Concrete foundation commercial hopper tanks – Grain Systems Bin Accessories PNEG-318 User Manual

Page 128

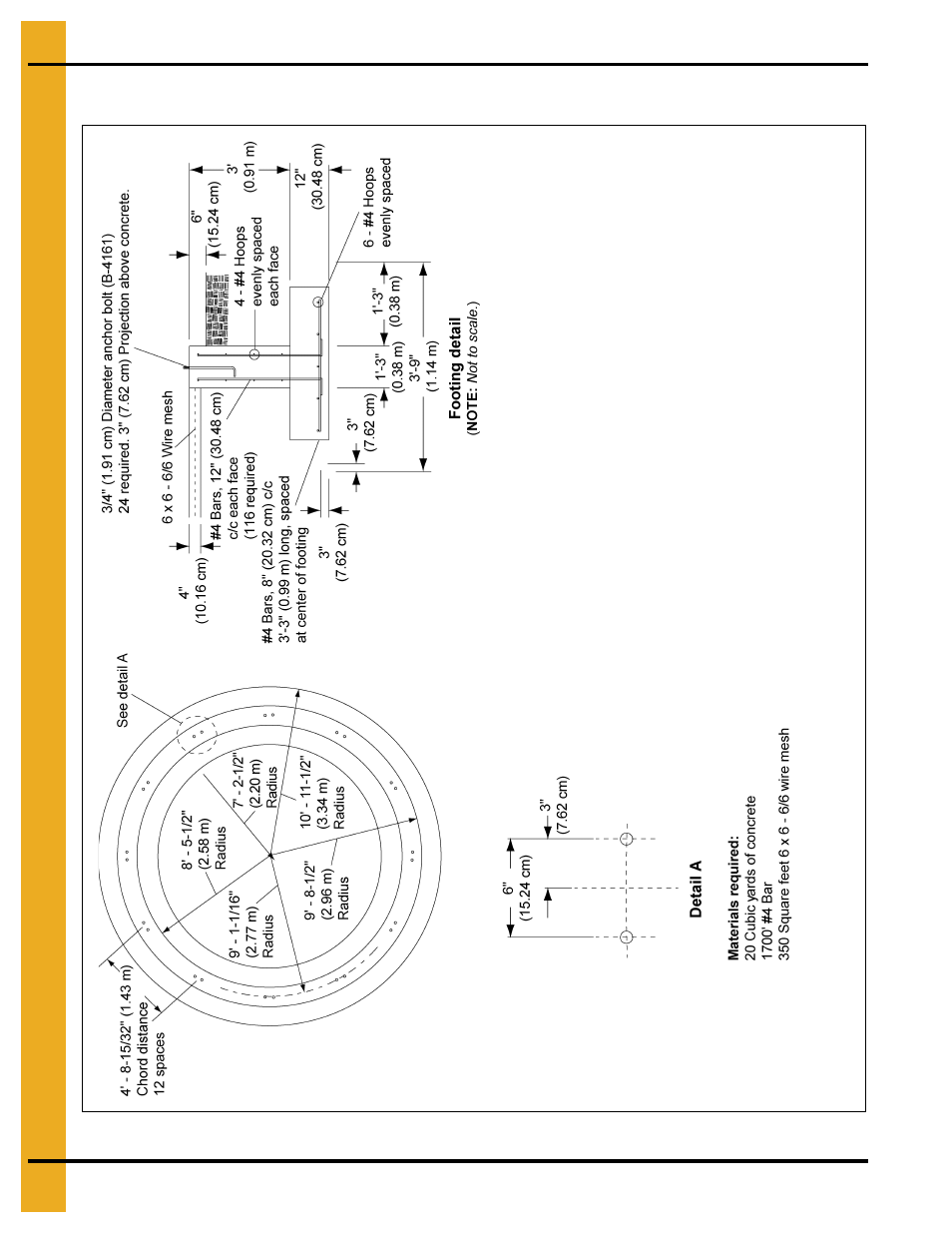

17. Concrete Foundation Commercial Hopper Tanks

128

PNEG-318 Concrete Foundation Recommendations for GSI Grain Bins

18' Diameter Commercial Hopper Tank Foundation up to 12 Rings

Figure 17E

NOTES:

1. T

h

e

foun

dation

d

e

sign

i

s

ba

sed

on a mini

mu

m al

lowa

ble soil

b

earin

g

cap

a

city o

f 3

000

PSF

.

Bearin

g cap

a

city

of th

e soi

ls sho

u

ld

be d

e

termined

by g

eotechn

ical

in

vesti

gation

a

nd be of uniform beari

ng cap

a

ci

ty

.

2. T

h

e

foun

dation

si

te

must b

e

fr

ee

o

f vege

ta

tio

n

and de

bris and

well

d

ra

ine

d.

3. T

h

e

foun

dation

must

be

found

ed

bel

ow

th

e frost line

o

r

con

s

tructed on

non

-e

xp

ansive

frost free

fill.

4.

Al

l ma

te

ri

al used

for backfill

in

si

de the ring

wa

ll shou

ld be clea

n,

we

ll

grade

d,

crushe

d rock

o

r a san

d

-grave

l

mixture. Ba

ckfil

l shoul

d be pla

c

ed

in 6" lif

ts

, 95% comp

action

.

5.

Al

l re

inforcemen

t must

mee

t th

e requi

rement

s

o

f ASTM A615 grad

e 60

deformed ba

rs.

6.

L

ap al

l

ci

rcu

m

fere

nti

a

l bars 35 ba

r

di

ameters

a

nd st

a

gge

r al

l lap

s

in

plan

s 3

'-0"

.

Esti

ma

te

s

do

n

o

t in

clude

e

nd

lap

s

.

7. C

oncrete

must

ha

ve a

min

imum

co

mp

ressive stre

ngth of

3

000 PSI at

28 days, 6%-8% air en

trai

nment,

4

"

slu

m

p.

8.

C

odes: UBC 97,

ACI 318

-9

5.

9. Interio

r top

sla

b

ma

y

be

crow

ned

2"

to

provid

e

water d

raina

ge

awa

y

from found

ation. Crow

ni

ng

the

slab

wi

ll

reduce

the

cle

a

rance

un

der

th

e discharg

e

.