Rainbow Electronics MAX17008 User Manual

Page 30

MAX17007A/MAX17008

Output Capacitor Selection

The output filter capacitor must have low enough effec-

tive series resistance (ESR) to meet output ripple and

load-transient requirements, yet have high enough ESR

to satisfy stability requirements.

In core and chipset converters and other applications

where the output is subject to large-load transients, the

output capacitor’s size typically depends on how much

ESR is needed to prevent the output from dipping too

low under a load transient. Ignoring the sag due to finite

capacitance:

In low-power applications, the output capacitor’s size

often depends on how much ESR is needed to maintain

an acceptable level of output ripple voltage. The output

ripple voltage of a step-down controller equals the total

inductor ripple current multiplied by the output capacitor’s

ESR. The maximum ESR to meet ripple requirements is:

where f

SW

is the switching frequency.

With most chemistries (polymer, tantalum, aluminum

electrolytic), the actual capacitance value required

relates to the physical size needed to achieve low ESR

and the chemistry limits of the selected capacitor tech-

nology. Ceramic capacitors provide low ESR, but the

capacitance and voltage rating (after derating) are

determined by the capacity needed to prevent V

SAG

and V

SOAR

from causing problems during load tran-

sients. Generally, once enough capacitance is added

to meet the overshoot requirement, undershoot at the

rising load edge is no longer a problem (see the V

SAG

and V

SOAR

equations in the

Transient Response

sec-

tion). Thus, the output capacitor selection requires

carefully balancing capacitor chemistry limitations

(capacitance vs. ESR vs. voltage rating) and cost.

Output Capacitor Stability Considerations

For Quick-PWM controllers, stability is determined by the

in-phase feedback ripple relative to the switching frequen-

cy, which is typically dominated by the output ESR. The

boundary of instability is given by the following equation:

where C

OUT

is the total output capacitance, R

ESR

is the

total ESR of the output capacitors, R

CS

is the current-

sense resistance, and A

CS

is the current-sense gain as

determined by the ILIM setting. A

CS

equals 2, 2.67, 4, and

8 for ILIM settings of 5V, 3.3V, 2V, and GND, respectively.

For a 300kHz application, the effective zero frequency

must be well below 95kHz, preferably below 50kHz. For

the standard application circuit with ceramic output

capacitors, the output ripple cannot be relied upon to

be in phase with the inductor current due to the low

ESR of the ceramic capacitors. Stability is mainly

dependent on the current-sense gain. With ILIM = 2V,

A

CS

= 4, and an effective current-sense resistance of

approximately 3.5m

Ω, then the ESR zero works out to:

1/[2

π x (2 x 330μF + 5 x 10μF) x 4 x 3.5mΩ] = 16kHz

This is well within the stability requirements.

R

R

A

R

EFF

ESR

CS CS

=

+

R

f

C

EFF

SW OUT

≥

1

2

f

R

C

SW

EFF OUT

π

π

≥

1

2

R

V f

L

V

V

V

V

ESR

IN SW

IN

OUT

OUT

RIPPLE

≤

(

)

⎡

⎣

⎢

⎢

⎤

⎦

⎥

⎥

-

R

R

V

I

ESR

PCB

STEP

LOAD MAX

+

(

)

≤

Δ

(

)

Dual and Combinable QPWM Graphics

Core Controllers for Notebook Computers

30

______________________________________________________________________________________

MAX17007A

MAX17008

C

OUT

INPUT (V

IN

)

C

IN

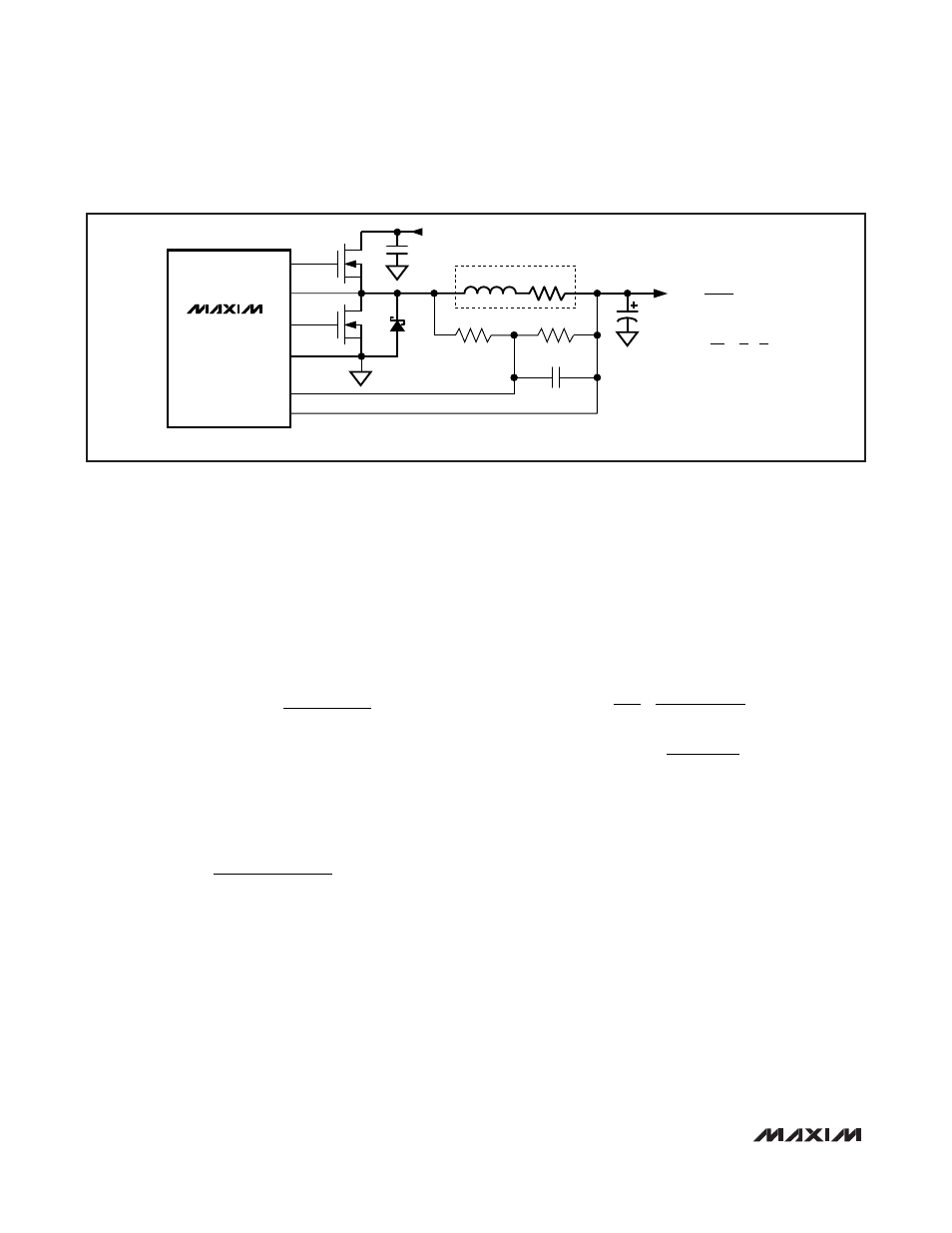

b) LOSSLESS INDUCTOR SENSING

FOR THERMAL COMPENSATION:

R2 SHOULD CONSIST OF AN NTC RESISTOR IN

SERIES WITH A STANDARD THIN-FILM RESISTOR.

CSL_

CSH_

PGND

DL_

DH_

LX_

C

EQ

R1

R2

N

H

N

L

D

L

L

INDUCTOR

R

DCR

R

CS

=

R2

R

DCR

R1 + R2

R

DCR

=

L

[

1 + 1

]

C

EQ

R1 R2

Figure 14. Current-Sense Configurations (Sheet 2 of 2)