Duro-Last EPS Types II and VIII User Manual

Page 2

Duro-Last, “World’s Best Roof” and Duro-Guard are registered marks owned by Duro-Last, Inc.

Updated: 11/4/2013

2 of 2

www.duro-last.com

800-248-0280

DURO-GUARD

®

EPS TYPES II AND VIII

Installation:

• Duro-Guard EPS panels and Duro-Last

membrane must never be in direct contact.

Refer to the appropriate Duro-Last specification

for slip sheet and cover board requirements.

• Panels must be kept dry before, during and

after installation. Install only as much insulation

as can be covered the same day with

completed roofing.

• The use of multiple layers of insulation with

joints staggered a minimum of 6 inches

between layers is recommended to eliminate

thermal bridging.

• Butt panel edges together and stagger joints of

adjacent panels.

• Boards must be neatly fitted to roof deck and

around penetrations with no gaps greater than

¼ inch.

• Refer to the appropriate Duro-Last roof system

specification and detail drawings for deck

preparation and attachment requirements.

• Precautions must be taken to ensure that new

concrete decks have fully hydrated and do not

continue to release moisture.

Panel Attachment:

• Panels may be attached to the roof deck using

mechanical fasteners or insulation adhesive. It

is acceptable to use these products in

combination.

Mechanical Attachment

• When installing multiple layers (which may

include insulation, cover boards and thermal

barriers) it is acceptable to mechanically secure

through all layers.

• Use fasteners and plates supplied by or

approved by Duro-Last, Inc.

Adhesive Attachment

o

Insulation adhesive must be supplied by

Duro-Last, Inc. Refer to the adhesive’s

product data sheet for application guidelines.

Acceptable products:

o

Duro-Grip

®

Insta-Stik™.

o

Duro-Grip

®

Olybond

®

.

o

Duro-Grip

®

Millenium Weather-Tite

®

.

o

Duro-Grip

®

CR-20.

• Subsequent layers of insulation and approved

cover boards may also be attached with

insulation adhesive.

• Maximum panel dimensions are 4ft. x 4ft.

Storage:

• Insulation must be protected from open flame

and kept dry at all times.

• Factory applied packaging is intended only for

protection during transit. Slit or remove the

packaging to prevent accumulation of

condensation.

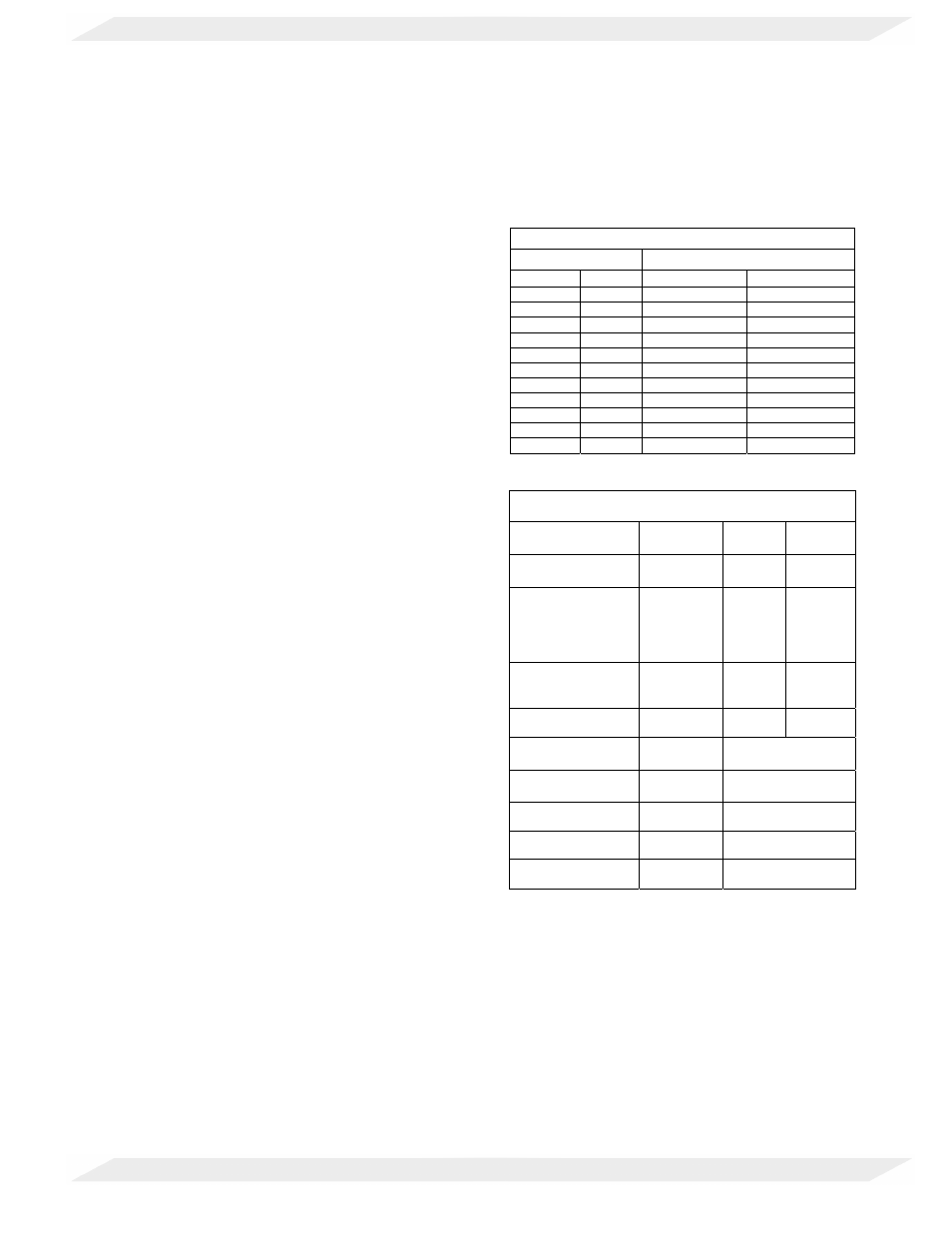

TABLE 2. TYPICAL THERMAL VALUES

THICKNESS* R-Value

inches

mm

TYPE II

TYPE VIII

1.00 25

4.5

4.2

1.50 38

6.7

6.3

2.00 51

9.0

8.4

2.50 64

11.2

10.5

3.00 76

13.5

12.6

3.50 89

15.7

14.7

4.00 102

17.0

16.8

4.50 114

20.2

18.9

5.00 127

22.5

21

5.50 140

24.7

23.1

6.00 152

27.0

25.2

* Contact Duro-Last for additional thickness options.

TABLE 3. TYPICAL PHYSICAL PROPERTIES

Property

Test Method Type II

Type

VIII

Density

(nominal)

ASTM C 303 1.50 pcf

1.25 pcf

R-Value

(per inch)

@25°F

@40°F

@75°F

ASTM C 518

or

C 177

4.76

4.55

4.17

4.55

4.25

3.92

Compressive

Strength

(10% deformation)

ASTM

D 1621

15 – 21

psi

13 – 18

psi

Flexural Strength

ASTM C 203 ≥ 35 psi

≥ 30 psi

Dimensional

Stability

ASTM

D 2126

≤ 2.0%

Water Vapor

Permeance

ASTM E 96

≤ 3.5 perm

Water Absorption

ASTM C 272

≤ 3.0%

Flame Spread

ASTM E 84

20

Smoke Developed

ASTM E 84

150 - 300

• Store elevated (at least 3”) and completely

covered with a weatherproof covering such as

a tarpaulin.

• Do not use panels which are wet or damaged.

Limitations:

• Duro-Last, Inc. will not be responsible or liable

for any defects or problems related to building

or roof design by others, to deficiencies in

construction, to dangerous conditions on the

job site, or to improper storage, handling or

installation by others.