Duro-Last Curb Flashing User Manual

Duro-last, Curb flashings, Data sheet

Duro-Last: The Proven Performer®

"Duro-Last" and "The World's Best Roof" are registered marks owned by Duro-Last , Inc.

www.duro-last.com

800-248-0280

DATA SHEET

2009

9

DURO-LAST

®

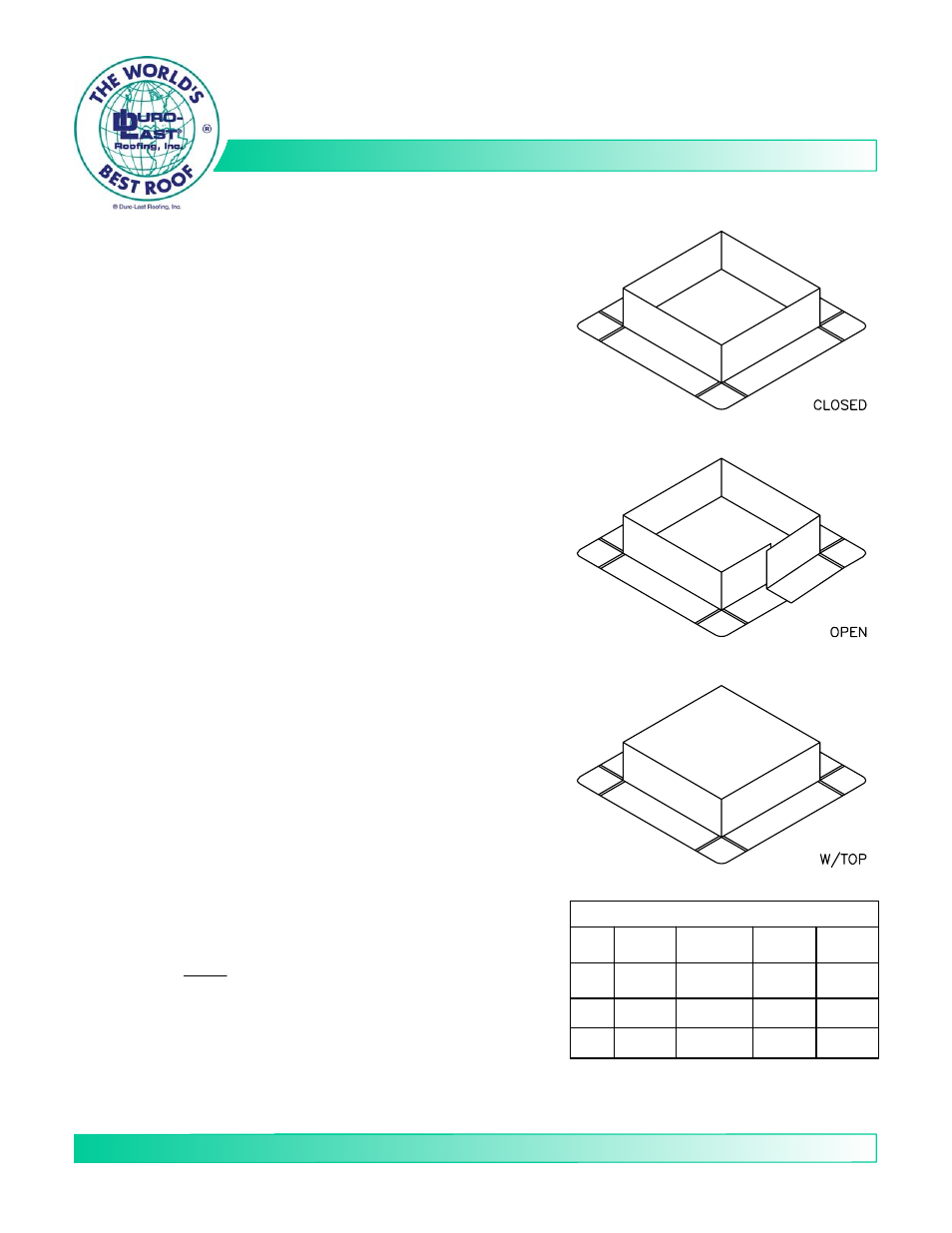

CURB FLASHINGS

Description:

Duro-Last® Curb Flashings are designed to be used on rectangular

penetrations encountered on a roofing project. The curb flashings are

made with Duro-Last specially formulated roofing membrane. The

combination of reinforced membrane and prefabrication ensures a

long lasting, watertight flashing. They are available in white, tan, gray

and dark gray colors as well as in the Designer Series membranes

(slate gray Shingle-Ply, sandstone Shingle-Ply and Rock Ply).

Curb flashings are easily heat welded (hot-air) to the Duro-Last

membrane over which the flashings are installed. Hot-air seaming

eliminates the need for chemicals, torches and other unsafe,

non-manageable seaming systems. Duro-Last Curb Flashings are

prefabricated using Duro-Last's outside corners to eliminate field

welds in the critical corner areas. Curb flashings are ordered to the

dimensions of individual penetrations. The table below show the

minimum sizes available.

Installation:

1. The roof membrane installed around the penetration must be

fastened prior to installing the curb flashing. Use the same

fastener spacing that was used to install the roof membrane but

do not exceed 18 in. (457 mm) on center. At least one fastener

must be installed on each side of the penetration. On reroofing

applications, remove the existing flashings to ensure a watertight

fit.

2. It is not necessary to place fasteners at the corners.

3. The flashing must extend a minimum of 8 in. (203 mm) in vertical

height (Note: a curb flashing with top does not have a minimum

height requirement.)

4. The curb flashing may be terminated with termination bar or

extended onto the inside of the curb. (See details 4010 & 4020).

(Note: A curb flashing with top does not require termination.)

Note:

•

An "open" curb flashing requires a heat weld (hot-air) to close the

flashing. The extra material necessary for this weld is included as

part of the flashing.

•

A curb flashing for a canted curb should be ordered using the

dimensions above the cant. A curb flashing with a 12 in. (305

mm) wide skirt will provide additional membrane to cover the cant.

•

A curb flashing with a top can be no greater than 60 in. (1525 mm)

in width and can only be ordered closed.

•

Add 1/4 in. (6.3 mm) to width and length dimensions for a better

fitting curb flashing.

•

Call Duro-Last for assistance in ordering curb flashings that need

to be designed for special situations.

MINIMUM CURB SIZES AVAILABLE

Width (A)

Length (B)

Height (C)

Skirt

Open

2 in.

(51 mm)

2 in.

(51 mm)

8 in.

(203 mm)

6 in.

(152 mm)

Closed

2 in.

(51 mm)

2.5 in.

(63.6 mm)

8 in.

(203 mm)

6 in.

(152 mm)

w/Top

3.5 in.

(89 mm)

3.5 in.

(89 mm)

3 in.

(76 mm)

6 in.

(152 mm)