Duro-Last DFP60 Membrane User Manual

Page 2

DURO-FLEECE PLUS 60 MIL MEMBRANE

PRODUCT DATA SHEET

2 of 2

Duro-Last, “World’s Best Roof” and Duro-Fleece are registered marks owned by Duro-Last, Inc.

www.duro-last.com

800-248-0280

Codes and Standards:

Underwriters Laboratories (US & Canada), FM Approvals, ICC-ES (ESR-1660), State of Florida, Miami-Dade

County, Texas Department of Insurance.

Storage:

Store rolls on pallets. Use tarps to keep rolls dry.

Membrane Attachment:

Adhered – DFP60 membrane may be adhered to a variety of properly prepared roof decks, walls, cover boards

and insulations including structural concrete, gypsum, lightweight concrete, DensDeck

®

Prime Roof Board,

SECUROCK

®

Gypsum-Fiber Roof Board, and Duro-Guard

®

ISO products. It may be adhered directly to an

existing built-up roof (BUR) by using Duro-Fleece

®

Adhesive or splatter applied Duro-Grip

®

CR-20. Prior written

approval from the Duro-Last Engineering Services Department is required prior to adhering to BUR. Refer to the

Adhered Duro-Fleece Roofing System Specification for substrate preparation and acceptable adhesives.

Mechanically Fastened – DFP60 membrane may be mechanically attached to a variety of roof deck and wall

materials. An appropriate slip sheet or cover board may be required. Refer to the Duro-Last Mechanically

Fastened Systems Specification for system requirements.

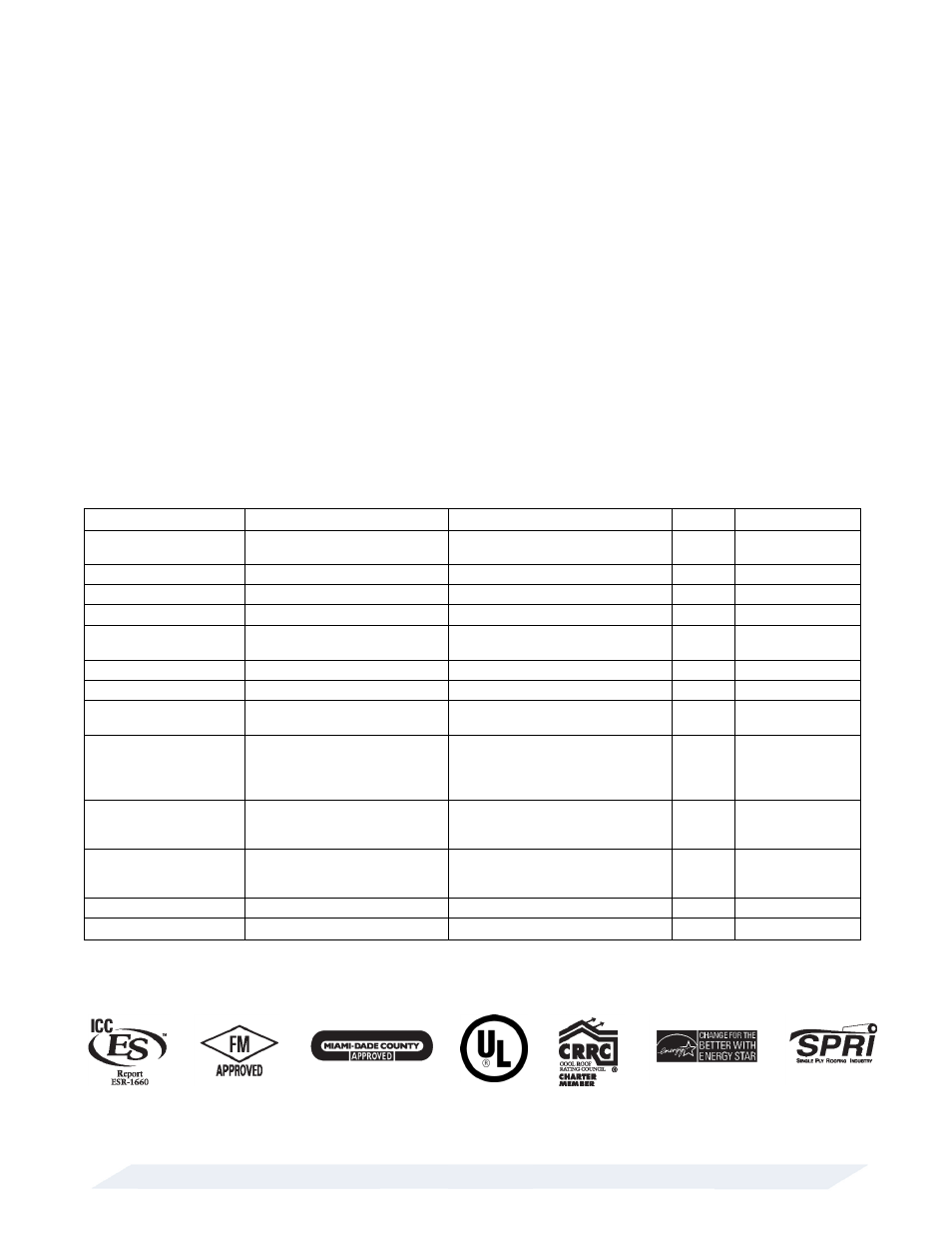

Physical Properties:

DFP60 membrane has been subjected to the tests required by ASTM 4434 “Standard Specification for Poly (Vinyl

Chloride) Sheet Roofing” and has been classified as a Type III, internally reinforced sheet with a fabric backing.

The results of each test as well as typical values are listed below.

Physical Property

Test Method

ASTM 4434 Requirement

Result

Typical Value

Overall Thickness

ASTM D751

≥ 0.045 in.

PASS

60 mil, nominal

(with fleece: 90 mil)

Thickness Over Scrim

ASTM D751

≥ 0.016 in.

PASS 32

mil

Breaking Strength

1

ASTM D751 Grab Method

≥ 200 lbf./in.

PASS

546 lbf x 490 lbf

1

Elongation

1

ASTM D751 Grab Method

≥ 15%

PASS 21%

x

39%

1

Seam Strength

ASTM D 751 Grab Method

≥ 367 lbf.

(75% of Breaking Strength)

PASS 539

lbf

Tear Strength

1

ASTM D751 Procedure B

≥ 45 lbf

PASS

104 lbf x 192 lbf

1

Low Temp. Bend

ASTM D2136

Must Pass at – 40

°F

PASS PASS

Heat Aging

ASTM D3045

Conditioned for 56 days in oven

maintained at 176

°F

PASS PASS

Accelerated Weathering

ASTM G154

(formerly G53)

5,000 hour total test time.

Irradiance level of 0.68 W/m2-nm.

Cycle: 8 hour at 145

°F,

4 hour condensation at 122

°F

PASS PASS

Dimensional Stability

1

ASTM D1204

Conditioned for 6 hours in oven

maintained at 176

°F.

Allowable change: ≤ 0.5%

PASS 0.16%

x

0.16%

1

Water Absorption

ASTM D570

Immersed in water at 158

°F

for 168 hours.

Allowable Weight Change: ≤ 3%

PASS 2.2%

Static Puncture

ASTM D5602

≥ 33 lbf

PASS

≥ 33 lbf

Dynamic Puncture

ASTM 5635

≥ 14.7 ft-lbf (20 J)

PASS

≥ 14.7 ft-lbf

1

Typical values are shown for both machine and cross machine directions. The machine direction results are listed first.