Duro-Last Gravel Stop - Metal Cover User Manual

Duro-last, Gravel stop with metal cover, Data sheet

Duro-Last: The Proven Performer®

"Duro-Last" and The "World's Best Roof" are registered marks owned by Duro-Last , Inc.

DATA SHEET

www.duro-last.com

800-248-0280

35

DURO-LAST

®

GRAVEL STOP

with Metal COVER

Description:

Duro-Last

®

Gravel Stop with Metal Cover may be used

as a perimeter flashing for the Duro-Last roofing system.

The system consists of Duro-Last Gravel Stop and a

snap-on metal cover. The system has been approved by

FM Approvals as a Class 1-930 perimeter flashing.

Duro-Last Gravel Stop is fabricated from rigid exterior

vinyl and includes a 6 inch (152 mm) wide skirt made

of Duro-Last specially formulated roofing membrane

which is a proprietary thermoplastic formulation. Both

the rigid vinyl and the skirt are available in white, gray,

and tan colors. Combinations of the colors (tan face

with white skirt, for example) are available upon

request.

Duro-Last Gravel Stop is 10 feet long and available in

two widths: 2 inches (51 mm) and 4 inches (102 mm).

The Gravel Stop has pre-punched slotted holes

8 inches (203 mm) on center for fastening.

The metal cover is 10 feet long and available in

24-gauge galvalume steel with 35 stocked finishes as

well as in these specialized metals:

*

.040 aluminum with Kynar finish.

*

.040 aluminum with mill finish.

*

16-oz. copper.

*

24-gauge stainless steel.

*

24-gauge bonderized (paintable) steel.

Contact Duro-Last, Inc. to request a color chart,

samples and information regarding custom metals and

finishes.

Installation:

1.

Gravel Stop can be installed on any flat edge

including the top of parapet walls. The edge must be

straight and even (refer to details 3090 and 3100).

2.

Attach the roofing membrane over the edge to hold it

in place.

3.

It is recommended not to use prefabricated vinyl

gravel stop corners when using a metal cover.

4.

Fasten the Gravel Stop to the deck or wood nailer

with approved fasteners spaced 8 inches (203 mm)

on center.

5.

It is necessary to allow 1 inch (25 mm) spacing

between each section of Gravel Stop.

6.

Heat weld (hot-air) the Gravel Stop skirt to the field

membrane.

7.

The metal cover should be installed so that the joints

between sections are offset a minimum of 12 inches

(25 mm) from the joints between sections of the

Gravel Stop.

8.

Adjacent sections of cover are designed to overlap.

No joint clips are required.

9.

Refer to detail drawings 3520 and 3530 for

installation information.

Note:

Gravel Stop and metal cover are ordered separately in

10 foot lengths. They will be packaged in cardboard

tubes or wooden crates.

The cover is shipped with a protective plastic film

which should be removed prior to installation.

To clean the metal cover use soap and water (i.e.

1/3 cup laundry detergent per gallon of water).

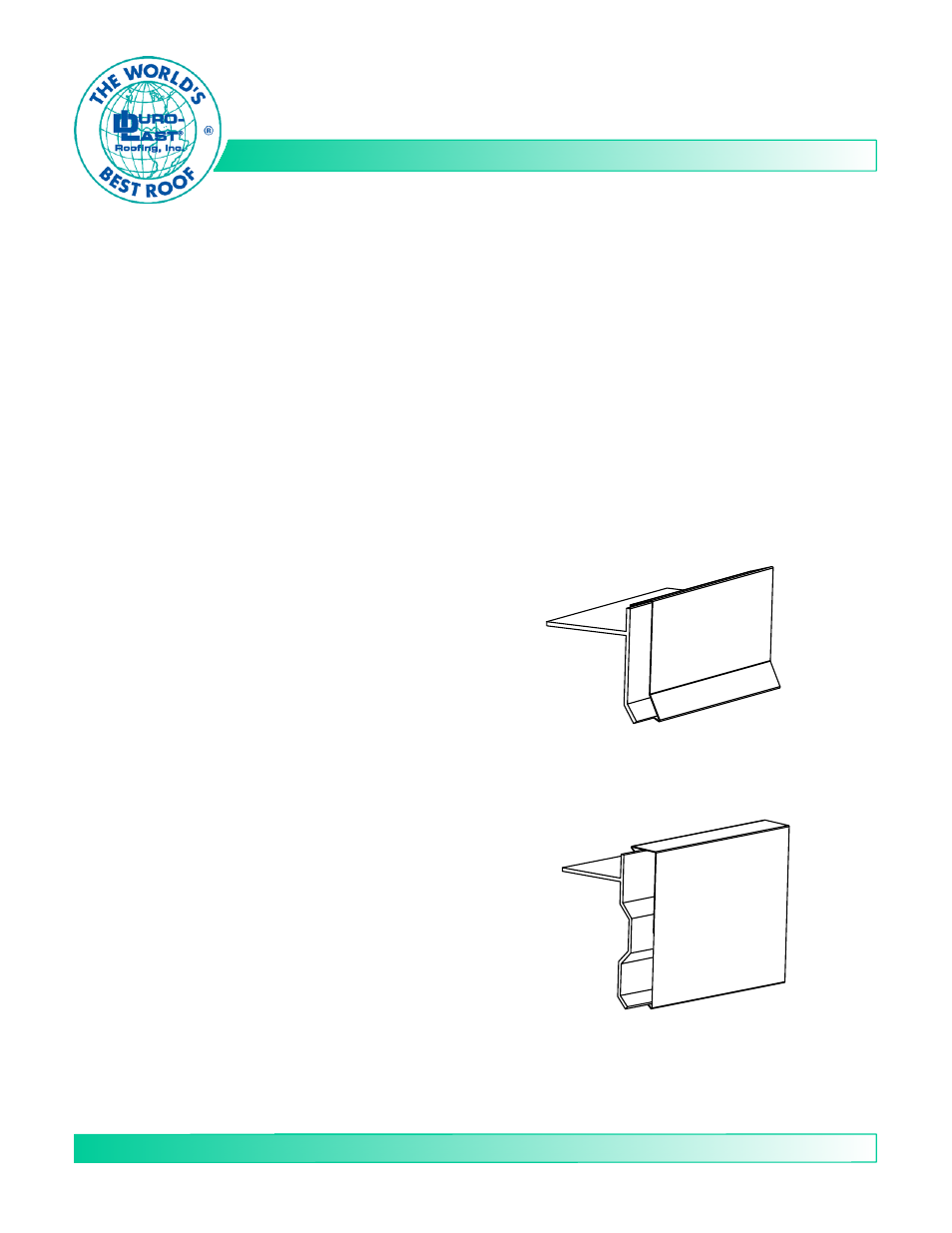

2" (51 mm) wide

Gravel Stop with Metal Cover

(see detail 3520)

4" (102 mm) wide

Gravel Stop with Metal Cover

(see detail 3530)

Revised: 12/15/2011