Duro-Last ISO HD User Manual

Duro-guard, Iso hd

Duro-Last, “World’s Best Roof” and Duro-Guard are registered marks owned by Duro-Last, Inc.

Updated: 10/31/2013

DURO-GUARD

®

ISO HD

1 of 2

www.duro-last.com 800-248-0280

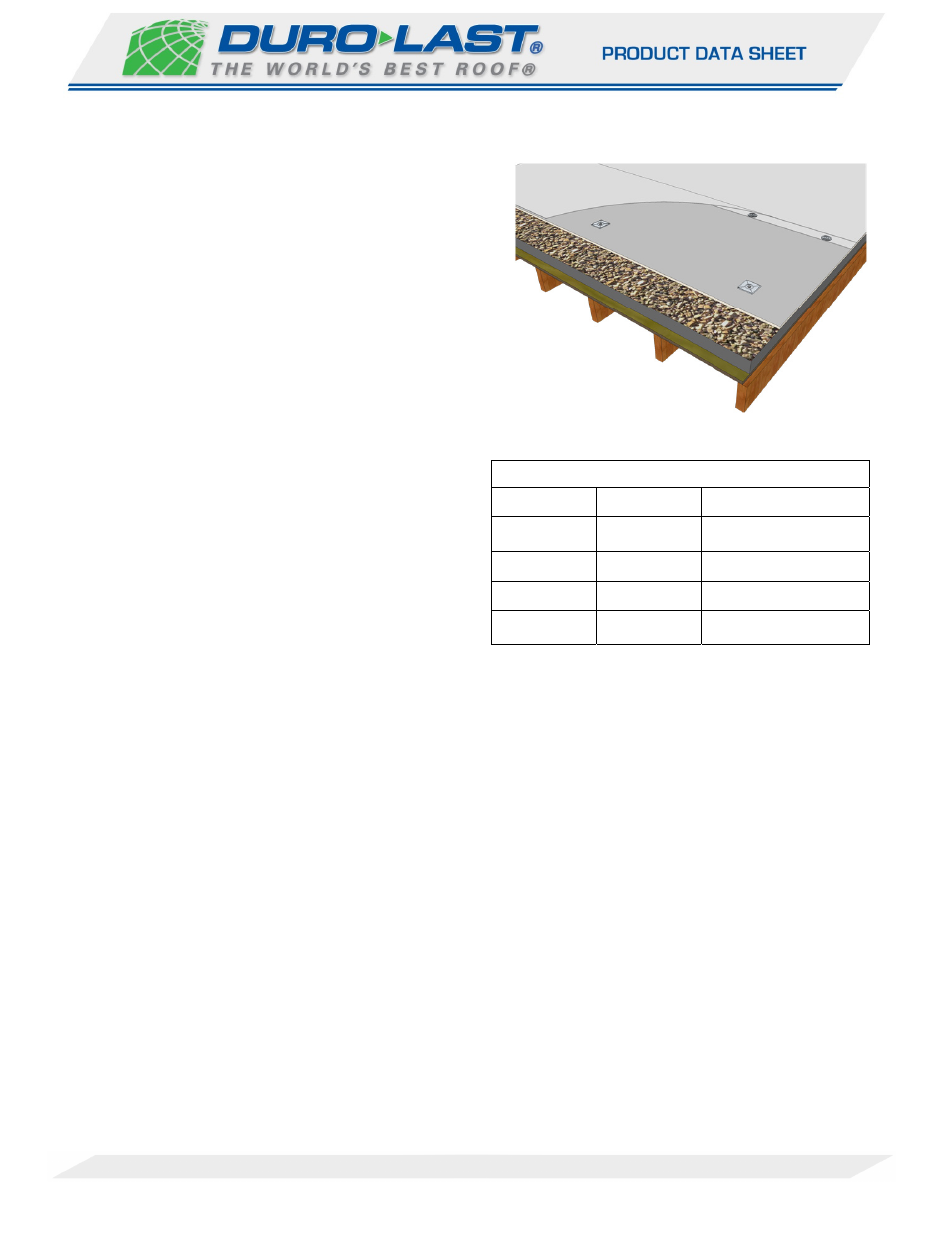

Figure 1. Duro-Guard ISO HD (Shown as Recover Board)

Description:

Duro-Guard

®

ISO HD is a ½ inch thick high density

polyisocyanurate insulation panel specifically

designed for use as a cover/recover board. It is

manufactured on-line using premium performance

coated glass facers.

R-value of 2.5 is significantly higher than roof

cover boards made of wood fiber or gypsum.

Lightweight (11 lbs. per 4 ft. x 8 ft. panel).

Easy to cut, handle and install.

Manufactured with a blowing agent that has

zero ozone depletion potential (ODP) and

virtually no global warming potential (GWP).

Recycled content > 8%.

Compressive Strength > 90 psi.

4 pcf density provides enhanced physical

properties.

Passes ASTM Resistance to Mold Test.

Refer to Table 1 for physical properties.

Recommended Uses:

Mechanically attached Duro-Last

®

roof

systems.

Adhered/Fully Bonded Duro-Last roof systems.

Duro-Bond

®

roof systems.

Metal retrofit roof systems.

Underwriters Laboratories, Inc. Classifications:

Refer to Duro-Last’s UL Listings

(TGFU.R10128) for assembly details.

Factory Mutual Approvals:

FM 4450, FM 4470.

Refer to FM Approval’s RoofNav for details on

FM Approved systems (www.roofnav.com).

Flat Panels:

Available

size:

o 4 ft. x 8 ft.

o 4 ft. x 4 ft.

o Thicknesses: ½ inch.

Installation:

In steel deck applications, Duro-Guard ISO HD

can only be used as a cover board over

insulation or as recover board over an existing

roof. It may be placed directly on flute filler in a

metal roof retrofit application assuming the

flutes are completely filled.

Panels must be kept dry before, during and

after installation. Install only as much insulation

as can be covered the same day with

completed roofing.

The use of multiple layers of insulation with

joints staggered a minimum of 6 inches

between layers is recommended to eliminate

thermal bridging.

Abut panel edges together and stagger joints of

adjacent panels.

Boards must be neatly fitted to roof deck and

around penetrations with no gaps greater than

¼ inch.

Refer to the appropriate Duro-Last roof system

specification and detail drawings for deck

preparation and attachment requirements.

TABLE 1.

PHYSICAL PROPERTIES – COVER BOARD

Compressive

Strength

ASTM D 1621

> 90 PSI

Dimensional

Stability

ASTM D 2126

< .5 % linear change

(7 days)

Water

Absorption

ASTM C 209

< 1% volume

Resistance to

Mold

ASTM D 3273

Passed

Service

Temperature

260° F (126° C) or less