code: LA432M.

Precautions:

1. Review MSDS for safety information prior to use.

2. Extremely flammable. Do not expose to heat, flame

or sparks. Do not smoke while applying.

3. Use only in well ventilated areas and avoid breathing

vapors.

4. Keep container closed when not in use.

5. When transferring adhesive between containers,

ensure that both containers are grounded.

6. Treat empty containers with caution since they may

contain flammable vapors.

7. Store in the original, unopened, container at

temperatures between 60 °F (16 °C) and 80 °F

(27 °C) and out of direct sunlight.

Installation:

1. Apply to surfaces which are clean, smooth, dry and

free of oil and grease.

2. Only apply adhesive when the ambient temperature

is at least 40 ºF (5 °C) and rising.

3. Stir adhesive vigorously by hand to achieve

homogeneous mixture prior to application. Do not

use electrical equipment or open flame near

adhesive.

4. Thinning the adhesive is not allowed.

5. Using a 3/8 inch (medium) nap solvent resistant

roller apply evenly at a coverage rate of 120 square

feet per gallon per surface to both the backside of

the membrane and to the substrate. This gives a net

coverage rate of 60 square feet per gallon (i.e.

approximately 1.7 gallons per 100 square feet). The

coverage rate will vary depending upon the porosity

of the substrate.

6. Do not apply adhesive to the membrane where

hot-air welding will be performed.

7. Allow adhesive to dry (approximately 5-10 minutes)

until it does not stick or form strings when a dry

finger is pushed into it and removed. The dry time

will vary due to ambient air conditions.

8. Open time prior to mating the membrane to the

surface may extend up to 60 minutes depending on

the ambient air conditions. However, the installer is

urged to apply the membrane to the substrate as

soon as the adhesive is ready.

9. Mate the adhesive coated membrane to the

adhesive coated substrate slowly and evenly to

avoid trapping air and to minimize wrinkles.

10.Immediately broom or roll the membrane into the

adhesive to ensure proper bonding.

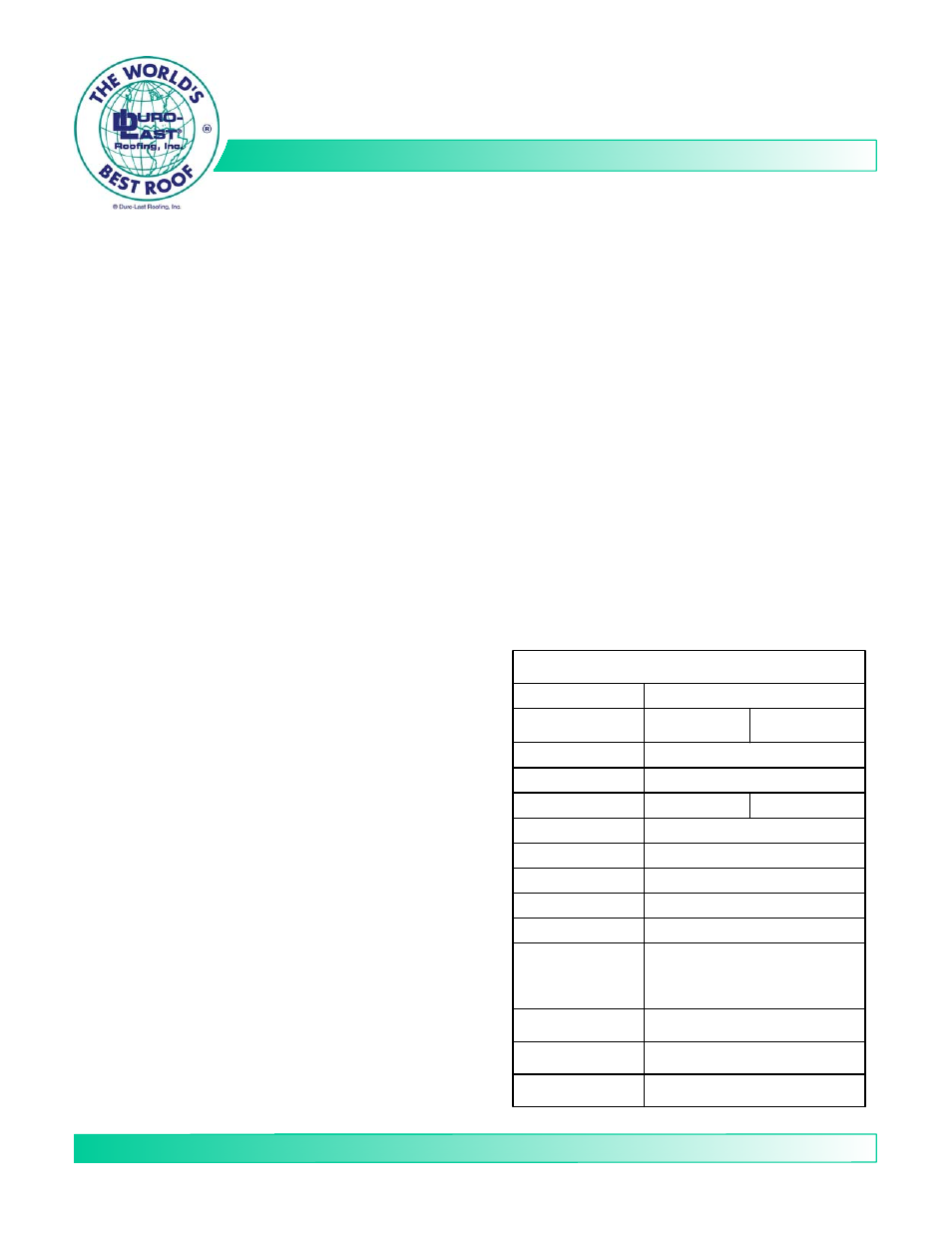

DURO-LAST SB IV ADHESIVE PHYSICAL PROPERTIES

Packaging

5 gallon pail.

Weight

7 lb. per gallon

35 lb. per pail

Base

Synthetic Polymer

Solvent

Ketone blend.

Flash Point

< 0 º F

< -18 ºC

Color

Amber

Odor

Strong solvent smell.

VOC Content

199.4 g / L

Viscosity

1,800 - 2,400 cps

Total Solids

24% ± 1%

Coverage

120 ft² per gallon per surface

for a net coverage of 60 ft² per gallon.

(i.e. 1.7 gallons per 100 ft²)

Dry Time

5 - 10 minutes.

Open Time

Up to 60 minutes.

Shelf Life

1 year, unopened.